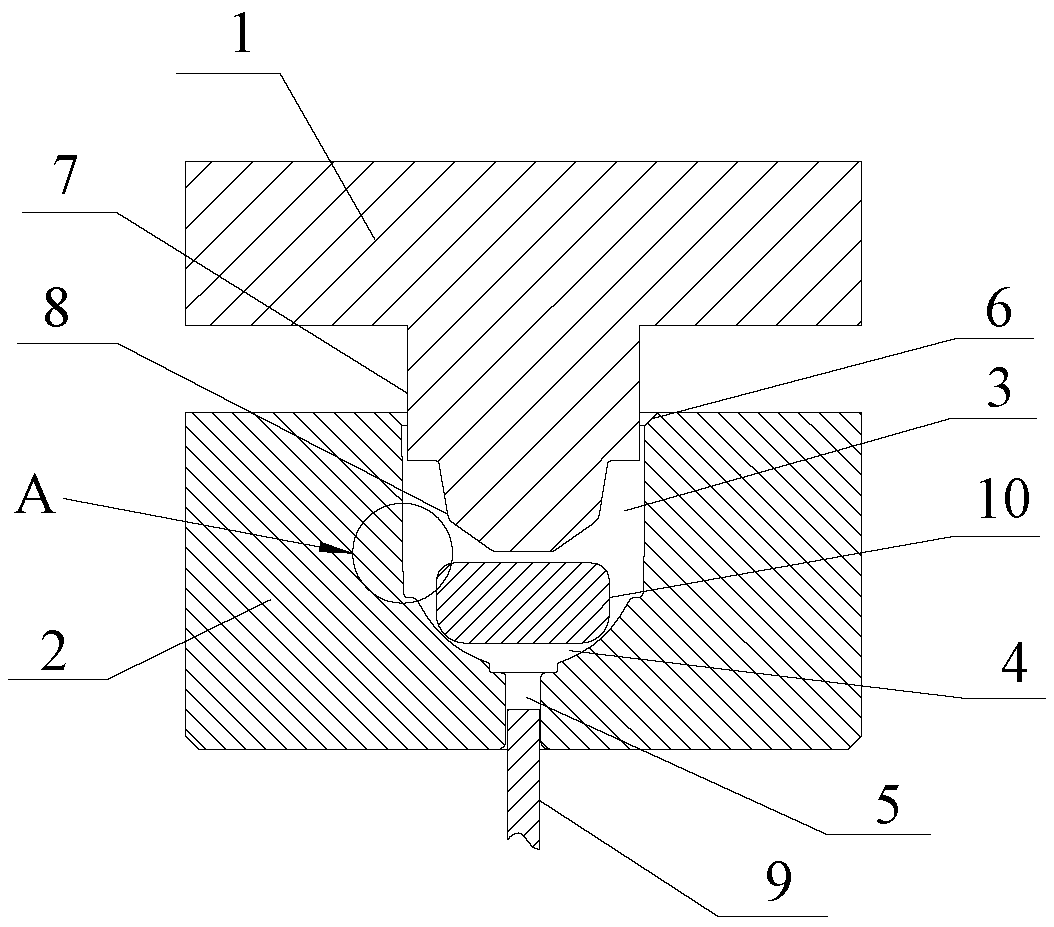

Metal acetabular outer cup closed-type forging die and method

A closed forging and acetabular technology, which is applied to manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of difficult adjustment of forging equipment, low material utilization rate, and high production cost, and save raw materials. , The effect of low input cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

