Carrying roll

A technology of guide roller and roller body, applied in the direction of processing textile material carriers, etc., can solve the problems of unevenness, insufficient contact between fabric and steam, poor steaming effect of fabric, etc., and achieve the effect of improving steaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

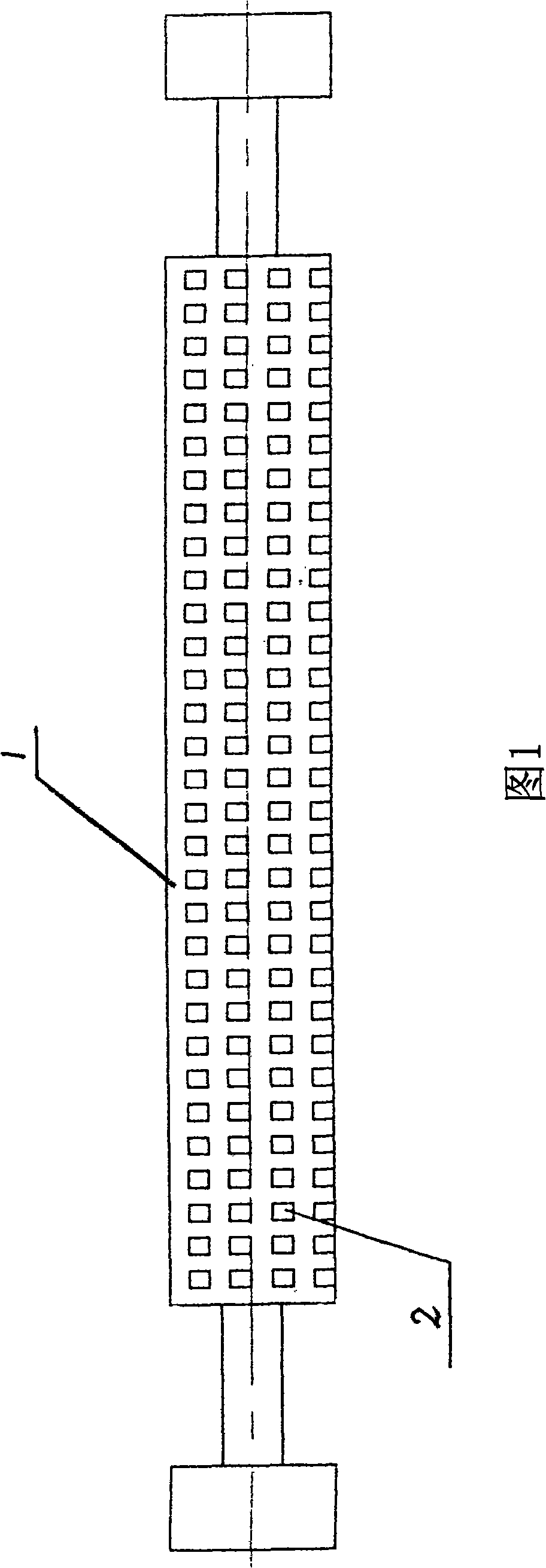

[0010] As shown in FIG. 1 , an embodiment of the present invention is: the guide roller includes a roller body 1 on which a number of ventilation holes 2 are evenly opened. In this embodiment, the through holes 2 are square. Of course, the through holes 2 can also be in other shapes such as circles, triangles, etc., and the through holes 2 can also be arranged unevenly. These changes should all belong to the protection scope of the present invention.

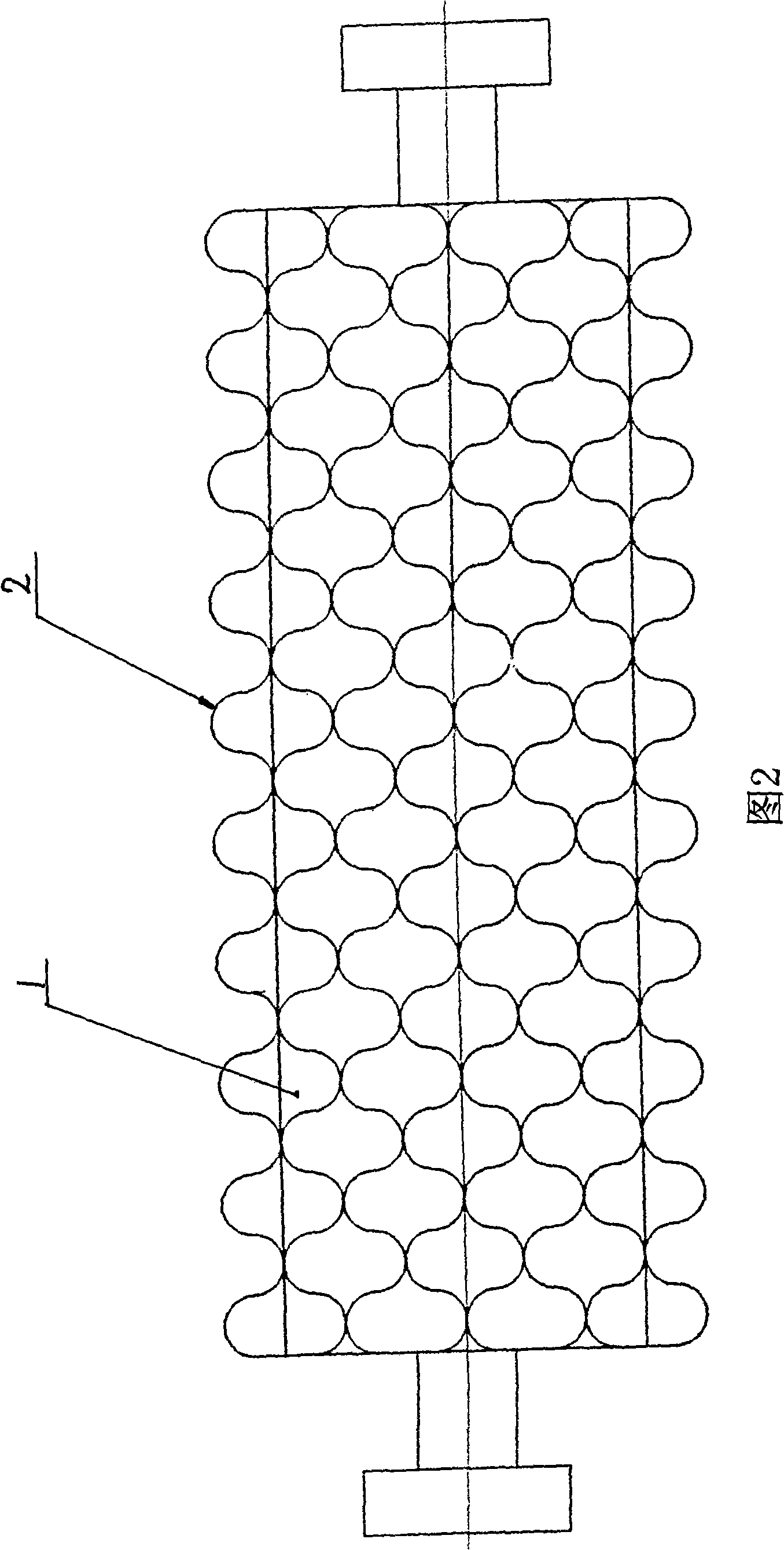

[0011] As shown in Figure 2, another embodiment of the present invention is: the guide roller includes a roller body 1, and a rigid ventilation net 2 is surrounded outside the roller body 1; in this embodiment, the rigid ventilation net 2 is made of stainless steel material, namely the stainless steel ventilation net.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com