Radial bed isothermal reactor

A technology of isothermal reactor and radial bed, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of affecting the service life of equipment, increasing the difficulty of equipment manufacturing, and increasing equipment investment, so as to reduce equipment manufacturing. Difficulty, thinning equipment investment, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

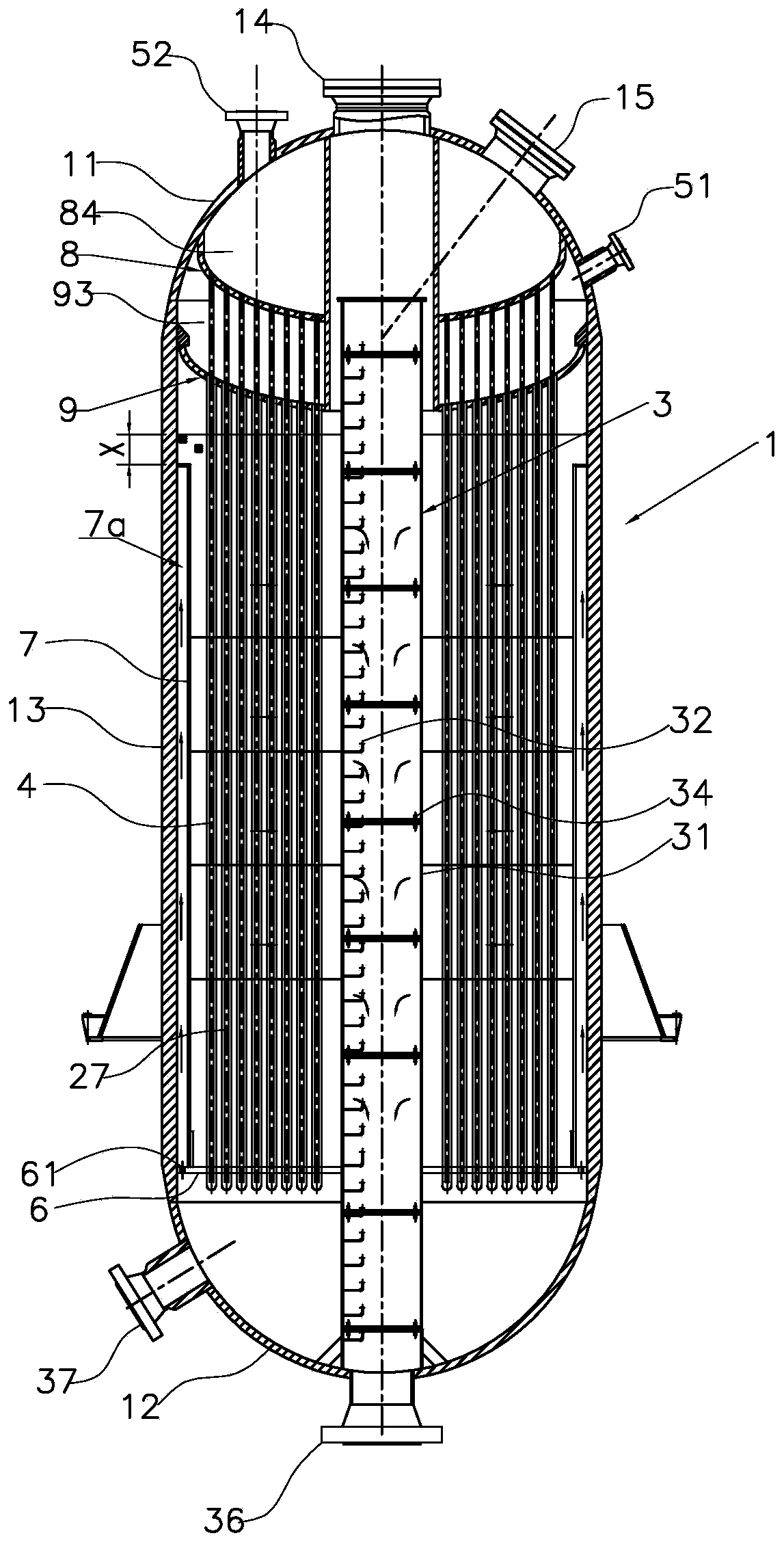

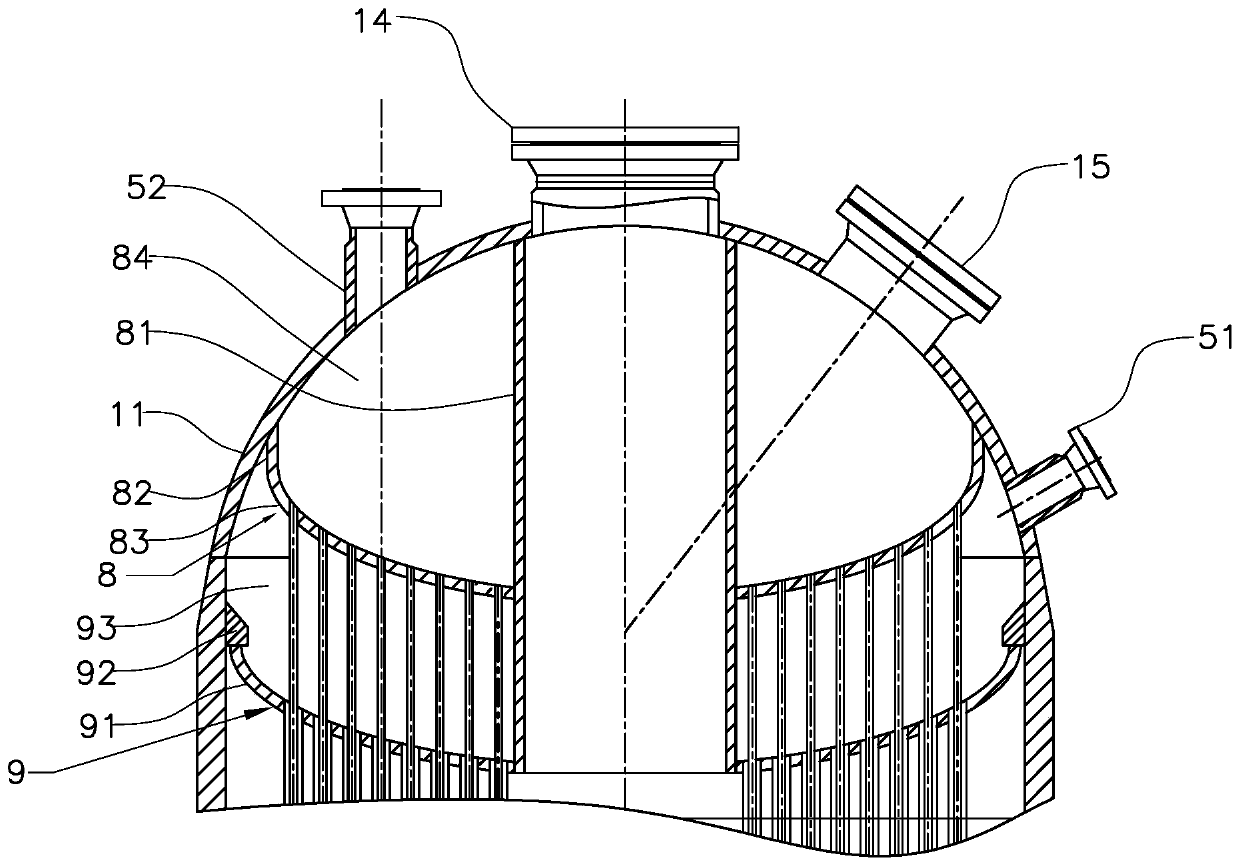

