Food processor

A technology for food processors and heating devices, which can be used in home appliances, applications, kitchen utensils, etc. It can solve the problems of electrical component leakage, steam ingress, foam splashing, etc., achieve long cooking time, solve safety hazards, and prevent Splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

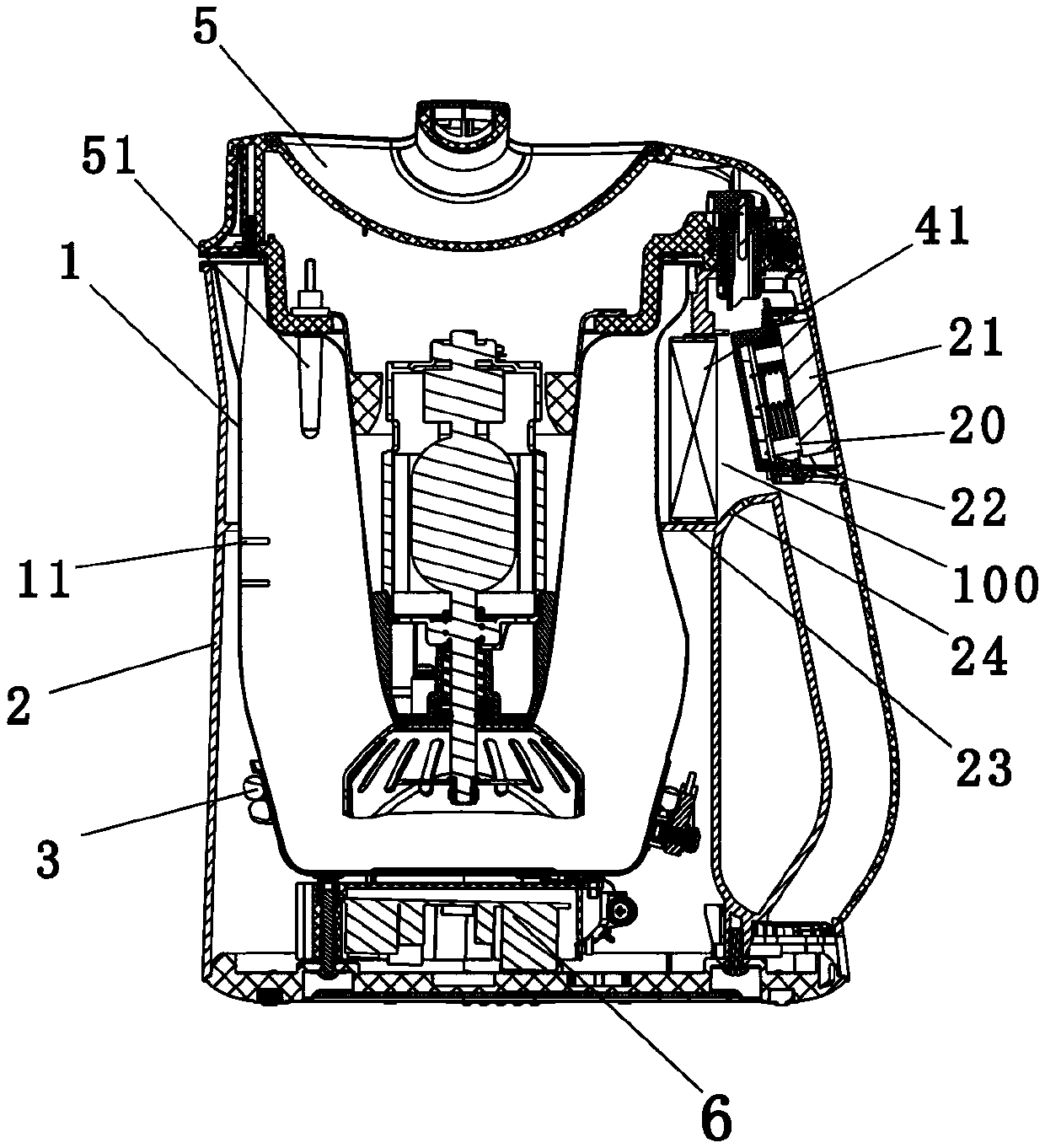

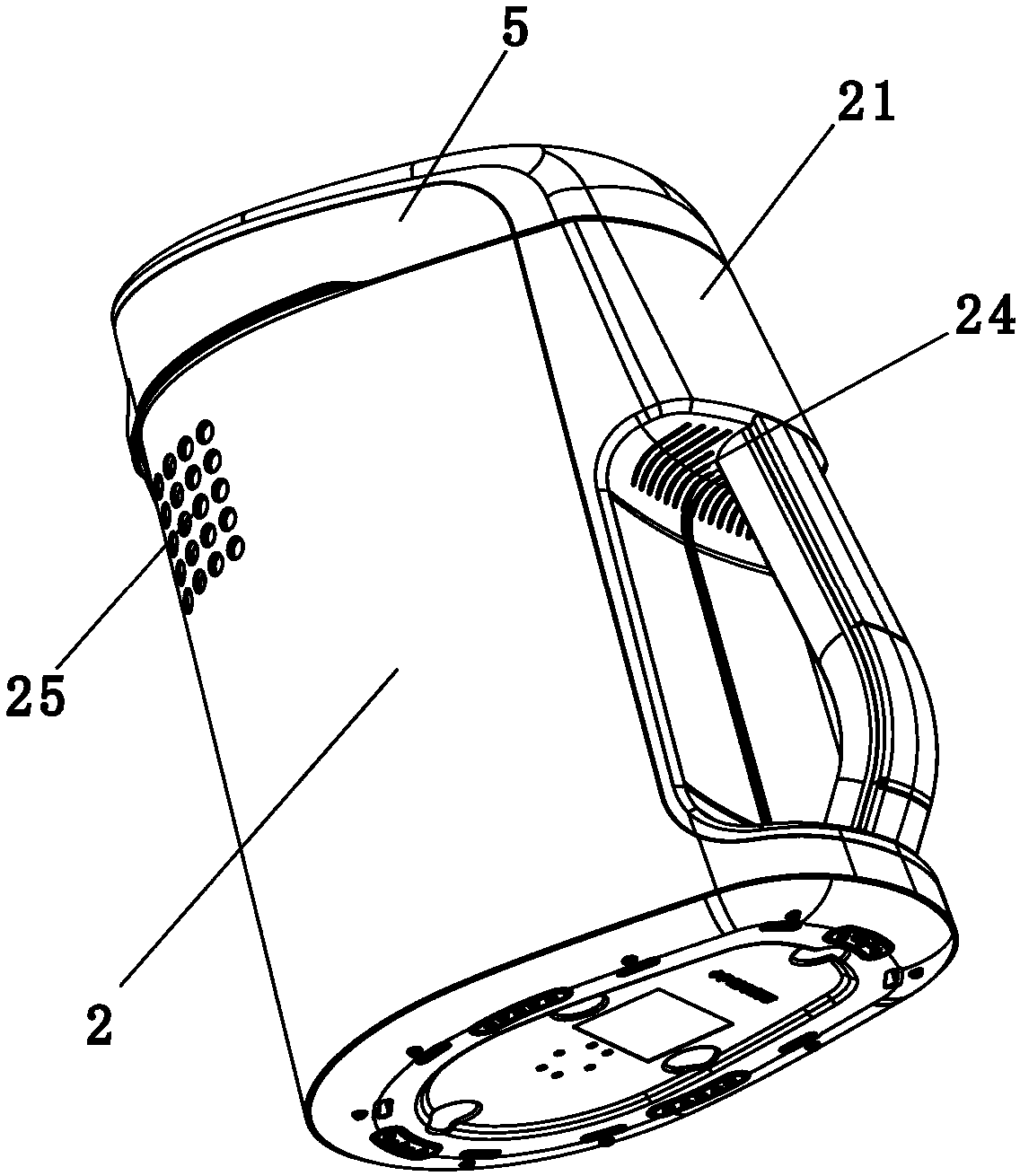

[0032] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A food processing machine, comprising an inner cup 1, a housing 2 arranged outside the inner cup and a heating device 3 for heating the inner cup 1, the inner cup 1 is provided with a water level mark 11, the housing 2 and the A cooling device is provided between the interlayers of the inner cup 1 , wherein, during the heating process of the heating device 3 , the cooling device cools the outer wall of the inner cup 1 above the water level mark 11 .

[0033] In this embodiment, the food processor is a soybean milk machine, the inner cup 1 is a metal cup body, the heating device 3 is fixed on the heating tube on the bottom side wall of the metal cup body, and the casing 2 is a metal cup body The cup body shell is located above the metal cup body and is also provided with a machine head 5. The machine head 5 is provided with an overflow detection pole 5...

