Magnetic attraction type rotary dust cover for observation window of coal feeder

A technology of dust cover and observation window, applied in the directions of cleaning methods and utensils, pollution prevention methods, chemical instruments and methods, etc., can solve the problems of insufficient pulverized coal, unusable use, coal blockage of coal feeders, etc., and reduce alarms. and non-stop accidents, improve work efficiency, and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

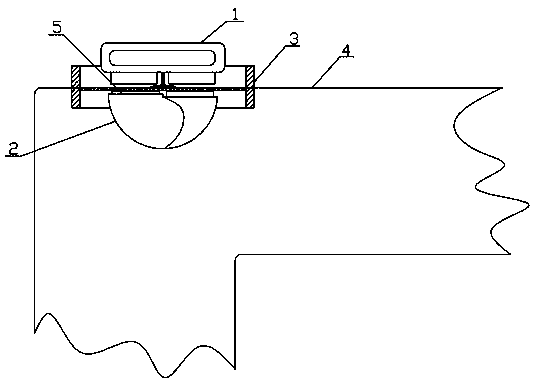

[0022] In order to facilitate the understanding of those skilled in the art, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

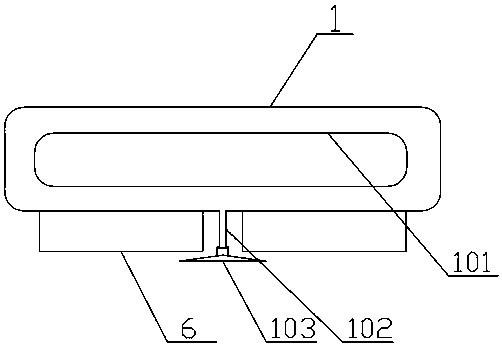

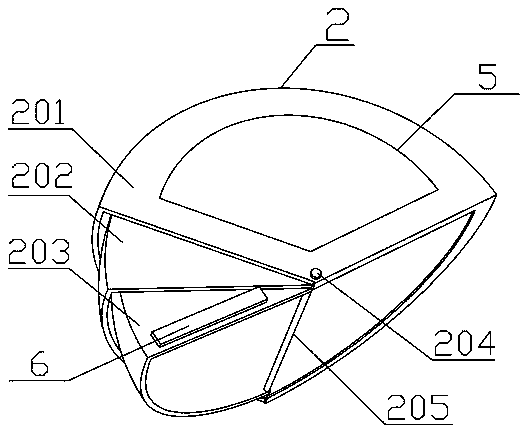

[0023] as attached Figure 1-7 The shown magnetic suction rotating dust cover for the observation window of a coal feeder includes a rotation control device 1, a rotation dust cover 2 and a magnet 6; the rotation control device 1 and the rotation dust cover 2 are respectively provided with a magnet 6 , and under the action of the magnet 6, the rotation control device 1 and the rotation dust cover 2 are magnetically connected to each other.

[0024] The rotation control device 1 includes a handle 101, a support rod 102, a suction cup 103 and a magnet 6; a support rod 102 is provided at the center of the lower part of the handle 101, the bottom of the support rod 102 is connected with the suction cup 103, and the bottom of the support rod 102 is inlaid with the suction cup 103. , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com