Rotary moving device and using method thereof

A technology of moving device and rotating device, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of inapplicable double-sided engraving, limited processing accuracy, low processing efficiency, etc., to prevent falling boards and improve finished products. Quality, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

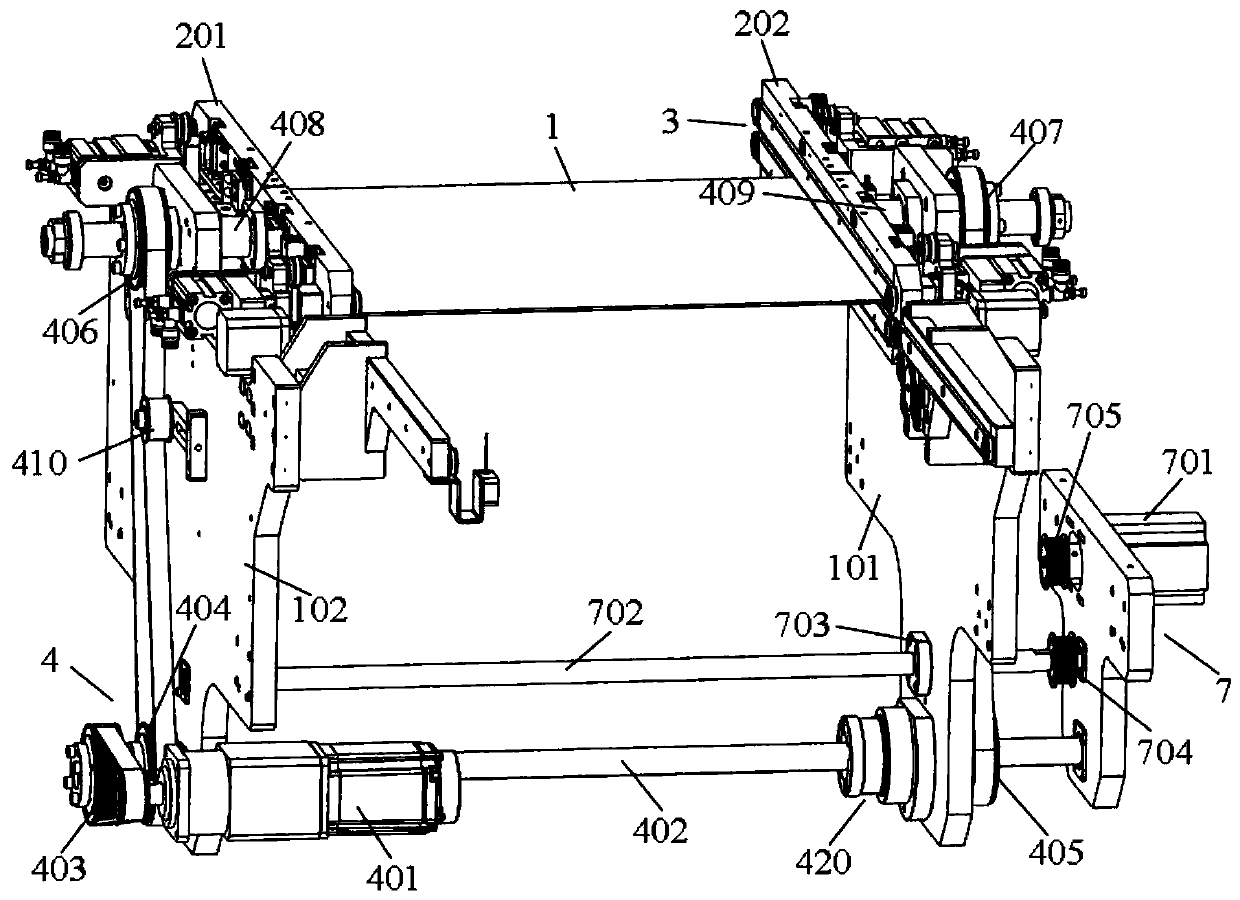

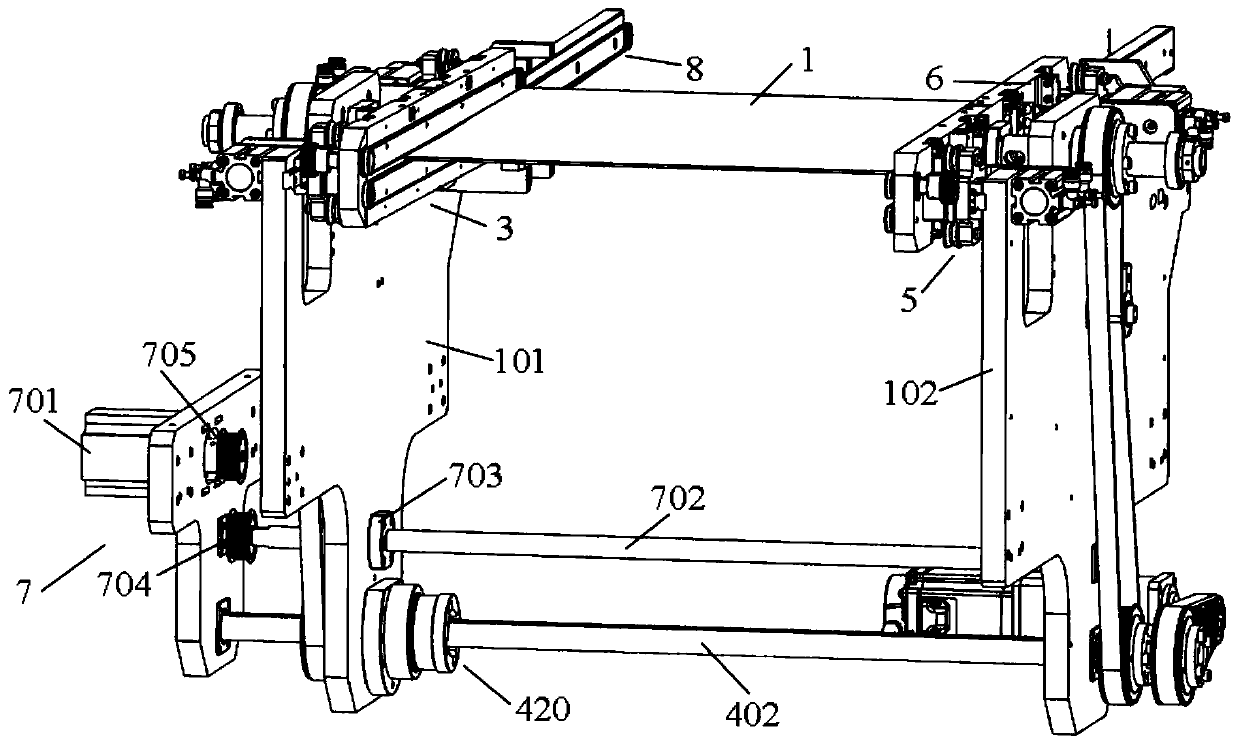

[0067] A rotary mobile device, such as attached figure 1 As shown, including bracket, rotating plate, drive assembly.

[0068] Described support comprises fixed support 102 and mobile support 101, and described rotating plate comprises left rotating plate 201 and right rotating plate 202, and described left rotating plate 201 and right rotating plate 202 are arranged on described fixed support 102, moving support 101 respectively. inside.

[0069] See attached figure 1 , the drive assembly includes a rotating device 4 , a moving device 7 and a transmission device 3 .

