Underwater grouting measurement device and method for offshore wind power jacket foundation by pile-first method

An offshore wind power and underwater grouting technology, which is used in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as the inability to observe the amount of grouting in real time, the leakage of the grouting material to the steel pipe pile, and the inability to determine the leakage of the grouting. , to achieve the effect of solving the difficulty of grouting amount monitoring, less material consumption, saving manpower, material resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

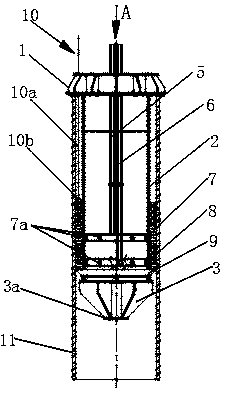

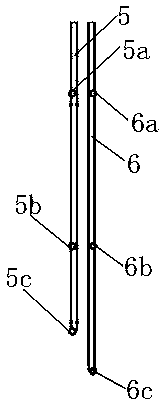

[0020] figure 1 , 2 , 3 shows a structural diagram of an underwater grouting measurement device for offshore wind power jacket foundations using the pile-first method. This underwater grouting measurement device for the offshore wind power jacket foundation of the pile-first method includes a flange 1, a pile leg 2 and a conical head 3, and the conical head 3 is fixed at the end of the pile leg 2 to form a plurality of A rib is connected with the circular plate 3a; it also includes the first grouting pipe 6, the second grouting pipe 5, the first annular cavity 7 and the second annular cavity 8 arranged on the inner wall of the leg 2, the measuring mechanism 10 and the sealing ring 9. Two grouting pipes run through the flange 1 and extend to the inside of the leg 2. The first grouting pipe 6 is provided with a first upper grouting pipe support rod 6a, a first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com