A wood slotting device for the production of student tables and chairs

A technology for wood boards, tables and chairs, which is used in slotting machines, feeding devices, and mortising machines, etc., can solve the problems of not being able to control the depth of the slotting of the wood, affecting the slotting of the wood, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

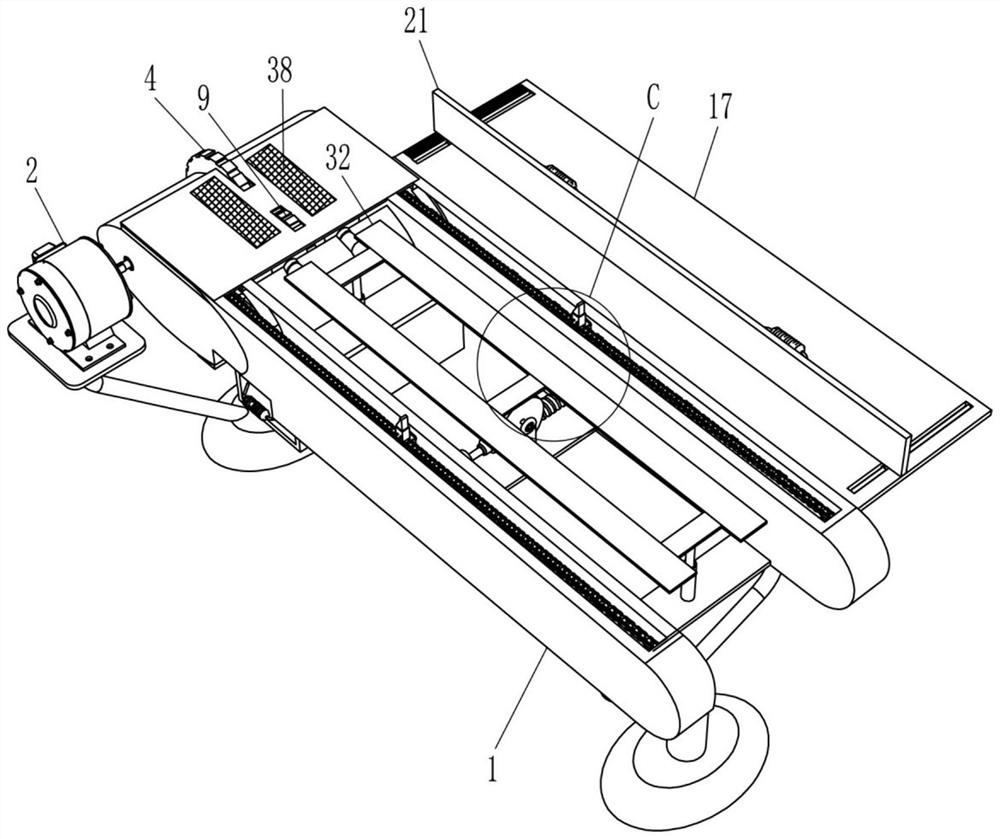

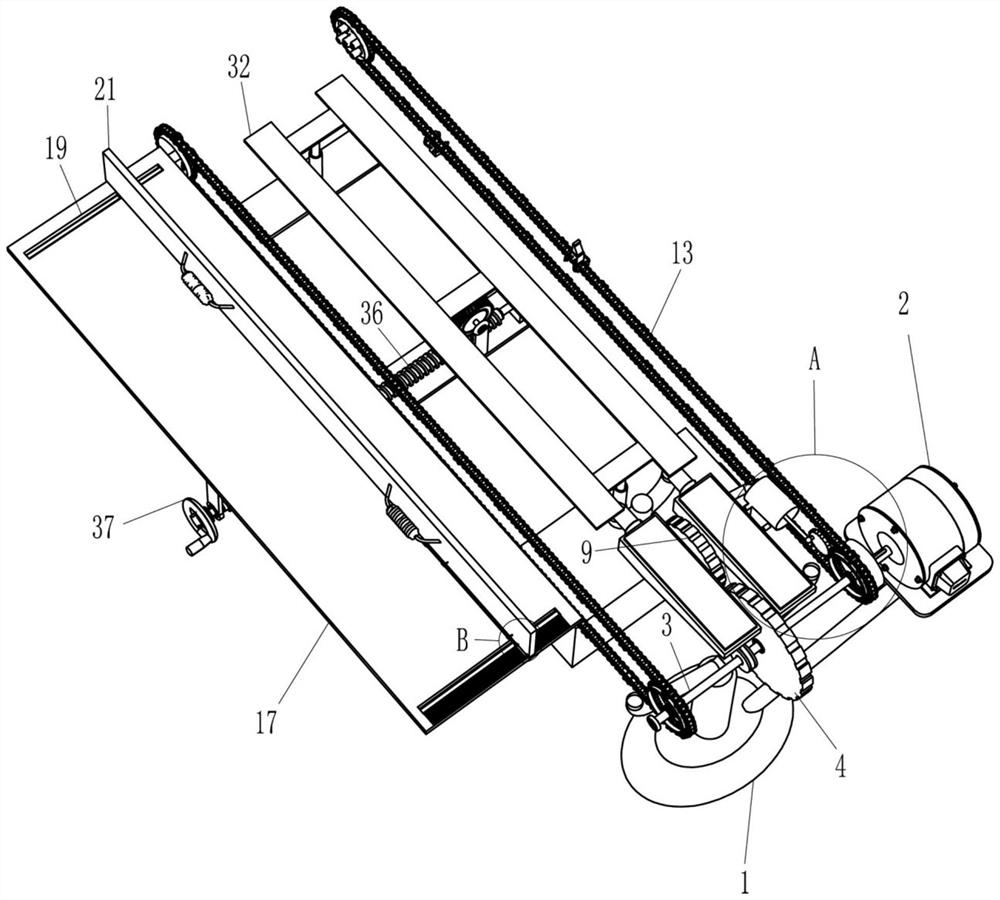

[0025] A wood slotting device for the production of student desks and chairs, such as Figure 1-6 As shown, it includes a mounting frame 1, a slotting assembly, a pushing assembly and a moving assembly. The left part of the mounting frame 1 is provided with a slotting assembly for slotting the plank by rotating, and the rear side of the mounting frame 1 is provided with a sliding method. The pushing component for pushing the wooden board back and forth, the installation frame 1 is provided with a moving component for laterally moving the wooden board by means of pushing.

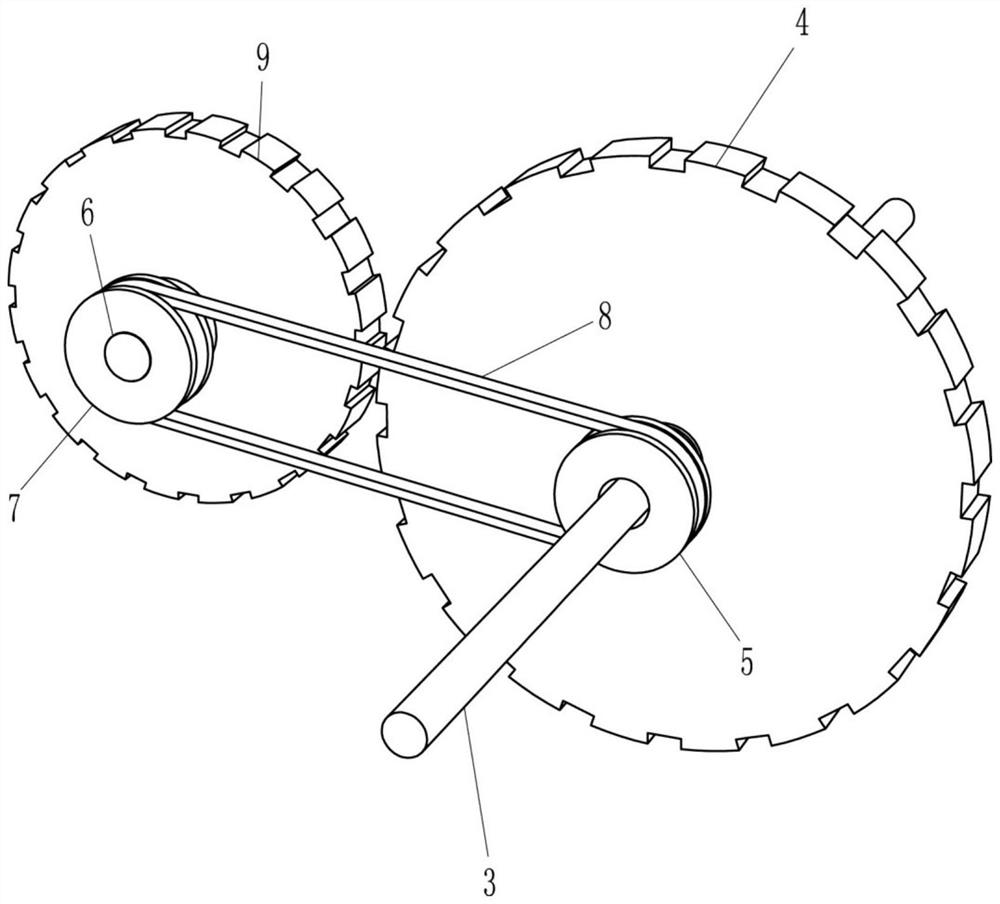