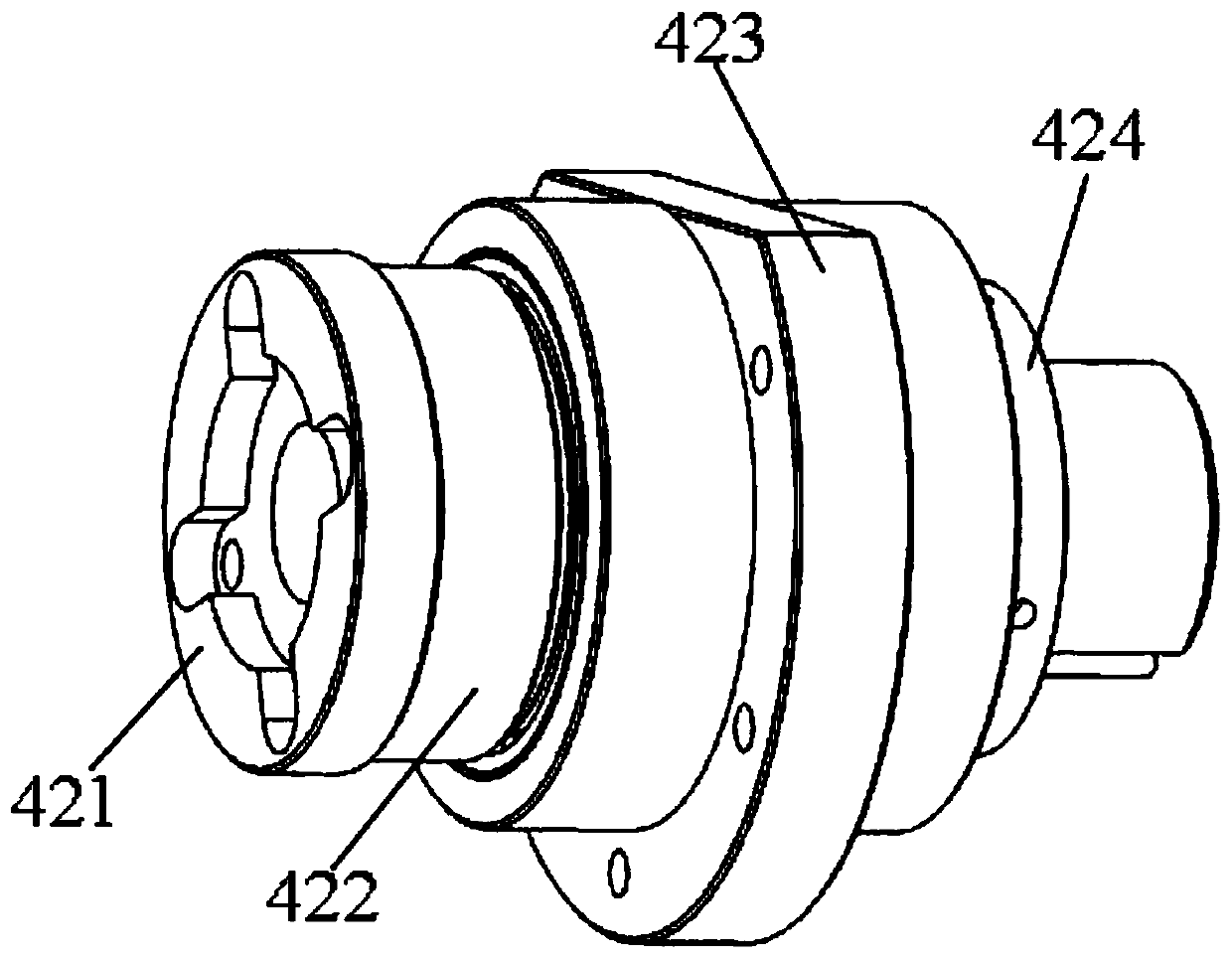

[0070] The rotating device 4 includes a rotating drive motor 401 , a linkage shaft 402 , a transmission wheel, a left rotating roller 408 and a right rotating roller 409 .

[0071] The transmission wheels are located on both sides of the linkage shaft 402, and the transmission wheels are connected by belt transmission. The left rotation roller 408 and the right rotation roller 409 are fixedly connected to the...

Embodiment 2

[0101] Based on the above-mentioned embodiment 1, the similarities will not be repeated, the difference is that the device also includes a positioning device 5, as attached Figure 7 As shown, the positioning device 5 includes a sliding plate 501 , a positioning driving cylinder 502 , a positioning wheel 503 , and a positioning clamping plate 504 .

[0102] The positioning driving cylinder 502 can drive the sliding plate 501 to move left and right, and the positioning driving cylinder 502 is fixed on the moving bracket 101 or the fixed bracket 102 through the connecting plate 508 .

[0103] The positioning wheel 503 is arranged outside the sliding plate 501, and the positioning wheel 503 includes an upper positioning wheel and a lower positioning wheel.

[0104] The positioning clip 504 is fixed on the outer side of the rotating plate through a fixing block 505, and the positioning clip 504 is arranged between the upper positioning wheel and the lower positioning wheel.

[01...

Embodiment 1 and 2

[0114] Based on the above-mentioned embodiments 1 and 2, a method for using a rotating mobile device includes the following steps:

[0115] 101, before the engraving board 1 enters the board, adjust the distance between the fixed bracket 102 and the mobile bracket 101 through the mobile device 7, that is, the mobile drive motor 701 drives the sixth transmission wheel 704 to rotate through the seventh transmission wheel 705 and the belt, and the sixth transmission wheel 704 drives the screw mandrel 702 to rotate, and the screw mandrel 702 drives the screw mandrel nut 703 to move along the screw mandrel 702 at the same time, realizes the movement of the mobile bracket 101, so as to meet the requirement of the walking width of the engraving plate 1;

[0116] 102. After step 101, the engraving plate 1 enters the plate, and the transmission device 3 is turned on, that is, the transmission drive motor 302 drives the transmission belt 301 for transmission, and the transmission belt 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com