Ammonia-process desulfurization process and device

An ammonia-based desulfurization and process technology, which is applied in the field of calcination, can solve the problems of low desulfurization efficiency, high concentration, and desulfurization technology that cannot meet national standards, and achieve the effect of improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

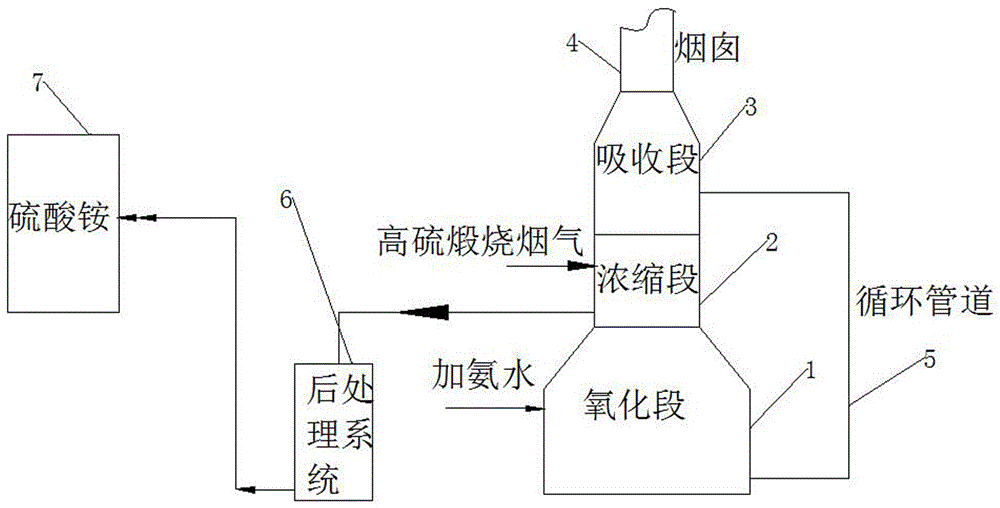

[0026] Embodiment, an ammonia desulfurization process, comprising the following steps:

[0027] a. High-sulfur calcined flue gas is passed into ammonia water, and the temperature of high-sulfur calcined flue gas is controlled at about 110°C when it enters the desulfurization tower, which plays a good role in controlling ammonia escape. It reacts with aqueous ammonia solution, and ammonia water removes SO in the flue gas 2 Absorb, remove SO 2 , the standard flue gas is discharged from the chimney;

[0028] b. Ammonia and SO 2 The reaction obtains an aqueous solution of the desulfurization intermediate product ammonium sulfite or ammonium bisulfite;

[0029] c. Bubble compressed air into the desulfurization intermediate product to carry out the oxidation reaction of ammonium sulfite, and directly oxidize ammonium sulfite into ammonium sulfate solution;

[0030] d, the ammonium sulfate solution is concentrated to obtain ammonium sulfate slurry with a solid content of about 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com