Combinable socket

A combined, socket technology, applied in the field of electricity, can solve the problems of waste of resources, difficult to select the size of the socket, etc., and achieve the effect of preventing electric shock and rusting of contact points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

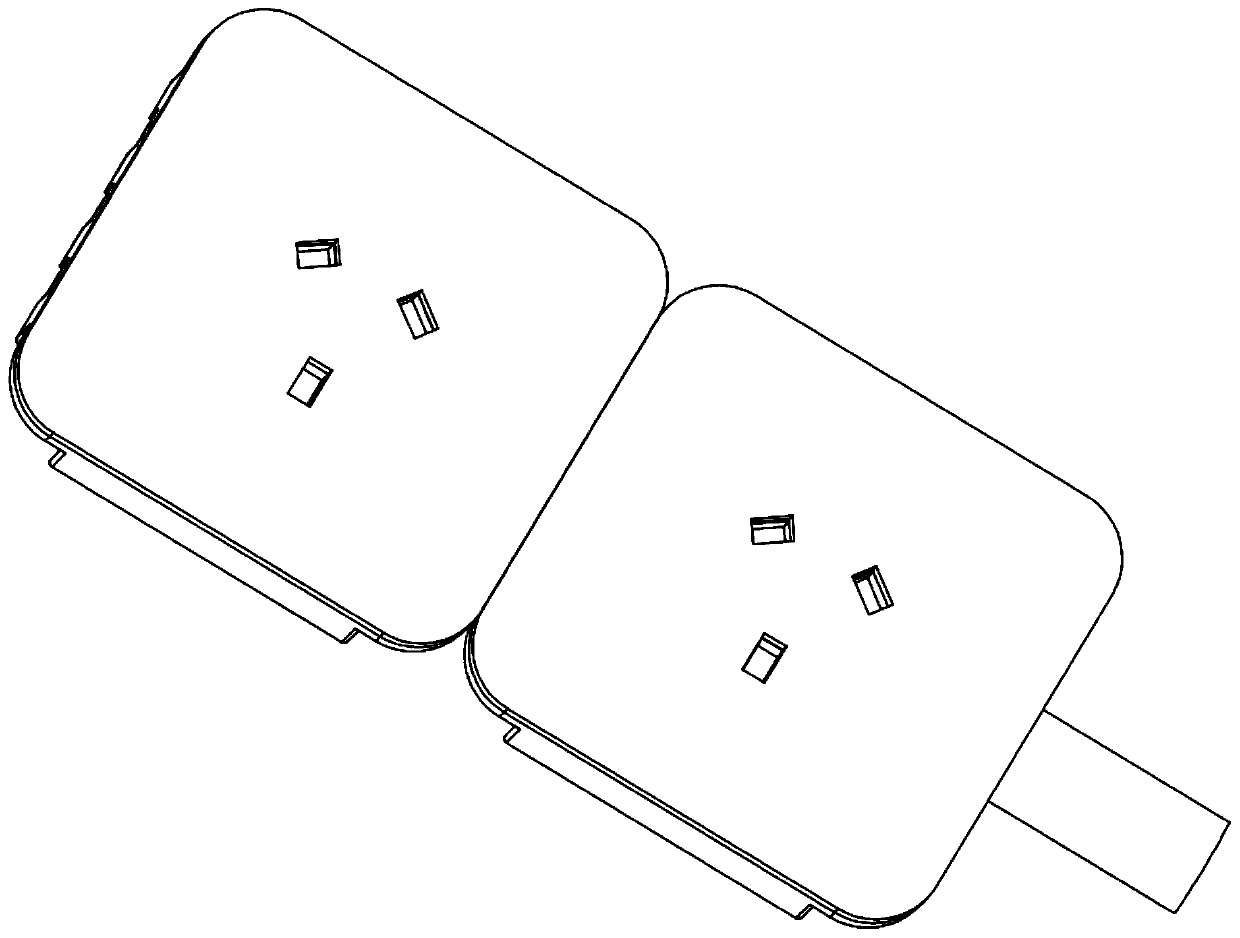

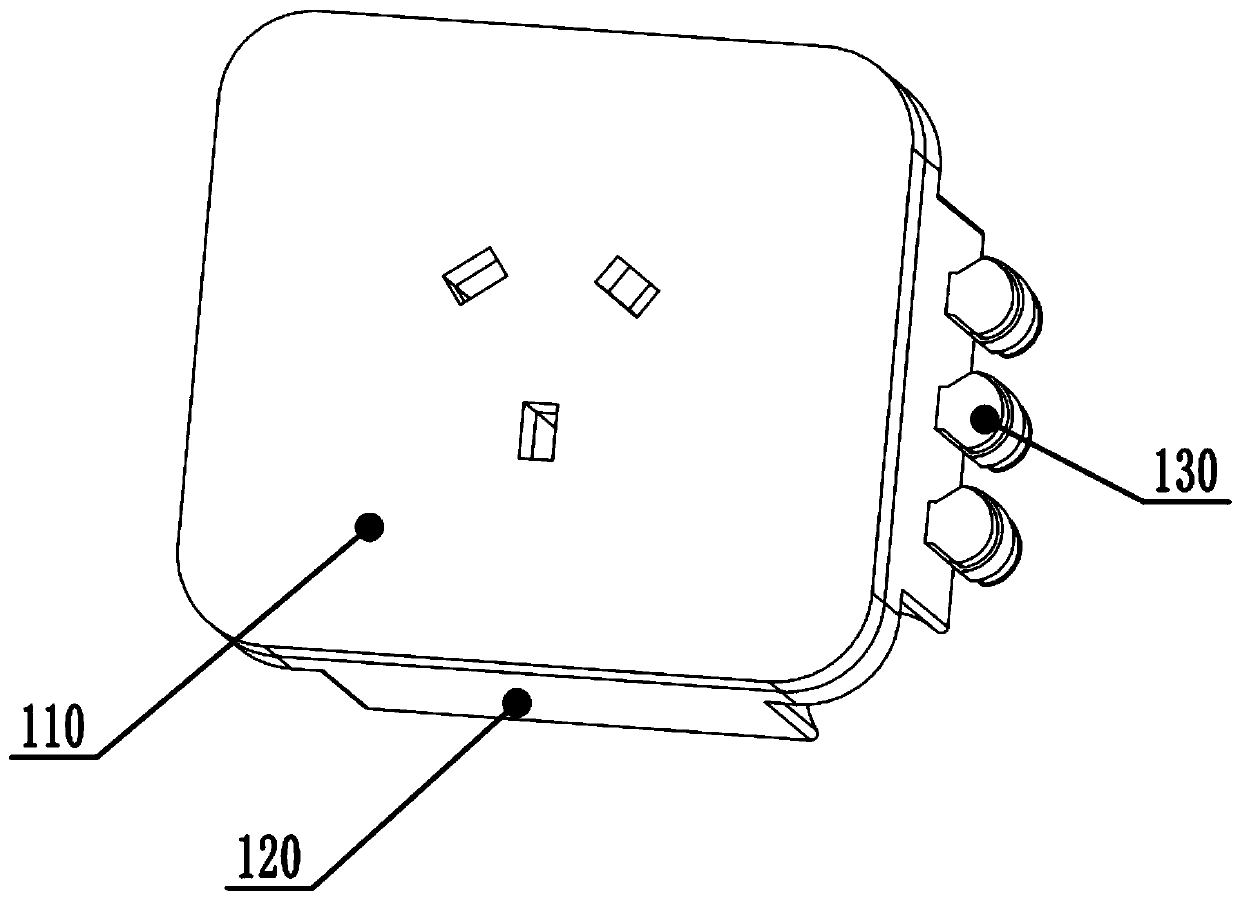

[0028] Specific embodiment one, please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown is a combinable socket, socket cover 110, socket box 120 and combined connection mechanism; it is characterized in that: the combined connection mechanism includes a protruding combination part and a concave combination part, and the combination through the protruding Parts and recessed combination parts are connected to realize the combination of multiple sockets to meet the needs of different socket numbers. Specifically, through the combination of multiple sockets, the combination of multiple sockets is realized. The contact points of the combined parts are contacted to realize electrification. The socket box 120 includes a jack portion 121 and a socket box bottom 122. The socket box bottom 122 is arranged on the socket box 120, and the jack portion 121 and the socket box bottom 122 are fixed by screws. .

[0029] Further, the combined...

specific Embodiment 2

[0034] In the second embodiment, the socket cover 110 and the socket box 120 are the same as in the first embodiment, the combined connection mechanism includes a protruding combined part B230 and a concave combined part B240; the protruding combined part B230 includes a protruding Pillar B231, the concave combination part B240 includes a combined groove B241, when combined, the protruding post B231 is inserted into the combined groove B241, specifically the shape of the protruding post B231 is the same as that of the combined groove B241, and the combined groove B241 is more convex than The post B231 is bigger, so that the protruding post B231 can be installed in the combination groove B241.

[0035] Further, the above-mentioned protruding post B231 is provided with an electric hole, and a contact post 242 is provided in the combined groove B241. When assembling, the circuit is connected by inserting the contact post 242 into the electric hole above the protruding post B231 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com