Compound absorption refrigeration unit

An absorption refrigeration and composite technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem that the heat exchange area of the evaporator and absorber cannot be fully utilized, the utilization of large temperature differences cannot be realized, and the needs of users cannot be met and other problems, to achieve the effect of reducing equipment investment, saving equipment space, and reducing steam driving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Aiming at the technical problem of the relatively low utilization rate of the heat exchange area of the evaporator and the absorber in the prior art, this paper conducts in-depth research, and proposes a technical solution to solve the above technical problem on the basis of the research, specifically Described as follows.

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

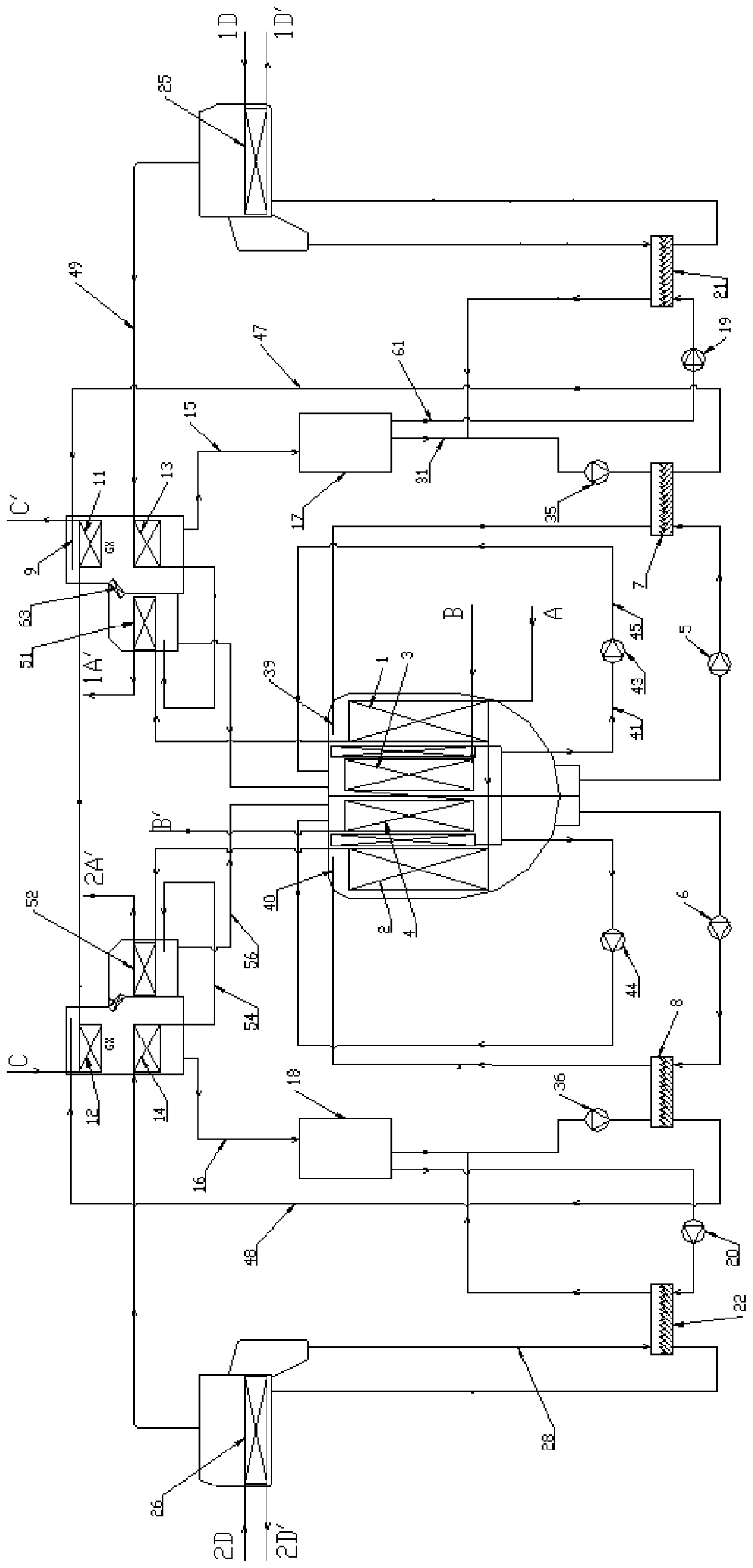

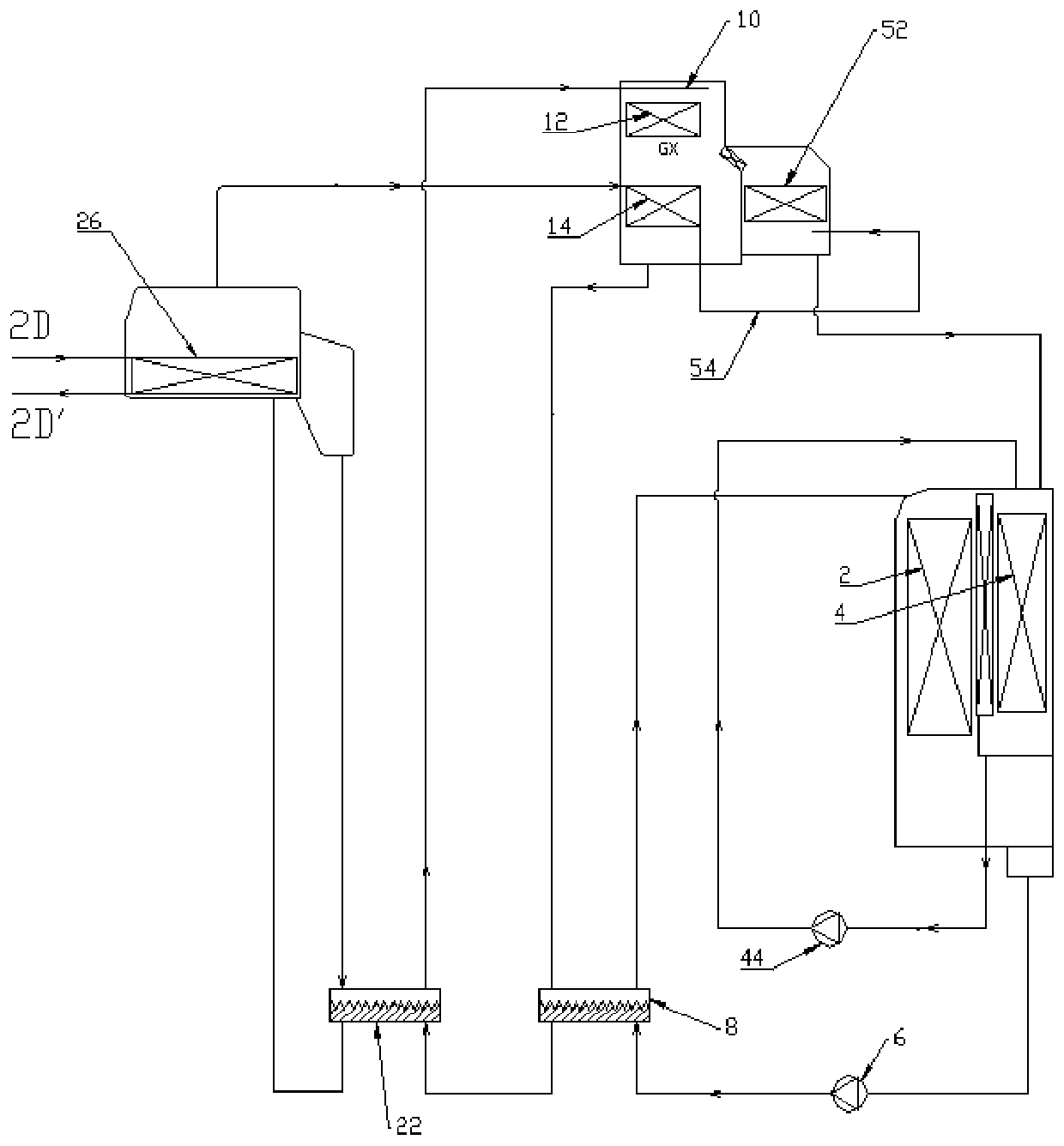

