Buoyancy lift measuring device for underwater thermal jet

A measuring device and thermal jet technology, which is applied in the direction of measuring device, machine/structural component testing, fluid dynamics test, etc., can solve problems such as heat loss, large error, and damage to the buoyant form of thermal jet, so as to improve measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

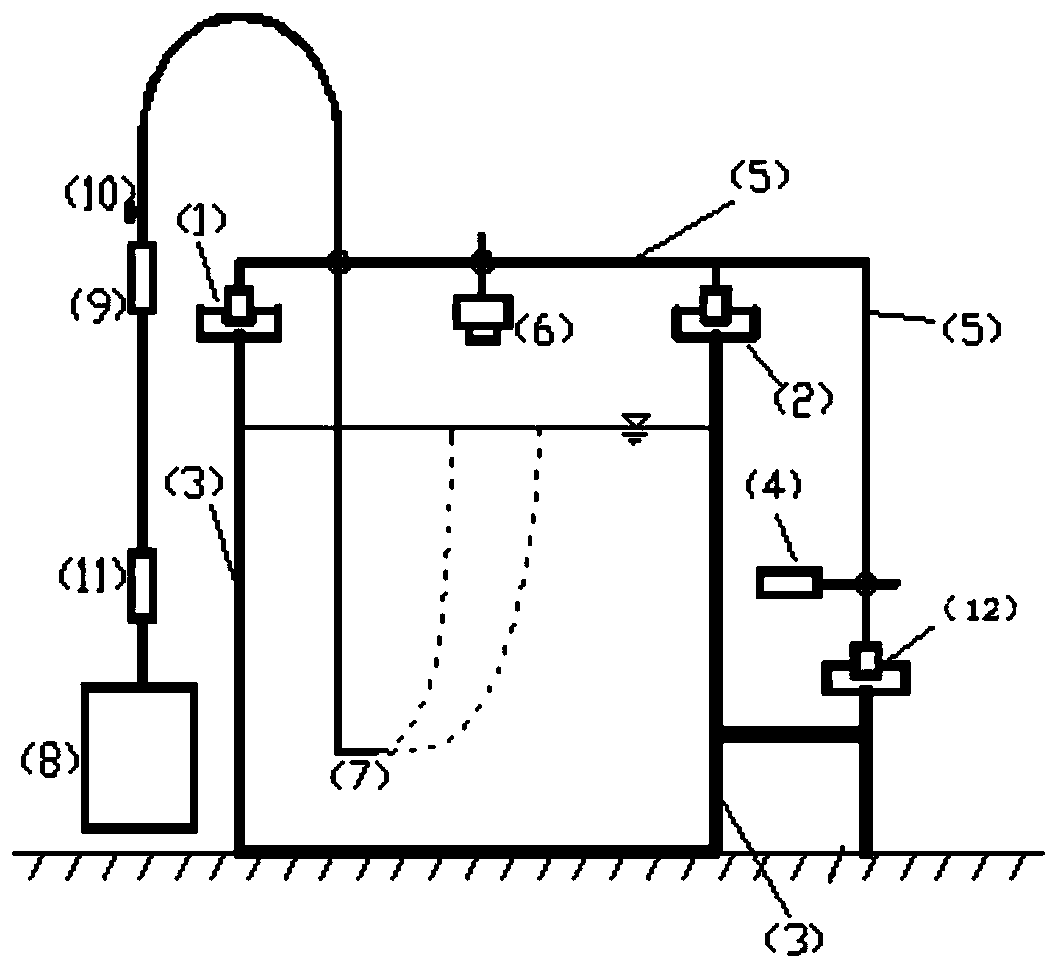

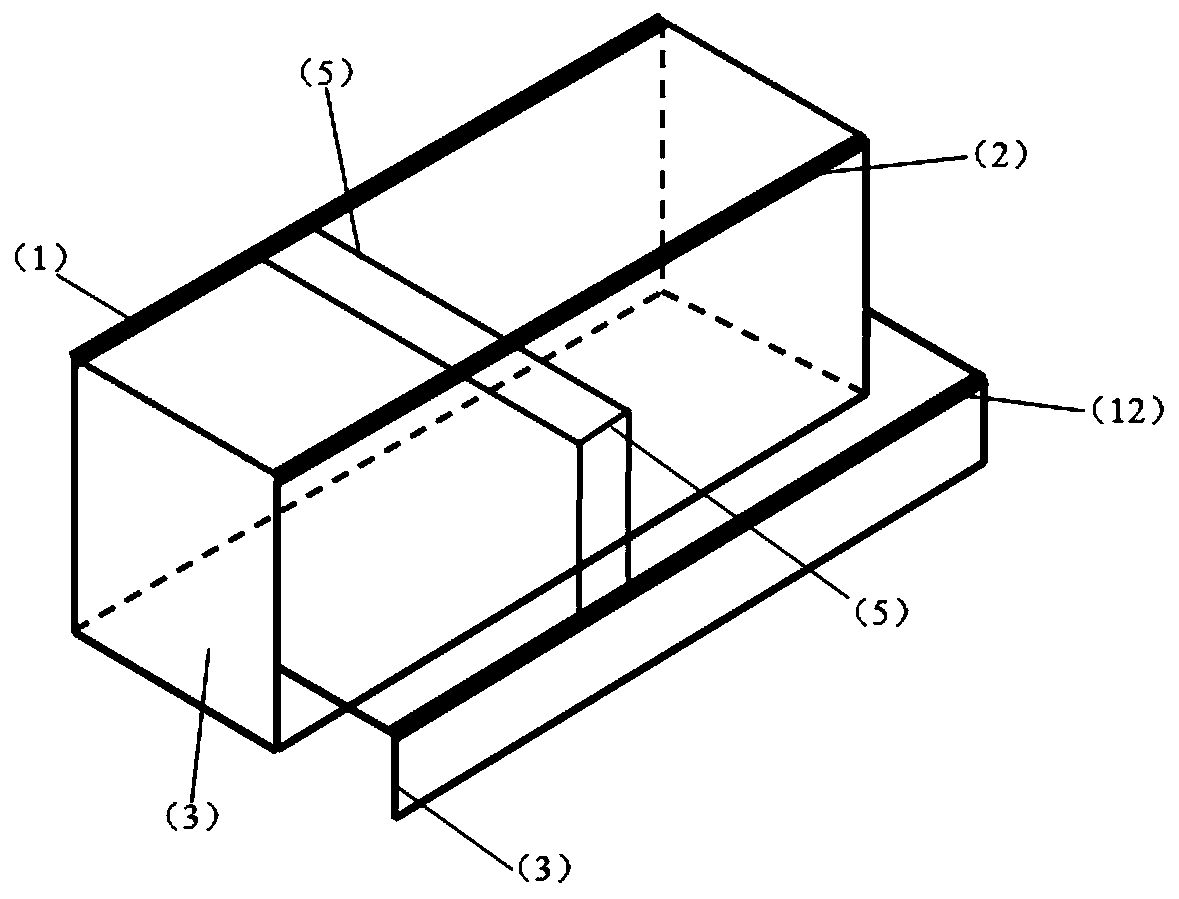

[0019] The prerequisite for flow similarity is that the dimensionless numbers are equal. Under the condition that the Archimedes number and the Grashof number are the same, the mass transfer process and the heat transfer process have exactly the same flow differential equation, so the analogy of the mass transfer process can be measured Get the heat transfer process. The underwater thermal jet buoyancy measuring device of the present invention uses the method of planar laser-induced fluorescence to perform non-contact measurement on the buoyancy process of the thermal jet. The jet medium can be selected to be soluble in water, but the liquid with a lower density than water, such as alcohol And water solution, adjusting its concentration, can make the Archimedes number equal to the Grashof number of the corresponding heat transfer experiment. Before the test starts, rhodamine at an appropriate concentration should be pre-added in the jet medium as a fluorescent material, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com