Method for cultivating chlorella by utilizing anaerobic fermentation broth of starch processing wastewater

An anaerobic fermentation liquid and anaerobic fermentation technology, applied in the field of microalgae cultivation, to achieve the effect of high biomass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

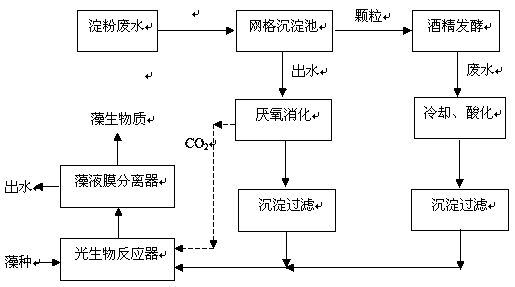

[0031] Such as figure 1 As shown, the present invention utilizes the method for cultivating chlorella of starch processing waste water anaerobic fermentation liquid, is that starch processing waste water is separated particle matter by grid sedimentation tank, and particle matter is fermented and produced alcohol; Grid sedimentation tank effluent is carried out anaerobic fermentation, Then carry out the pretreatment of sedimentation and filtration, after cooling and acidifying the alcoholic fermentation wastewater, carry out sedimentation filtration; after pretreatment, starch anaerobic fermentation wastewater and alcoholic fermentation wastewater are mixed in a certain proportion into the photobioreactor for Chlorella cultivation, Finally, the chlorella and the purified effluent are separated by the algae liquid membrane separator. CO produced by anaerobic fermentation 2 or CH 4 The combustion gas enters the photobioreactor to supplement the carbon source.

[0032] The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com