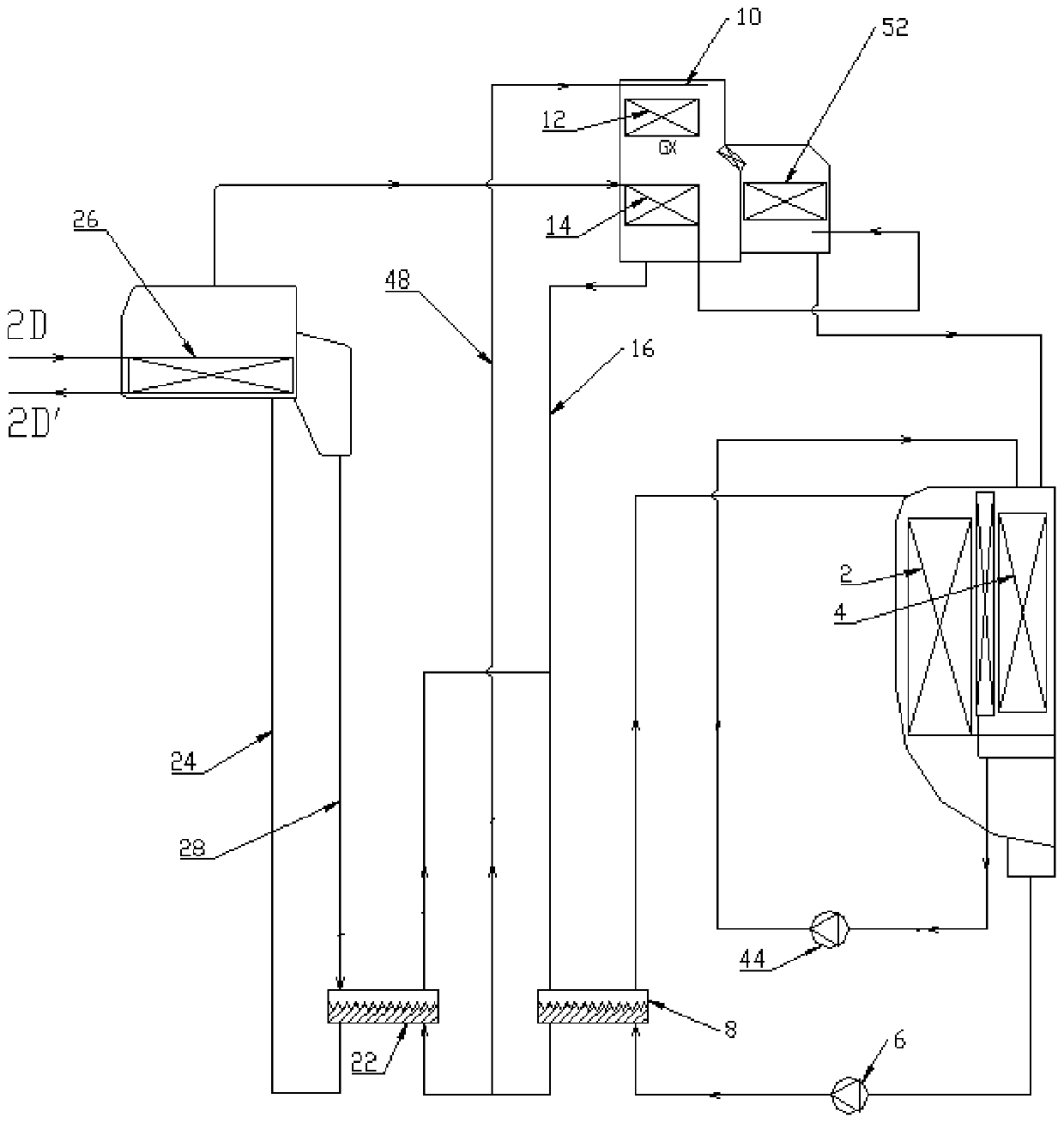

[0026] Please refer to Figure 1 to Figure 3 , figure 1 It is a structural schematic diagram of a composite absorption refrigeration unit in a specific embodiment of the present invention; figure 2 It is a structural schematic diagram of the modular unit series solution circulation loop in an embodiment of the present invention; image 3 It is a structural schematic diagram of a modular u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com