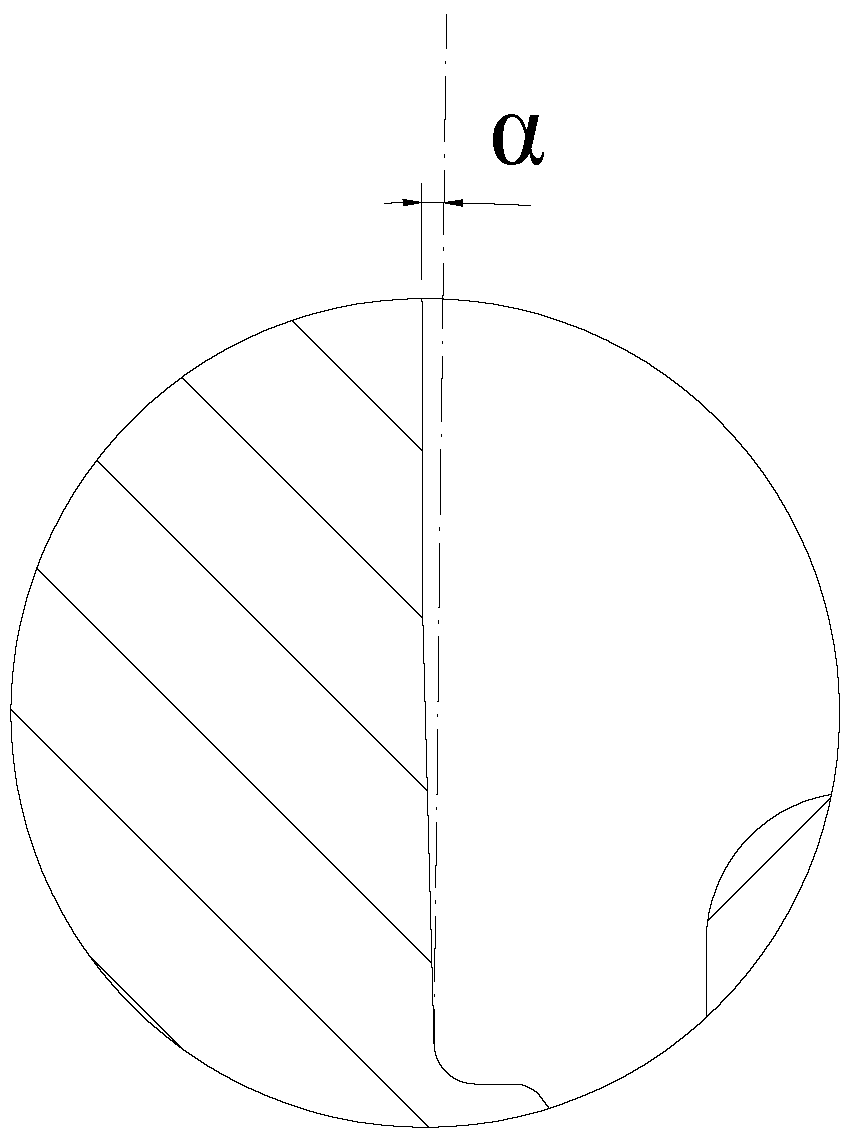

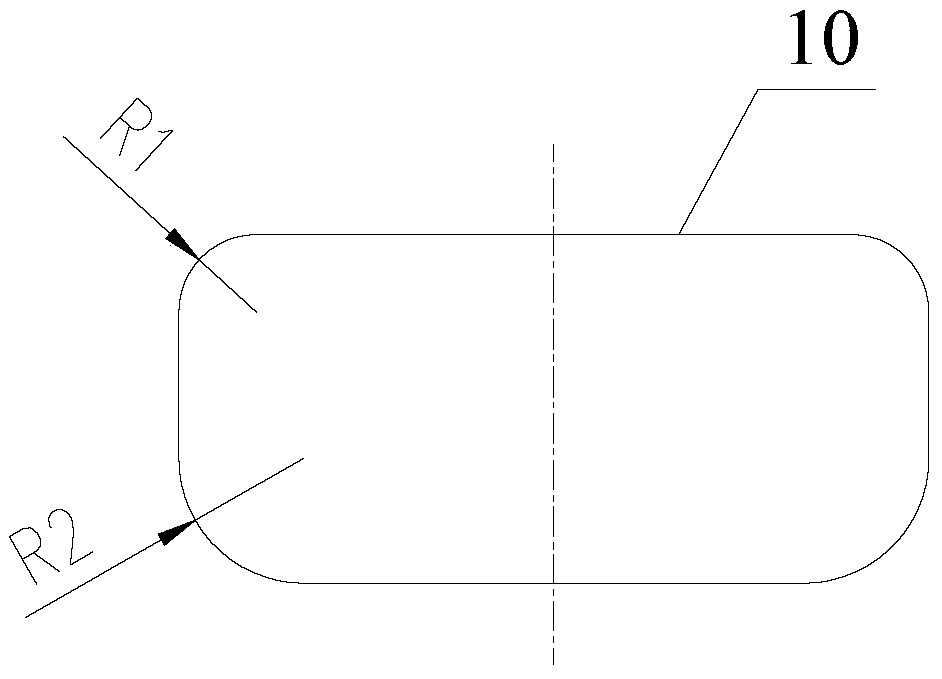

[0036] Step 1, blanking, blank the φ35mm medical Ti6Al4V alloy bar, calculate the length of the bar accurately according to the volume of the acetabular cup, and fillet the upper and lower ends of the bar. The radius of the upper end fillet is R1=3mm, and the lower end is round Corner radius R2=10mm, complete blanking;

[0037] Step 2, spraying, heat the bar to 150°C and directly spray the glass-ceramic anti-oxidation coating, the coating thickness is 0.02mm;

[0038] Step 3, final forging, install the forging die on the electric screw press, the preset thermal expansion coefficient of the die cavity and punch of the forging die is 1.0~1.1, put the bar in step 2 into the electric furnace and heat to 900 ℃, the holding time is 30 minutes, and then take it out and put it into the pre-sprayed graphite mold for final forging to obtain the final forging. The forging direction is downward along the axis of the die cavity.

[0039] The mechanical properties of the final forging prod...

Embodiment 2

[0041] Step 1, blanking, blank the φ45mm medical Ti6Al4V alloy bar, calculate the length of the bar accurately according to the volume of the acetabular cup, and fillet the upper and lower ends of the bar. The radius of the upper end fillet is R1=5mm, and the lower end is round Corner radius R2=8mm, complete blanking;

[0042] Step 2, spraying, heat the bar to 200°C and directly spray the glass-ceramic anti-oxidation coating, the coating thickness is 0.11mm;

