Distillation tower control method, storage medium and electronic equipment

A control method and a rectification tower technology, applied in the chemical industry, can solve the problems of rectification tower parameter control lag, rectification tower operation stability, rectification tower interference, etc., to improve work efficiency and safety, smooth operation, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

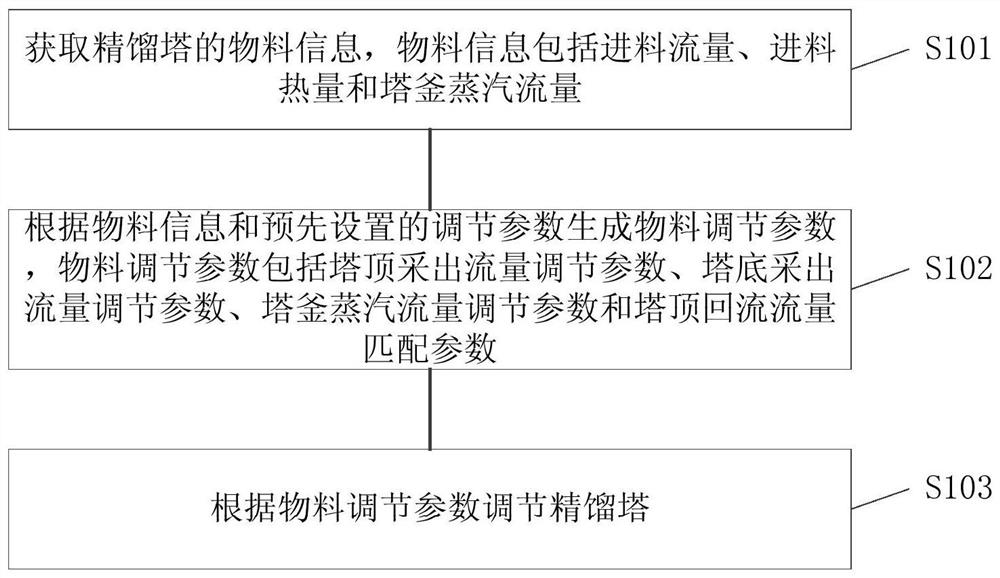

[0079] Such as figure 1 as shown, figure 1 It is a work flow diagram of a rectification column control method provided in Embodiment 1 of the present invention, including:

[0080] Step S101: Acquiring the material information of the rectification tower, the material information includes feed flow, feed heat and column steam flow;

[0081] Step S102: Generate material adjustment parameters based on material information and preset adjustment parameters. Material adjustment parameters include tower top production flow adjustment parameters, tower bottom production flow adjustment parameters, tower bottom steam flow adjustment parameters, and tower top reflux flow matching parameters ;

[0082] Step S103: adjusting the rectification column according to the material adjustment parameters.

[0083] Specifically, when the load of the rectification tower changes, the controller executes step S101 to collect the feed flow rate, feed heat and steam flow of the tower bottom of the re...

Embodiment 2

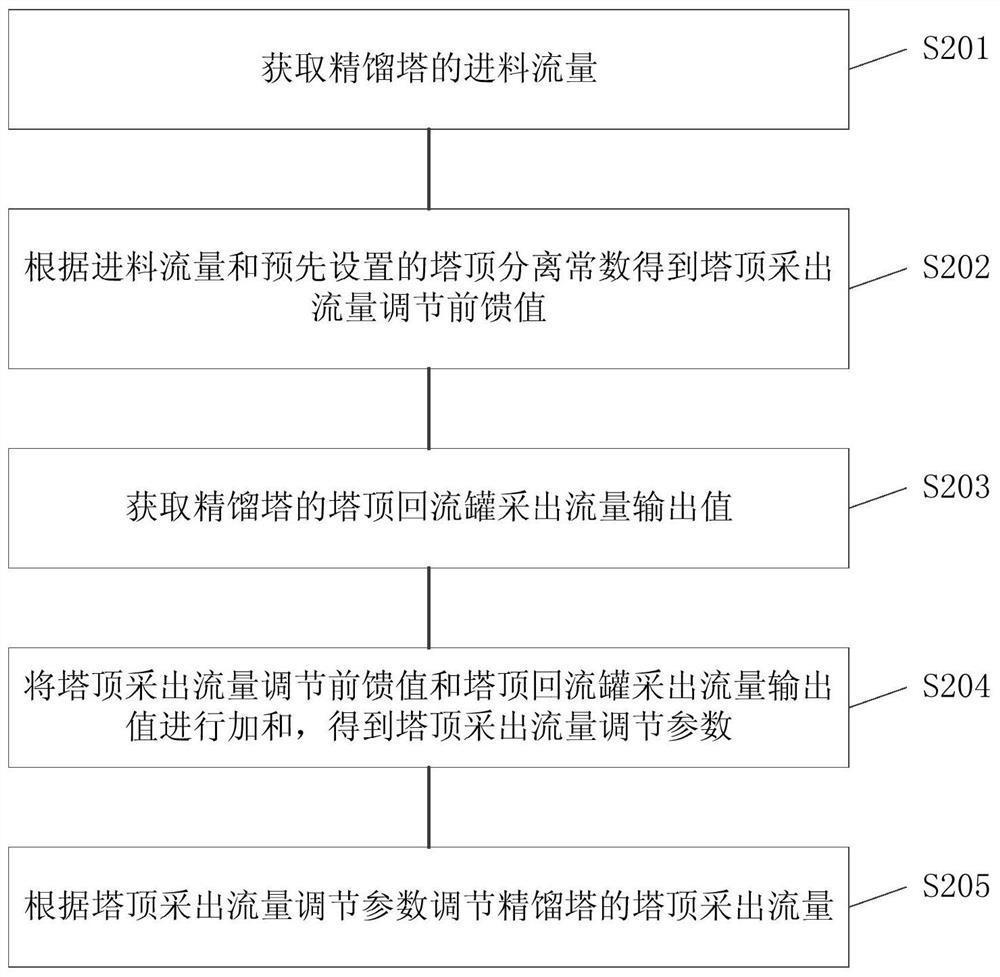

[0087] Such as figure 2 as shown, figure 2 It is a work flow chart of a rectification tower control method provided in Embodiment 2 of the present invention, including:

[0088] Step S201: Obtain the feed flow rate of the rectification tower;

[0089] Step S202: According to the feed flow rate and the preset separation constant at the top of the tower, the feedforward value of the output flow adjustment at the top of the tower is obtained;

[0090] Step S203: Obtain the output value of the production flow rate of the top reflux tank of the rectification tower;

[0091] Step S204: adding the feedforward value of the production flow adjustment at the top of the tower and the production flow output value of the reflux tank at the top of the tower to obtain the adjustment parameter of the production flow at the top of the tower;

[0092] Step S205: adjusting the top production flow of the rectification column according to the adjustment parameter of the top production flow. ...

Embodiment 3

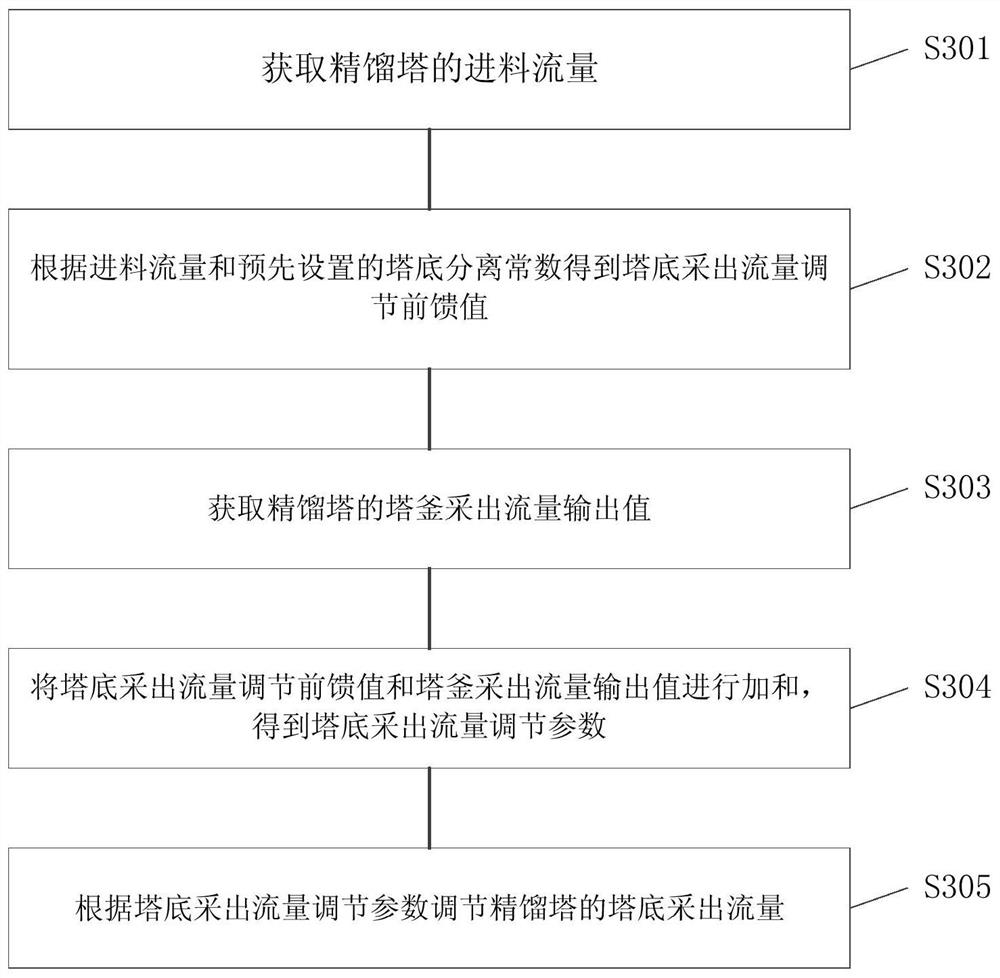

[0109] Such as image 3 as shown, image 3 It is a work flow chart of a rectification column control method provided in Embodiment 3 of the present invention, including:

[0110] Step S301: Obtain the feed flow rate of the rectification tower;

[0111] Step S302: According to the feed flow rate and the preset separation constant at the bottom of the tower, the feedforward value of the output flow adjustment at the bottom of the tower is obtained;

[0112] Step S303: Obtain the output value of the output flow rate of the distillation tower bottom;

[0113] Step S304: adding the feedforward value of the output flow adjustment at the bottom of the tower and the output value of the output flow at the bottom of the tower to obtain the adjustment parameter of the output flow at the bottom of the tower;

[0114] Step S305: adjusting the bottom production flow rate of the rectification tower according to the adjustment parameter of the bottom production flow rate.

[0115] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com