Road crack sealing machine with self-cleaning function

A seam filling machine and self-cleaning technology, used in roads, roads, road repair and other directions, can solve the problems of inconvenient cleaning, difficult to remove asphalt, inconvenient to use, etc., and achieve the effect of convenient scraping, good effect, and prevention of movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

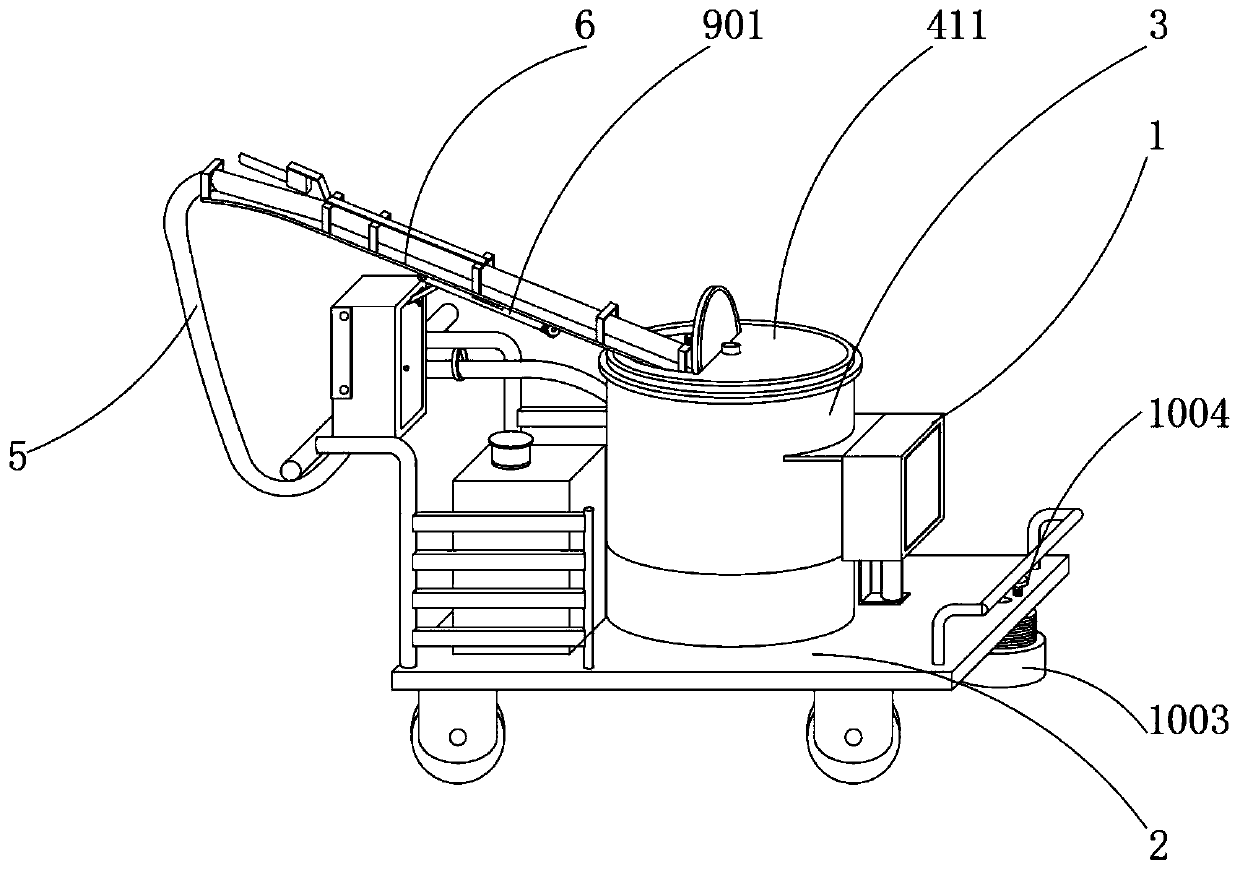

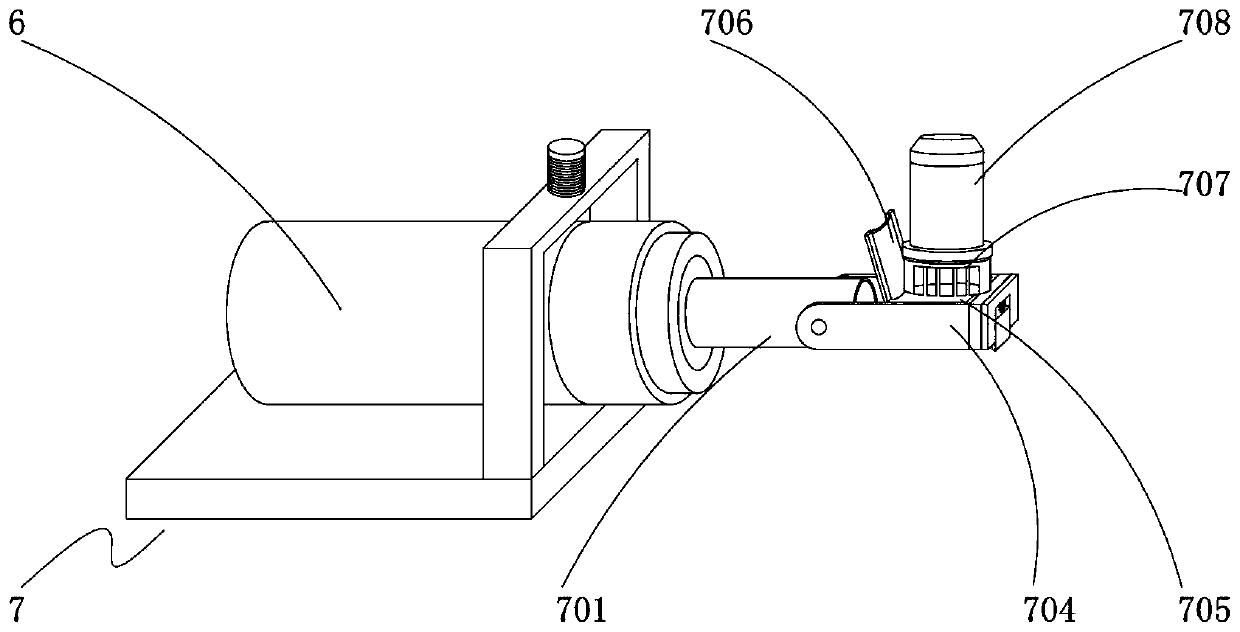

[0044] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a road joint filling machine with self-cleaning function, comprising a joint filling machine body 1, a base plate 2 is arranged at the bottom of the joint filling machine body 1, and an asphalt hot melting tank is installed on the top of the base plate 2 3. An asphalt pipe 5 is installed on one side of the bottom of the asphalt melting tank 3, and the middle part of the asphalt pipe 5 is sleeved with a support frame 6 to facilitate the flow of melted asphalt;

[0045] A cleaning assembly 4 is installed inside the asphalt hot melting tank 3, and the cleaning assembly 4 includes a stirring shaft 401, an installation groove 402, a connecting block 403, an installation pipe 404, a chute 405, a first cleaning pipe 406, a positioning groove 407, and a second cleaning pipe 408, connecting pipe 409, water inlet pipe 410 and case cover 411;

[0046] The stirring shaft 401 is rotatably in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com