Embodiment 2

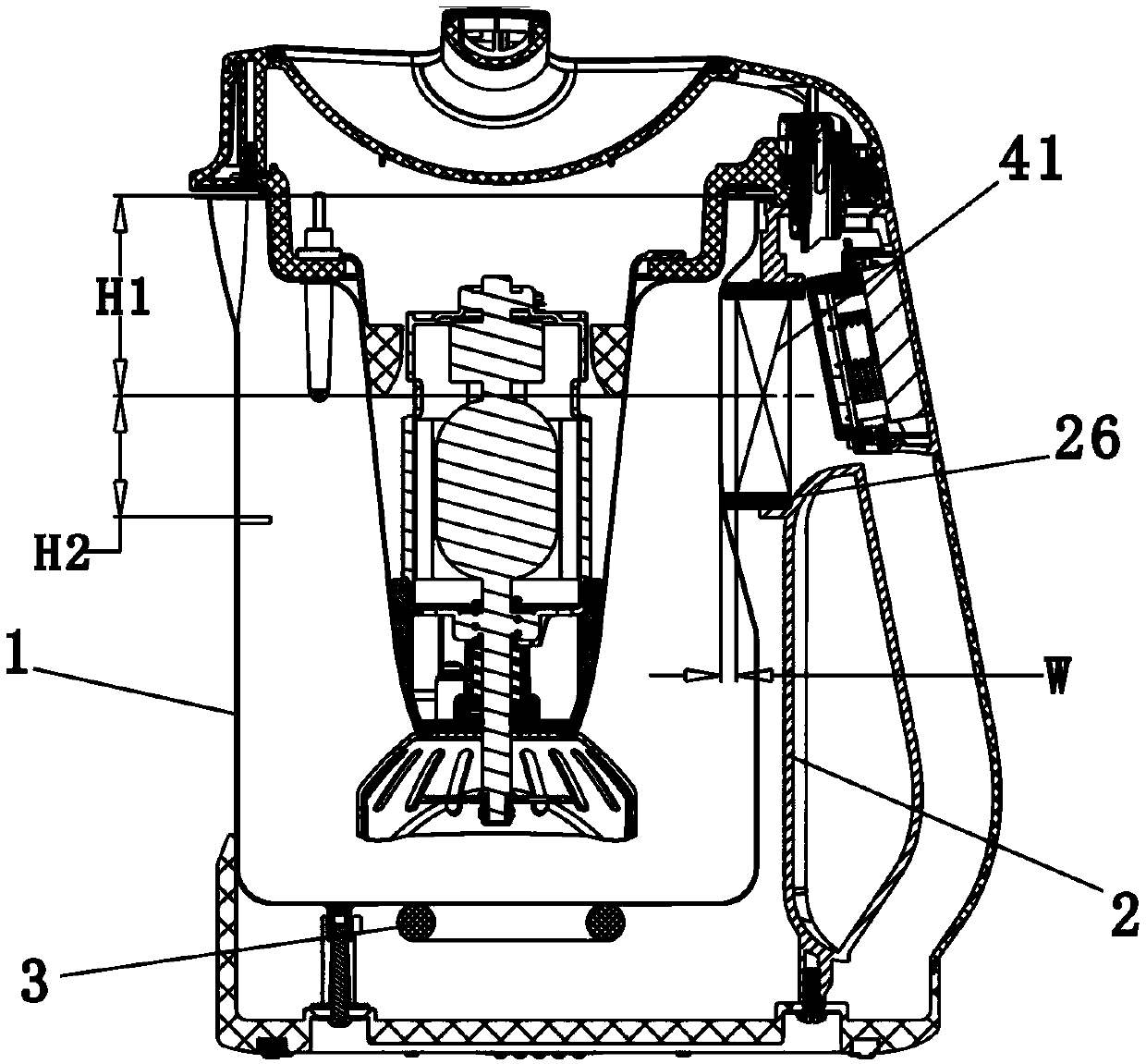

[0041] Such as image 3 , Figure 4 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that in this embodiment, the inner cup 1 is an exposed single-layer metal cup body, and the bottom of the metal cup body is provided with a heating device 3, and the casing 2 is made of metal A mounting plate extending from the upper end of the cup body to the lower end. There is an air outlet gap (not shown in the figure) between the mounting plate and the metal cup body. The interlayer enclosure forms a circulating cooling channel.

[0042] In this embodiment, a shock absorber 26 is arranged between the fan 41 and the mounting plate to isolate the fan 41 from the mounting plate, so as to prevent the vibration of the fan 41 from being transmitted to the mounting plate during operation, thereby causing the soybean milk machine to vibrate. Meanwhile, in this embodiment, one end of the shock a...

Embodiment 3

[0047] Such as Figure 5 Shown is a schematic structural view of the third embodiment of the present invention. A food processing machine, comprising a machine base 7, a cup body arranged on the machine base 7, the cup body includes an inner cup 1 and a housing 2 arranged outside the inner cup 1, the mouth of the cup body is provided There is a cup cover 8, there is no anti-overflow detection pole on the cup cover 8, the inner cup 1 is a metal cup body, and the bottom of the inner cup 1 is provided with a heating device 3, and the interlayer between the inner cup 1 and the shell 2 A control device 6 and a cooling device 4 are arranged between them, and the heating device 3 and the cooling device 4 are electrically connected to the control device 6 respectively, wherein the cooling device 4 includes a cooling fin 42 that is closely attached to the outer wall of the inner cup 1 and a pair of The heat sink 42 is a fan 41 for blowing and cooling. The fan 41 is installed on the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com