[0026] Such as figure 1 and 2 As shown, the slotting assembly includes a motor 2, a first rotating shaft 3, a first slotting wheel 4, a first pulley 5, a second shaft 6, a second pulley 7, a flat belt 8 and a second slotting wheel 9, and the installation The left part of the front side of the frame 1 is fixedly connected with a motor 2 by bolts, the output shaft of the motor 2 is connected with a first rot...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 7-8 As shown, in order to control the groove depth, it also includes a shaft sleeve 29, a slide bar 30, a third spring 31, a lifting plate 32, a fourth rotating shaft 33, a cam 34, a worm wheel 35, a worm screw 36 and a hand wheel 37, and the mounting frame 1 Both left and right parts are provided with axle sleeves 29, and the sliding type in the axle sleeves 29 is provided with a slide bar 30, a third spring 31 is connected between the slide bar 30 and the axle sleeve 29, and a lifting plate 32 is arranged between the slide bar 30 tops, The mounting frame 1 is rotatably provided with a fourth rotating shaft 33, the right part of the fourth rotating shaft 33 is key-connected with a cam 34, the cam 34 cooperates with the lifting plate 32, the left part of the fourth rotating shaft 33 is key-connected with a worm wheel 35, and the rear side of the mounting frame 1 passes through Bearing block rotation type is provided with worm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com