[0043] Step 3, final forging, install the forging die on the electric screw press, the preset thermal expansion coefficient of the die cavity and punch of the forging die is 1.0~1.1, put the bar in step 2 into the electric furnace and heat it to 935 ℃, the holding time is 20min, and then take it out and put it into the pre-sprayed graphite mold for final forging to obtain the final forging. The forging direction is downward along the axis of the die cavity.

[0044]The mechanical properties of the final forging produced...

Embodiment 3

[0046] Step 1, blanking, blank the φ40mm medical Ti6Al4V alloy bar, calculate the length of the bar accurately according to the volume of the acetabular cup, and fillet the upper and lower ends of the bar, the radius of the upper end fillet R1=10mm, and the lower end round Corner radius R2=10mm, complete blanking;

[0047] Step 2, spraying, heat the bar to 250°C and directly spray the glass-ceramic anti-oxidation coating, the coating thickness is 0.20mm;

[0048] Step 3, final forging, install the forging die on the electric screw press, the preset thermal expansion coefficient of the die chamber and punch of the forging die is 1.0~1.1, put the bar in step 2 into the electric furnace and heat it to 970 ℃, the holding time is 10 minutes, and then take it out and put it into the pre-sprayed graphite mold for final forging to obtain the final forging. The forging direction is downward along the axis of the die cavity.

[0049] The mechanical properties of the final forging produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com