Novel composite fuel oil desulfurization adsorbent, preparation method and application thereof

An adsorbent and fuel oil technology, which is applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of poor adsorption selectivity, low adsorption capacity, and low adsorption rate, and achieve high adsorption capacity, large adsorption capacity, and The effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

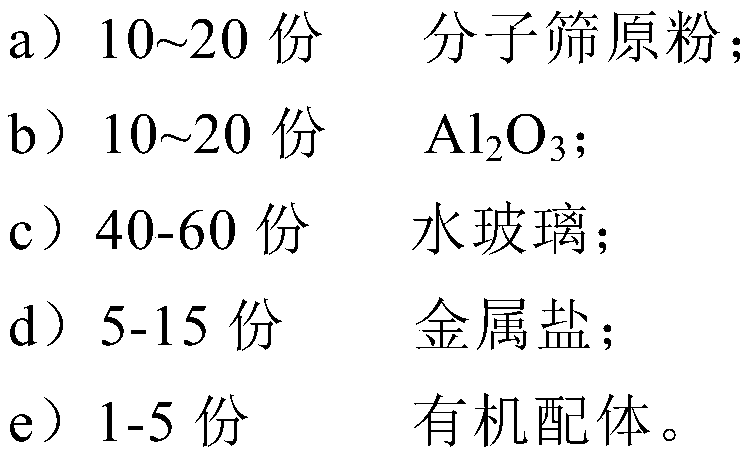

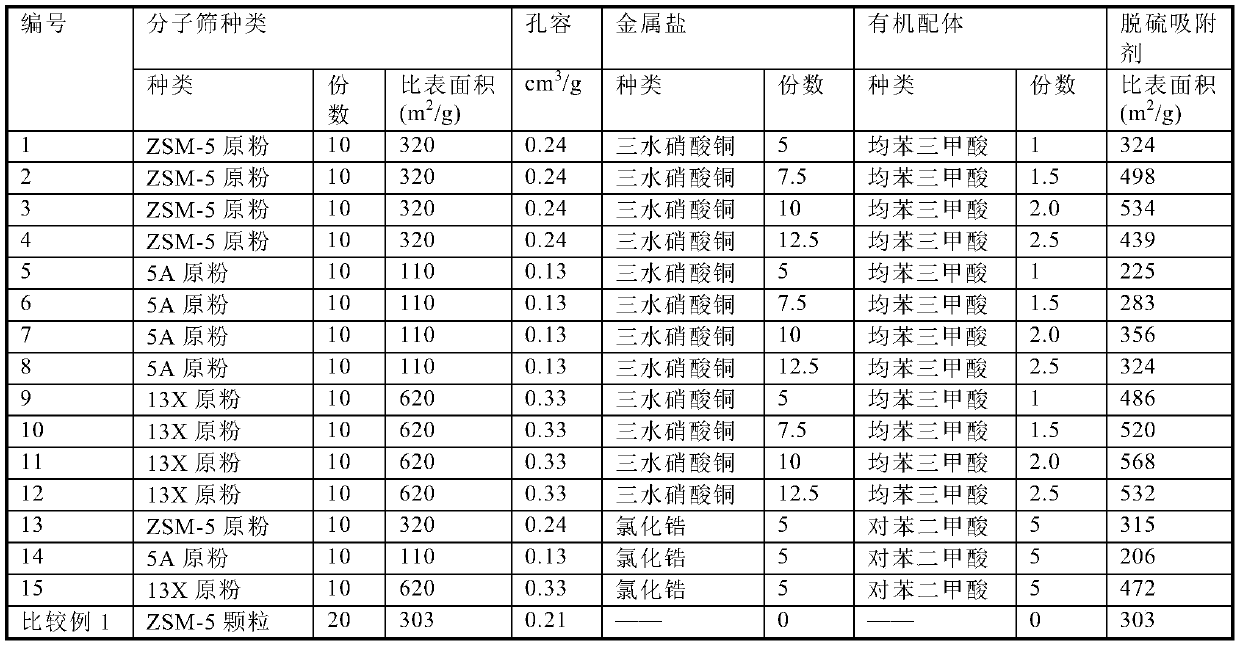

[0041] This embodiment discloses a desulfurization adsorbent, comprising the following components in parts by weight: 10 parts of ZSM-5 raw powder, Al 2 o 3 10 parts, 40 parts of water glass, 5 parts of copper nitrate trihydrate, 1 part of trimesic acid.

[0042] Mix 10 parts of ZSM-5 raw powder with 10 parts of Al 2 o 3 , 0.56 parts of squash gum, and 13.25 parts of citric acid solution were mixed evenly, and extruded by extruder to obtain 40 mesh ZSM-5 particles containing binder. The binder-containing ZSM-5 particles were mixed with water glass, 6 parts of tetrapropylammonium bromide and 140 parts of deionized water, and crystallized at 160°C for 48 hours to obtain binder-free ZSM-5 particles. 2 parts of binder-free ZSM-5 particles were mixed with 5 parts of copper nitrate trihydrate and 1 part of trimesic acid HKUST-1 metal-organic framework mother liquor, and transferred to an 800W microwave hydrothermal synthesizer for 30 minutes at 140 °C. After treatment, the monol...

Embodiment 2

[0045] This embodiment discloses a desulfurization adsorbent, comprising the following components in parts by weight: 10 parts of ZSM-5 raw powder, Al 2 o 3 10 parts, 40 parts of water glass, 7.5 parts of copper nitrate trihydrate, 1.5 parts of trimesic acid.

[0046] Mix 10 parts of ZSM-5 raw powder with 10 parts of Al 2 o 3 , 0.56 parts of squash gum, and 13.25 parts of citric acid solution were mixed evenly, and extruded by extruder to obtain 40 mesh ZSM-5 particles containing binder. The binder-containing ZSM-5 particles were mixed with water glass, 6 parts of tetrapropylammonium bromide and 140 parts of deionized water, and crystallized at 160°C for 48 hours to obtain binder-free ZSM-5 particles. 2 parts of binder-free ZSM-5 particles were mixed with 7.5 parts of copper nitrate trihydrate and 1.5 parts of trimesic acid HKUST-1 metal-organic framework mother liquor, and transferred to an 800W microwave hydrothermal synthesizer for 30 minutes at 140°C. After treatment, ...

Embodiment 3

[0049] This embodiment discloses a desulfurization adsorbent, comprising the following components in parts by weight: 10 parts of ZSM-5 raw powder, Al 2 o 3 10 parts, 40 parts of water glass, 10 parts of copper nitrate trihydrate, 2 parts of trimesic acid.

[0050] Mix 10 parts of ZSM-5 raw powder with 10 parts of Al 2 o 3 , 0.56 parts of squash gum, and 13.25 parts of citric acid solution were mixed evenly, and extruded by extruder to obtain 40 mesh ZSM-5 particles containing binder. The binder-containing ZSM-5 particles were mixed with water glass, 6 parts of tetrapropylammonium bromide and 140 parts of deionized water, and crystallized at 160°C for 48 hours to obtain binder-free ZSM-5 particles. 2 parts of binder-free ZSM-5 particles were mixed with 10 parts of copper nitrate trihydrate and 2 parts of trimesic acid HKUST-1 metal-organic framework mother liquor, and transferred to an 800W microwave hydrothermal synthesizer for 30 minutes at 140°C. After treatment, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com