Ash concrete steam-curing kiln control system and steam-curing method thereof

A technology of ash and slag concrete and control system, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of long steam curing process and low steam curing efficiency, and achieve the effects of good effect, uniform heat preservation temperature and balanced temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solution of the invention, the present invention will be further described in detail below in conjunction with specific embodiments.

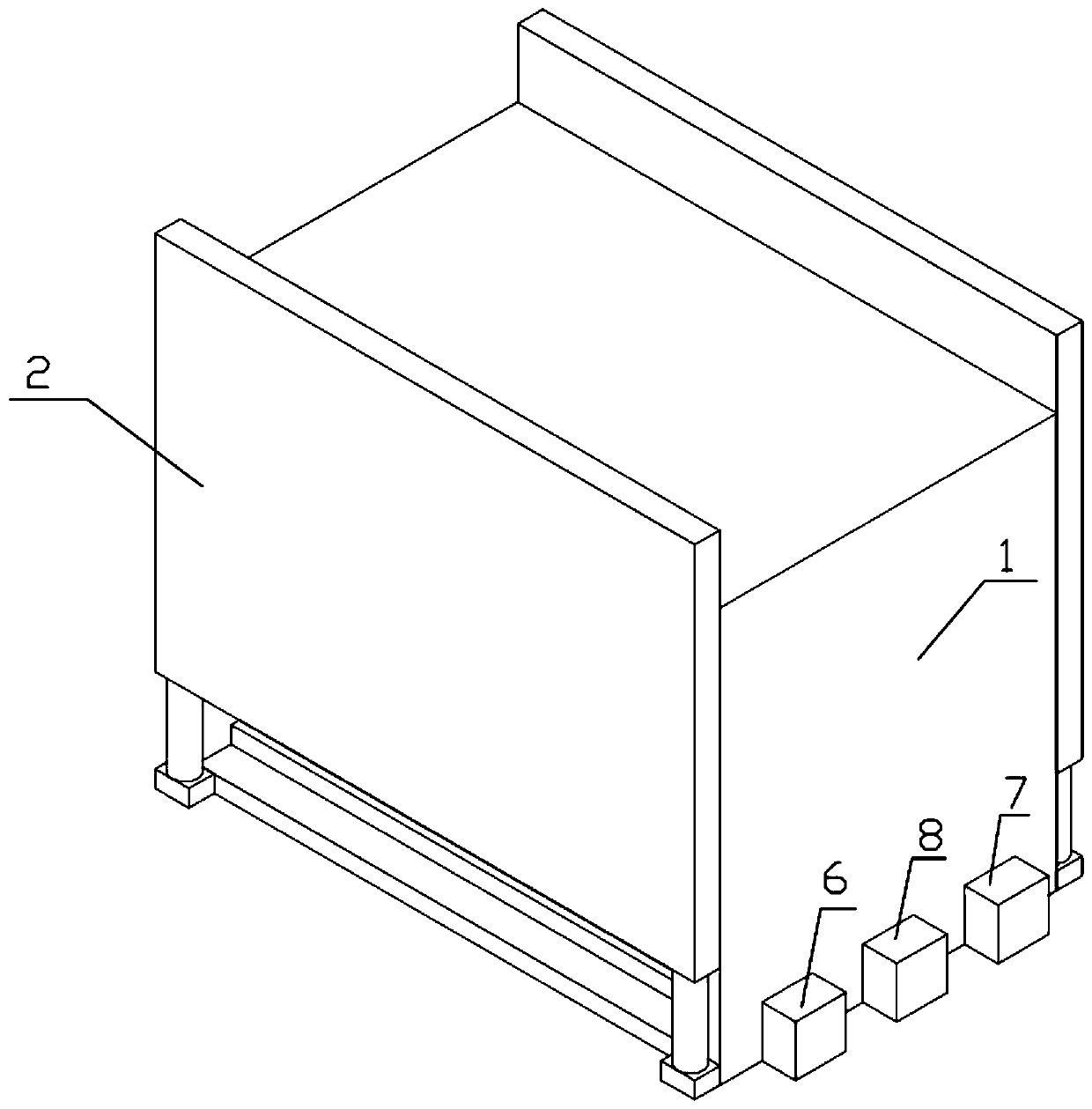

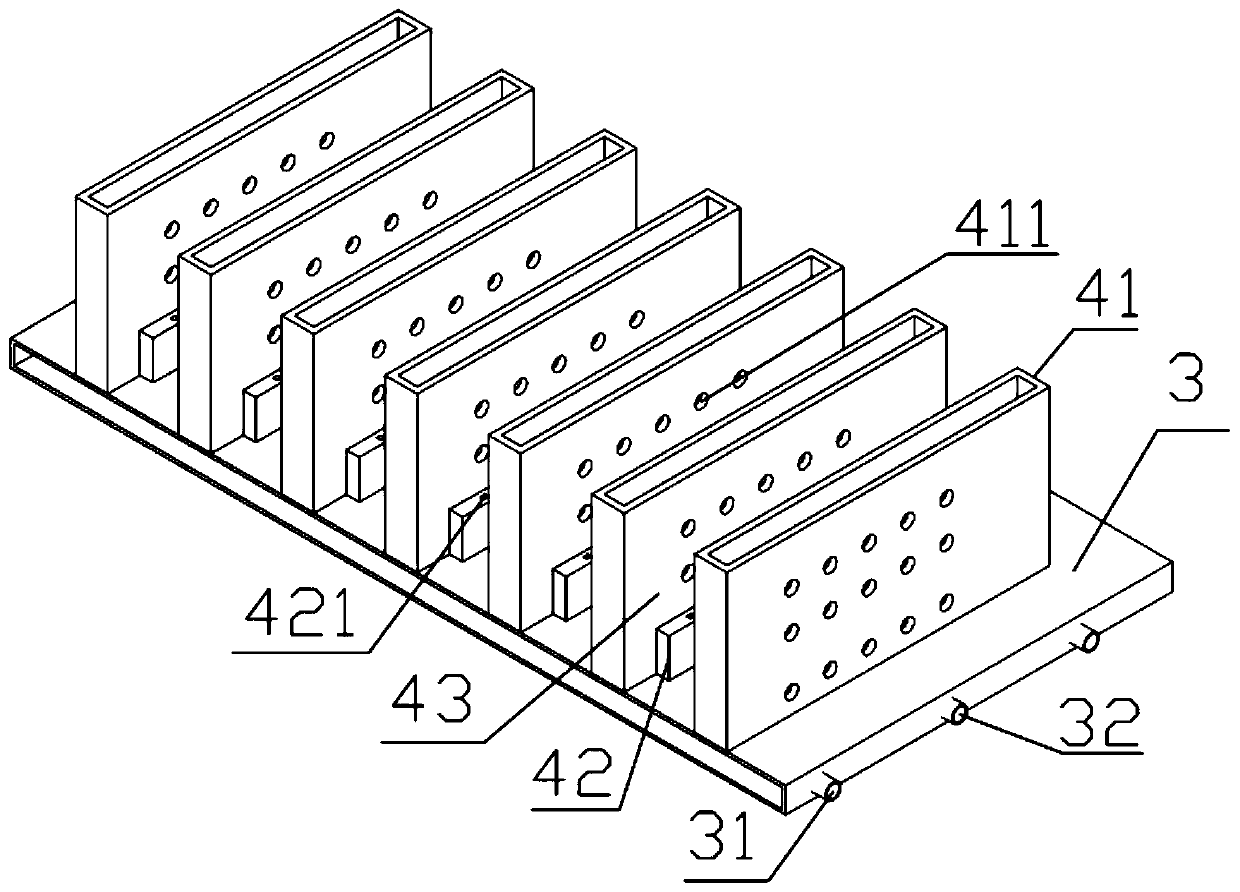

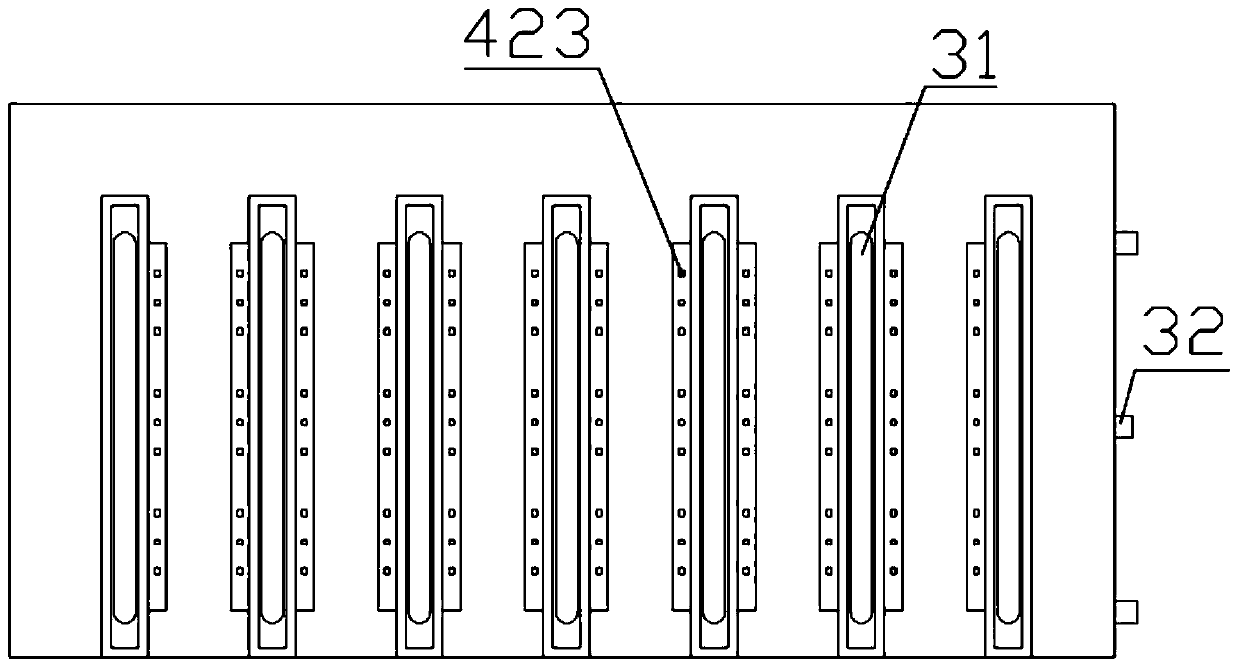

[0034] Such as Figure 1-5 As shown, the present invention firstly provides a control system for a cinder concrete steam curing kiln, including a curing room 1, a curing room door panel 2 arranged on the front and back sides of the curing room 1, a curing panel 3 arranged in the curing room 1, adjacent The steam curing layer 4 separated by the curing plate 3, the ash concrete loading plate 5 adapted to the steam curing layer 4, the oil heat transfer boiler 6 arranged on the side of the curing room 1, the steam supply boiler 7, and the control room 8; Described eutrophication layer 4 comprises heating plate 41 and steam plate 42, and described heating plate 41 divides evaporative layer 4 into a plurality of evaporative chambers 43; Both sides of described heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com