Spring telescopic reed

A technology of telescopic reed and spring group, which is applied in the field of spring telescopic reed, can solve the problems of low efficiency, complex structure of telescopic reed, poor durability, etc., and achieve the effect of uniform and stable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

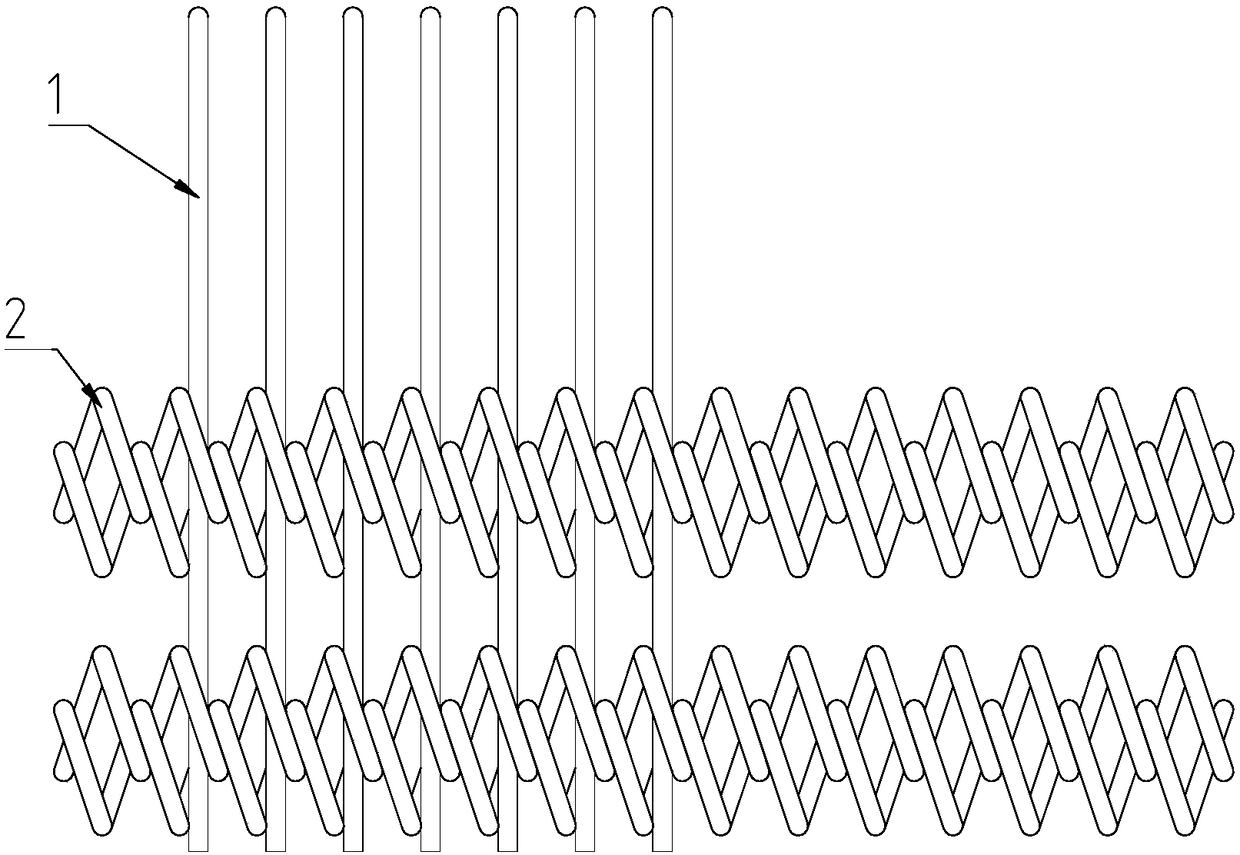

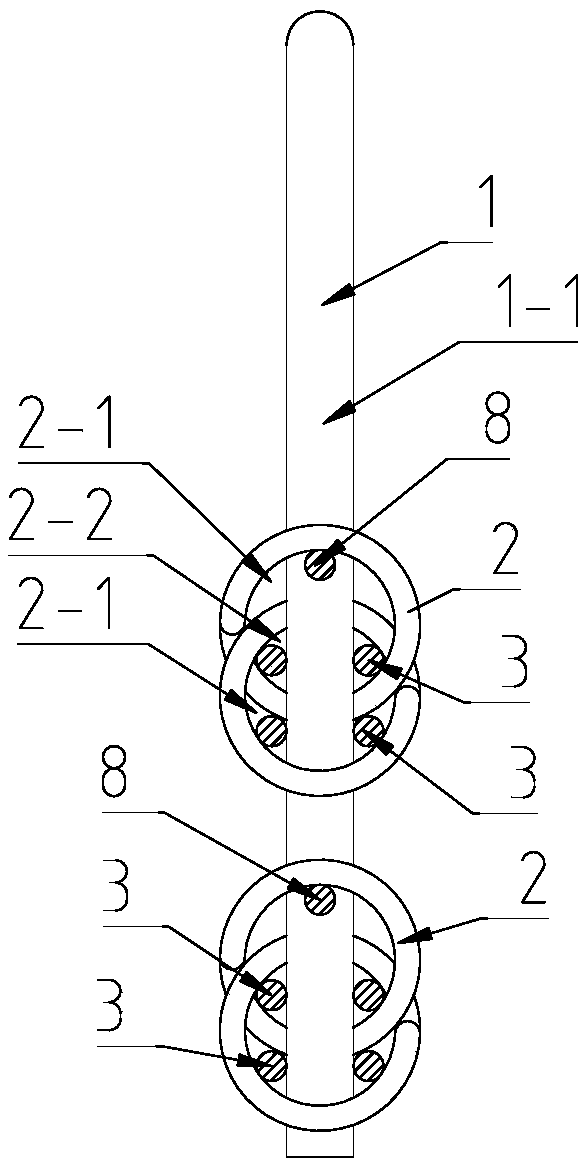

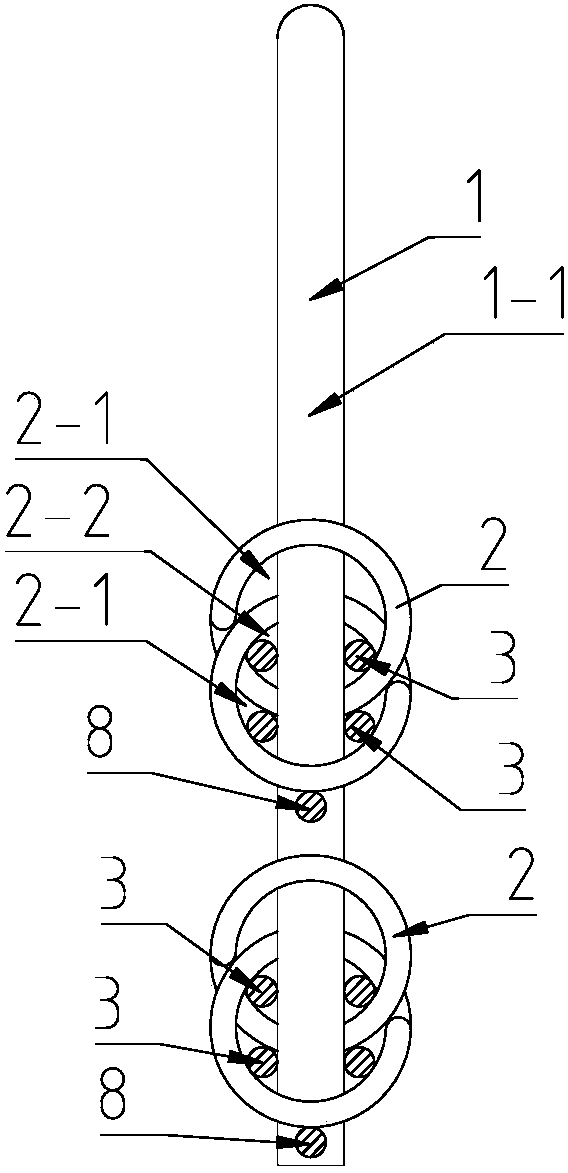

[0062] Example 1, such as figure 1 , 2 , 3, 4, 5, 6, 7, 8 and 9:

[0063] A spring telescopic reed, comprising a base 4, a telescopic drive mechanism, a spring group 2 and a reed needle row, wherein the reed needle 1 of the reed needle row is a straight flat reed needle and includes a needle bar part 1-1. The top surface of the base 4 has a needle groove 7 extending along the length direction of the base 4, and the telescopic drive mechanism and the spring group 2 are installed in the inner cavity of the base 4 in parallel along the length direction of the base 4. The reed needles of the reed needle row 1 are all positioned by the way that the needle bar part 1-1 penetrates into its supporting two or more coils of the spring group 2 arranged in a straight line up and down on the vertical plane, and passes through the base 4 from the needle groove 7.

[0064] The two adjacent coil springs in each spring group 2 are fitted and connected by interlocking each other's spring coil...

Embodiment 2

[0081] Example 2, such as Figure 10 , 11 and 12 as shown:

[0082] This embodiment 2 compares with embodiment 1, and difference point is: reed needle 1 comprises needle bar part 1-1 and beam part 1-2, has socket 1-2-1 on beam part 1-2, needle bar part 1-1 through the socket 1-2-1 through the crossbeam part 1-2, the reed needle 1 passes through the needle bar part 1-1 and the crossbeam part 1-2 respectively into the spring set 2, or the reed needle 1 only passes through the crossbeam part 1-2 thread into spring group 2.

Embodiment 3

[0083] Example 3, such as Figure 13 Shown:

[0084] This embodiment 3 is compared with embodiment 1, and the difference is: the reed needle 1 comprises a needle bar part 1-1 and a side arm part 1-3 extended from one side or both sides of the needle bar part 1-1, and the reed Either the needle 1 penetrates the spring set 2 via the needle shank part 1-1 and the side arm part 1-3 respectively, or the reed needle 1 penetrates the spring set 2 only via the side arm part 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com