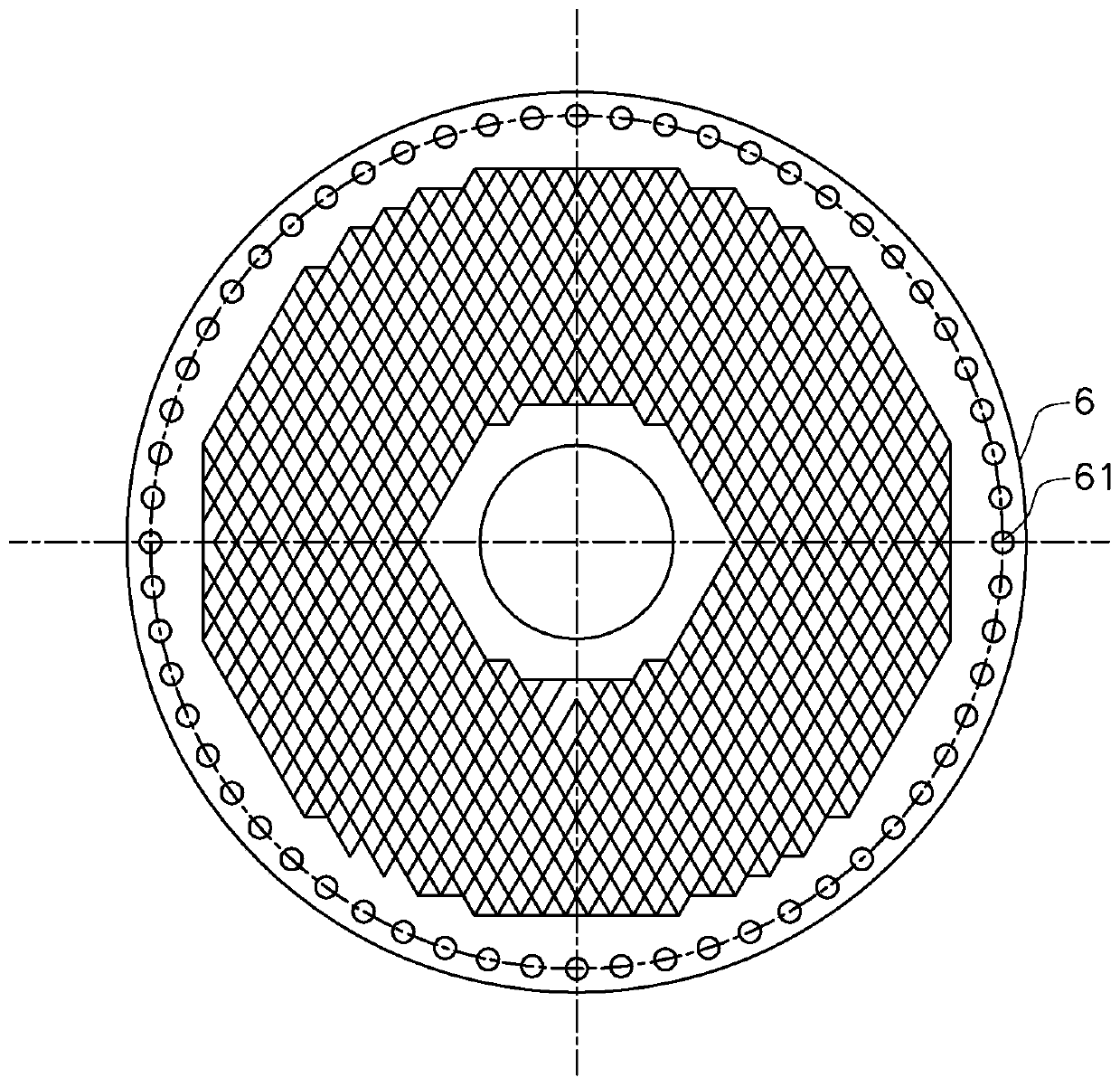

[0042] like Figure 1 to Figure 6 As shown, the new radial bed isothermal reactor includes: a furnace body 1, a lower tube plate 6, a heat exchange tube 4, a catalyst frame 7, a shift gas collection pipe 3, an upper tube plate 8, and a middle tube plate 9.

[0043] The upper tube sheet, the middle tube sheet and the lower tube sheet are horizontally arranged in the furnace body from top to bottom, and the inner chamber of the furnace body is divided into an upper chamber, a steam chamber, a reaction chamber and a lower chamber sequentially from top to bottom.

[0044]The furnace body 1 is composed of an upper sealing head 11 , a lower sealing head 12 and a cylinder body 13 connected between the upper sealing head 11 and the lower sealing head 12 . The center of the upper head 11 is provided with a second manhole 14, and the second manhole 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com