Duplex layered cyclone and duplex layered multi-pipe dust remover thereof

A cyclone and duplex technology, applied in cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problems of large size, high resistance loss and high cost of dust collectors, improve dust removal efficiency, reduce The effect of small resistance loss and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

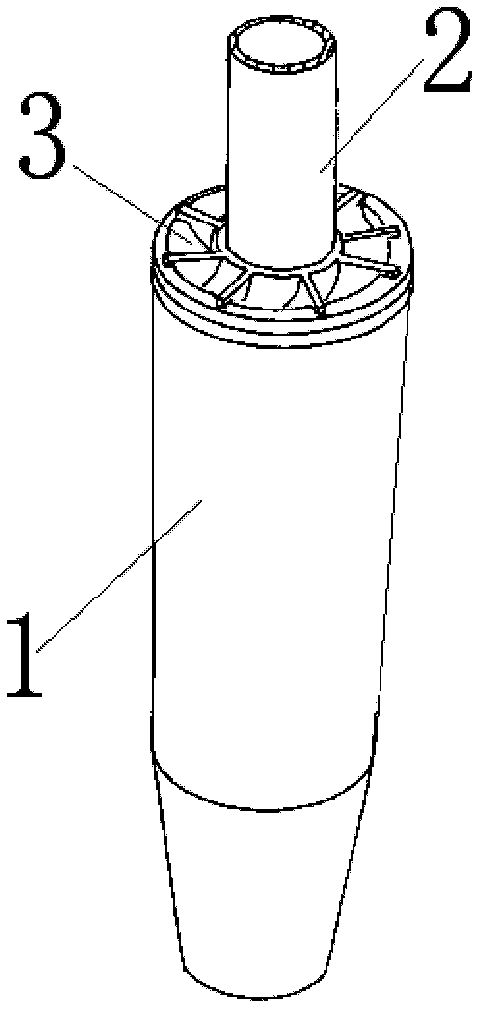

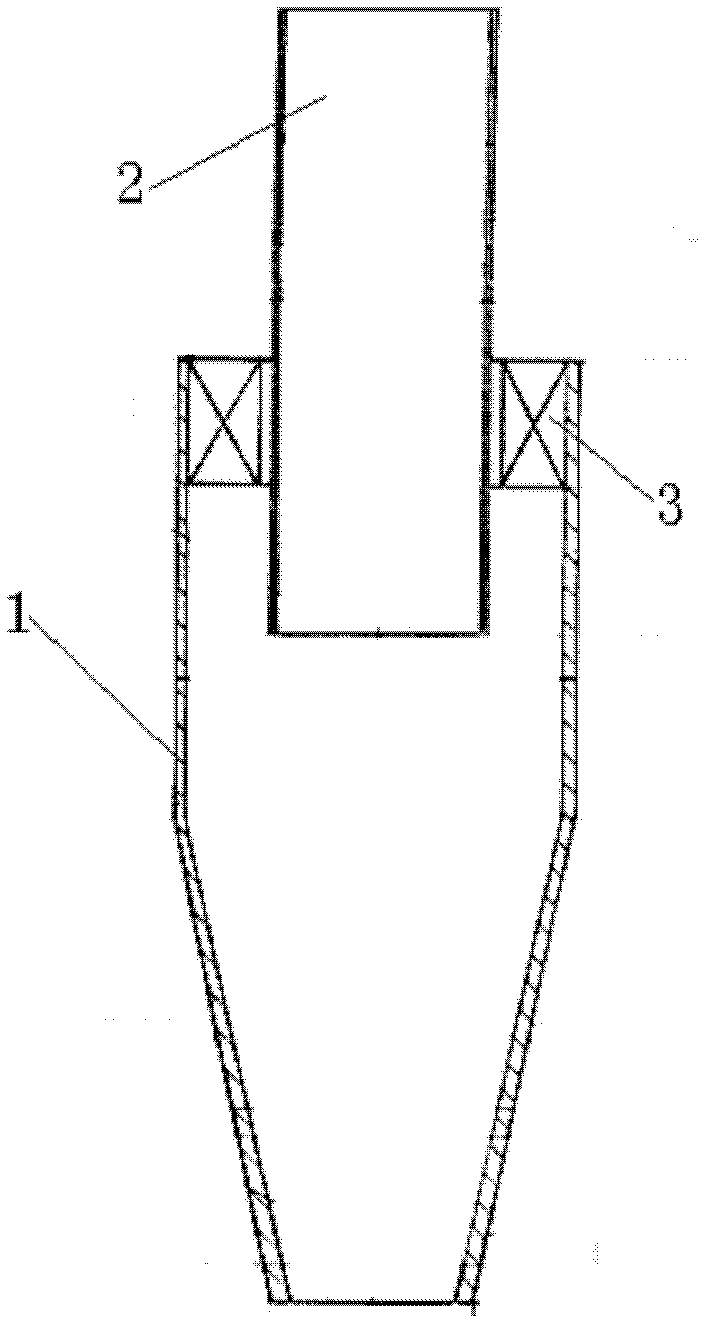

[0026] Cyclone in the prior art such as figure 1 As shown, it includes a swirl cylinder 1 and a centrifugal conduit 2, and the upper end of the swirl cylinder 1 is provided with a centrifugal guide vane 3, as figure 2 As shown, the centrifugal conduit 2 enters the interior of the cyclone cylinder 1 by being inserted into the through hole of the centrifugal guide vane 3 .

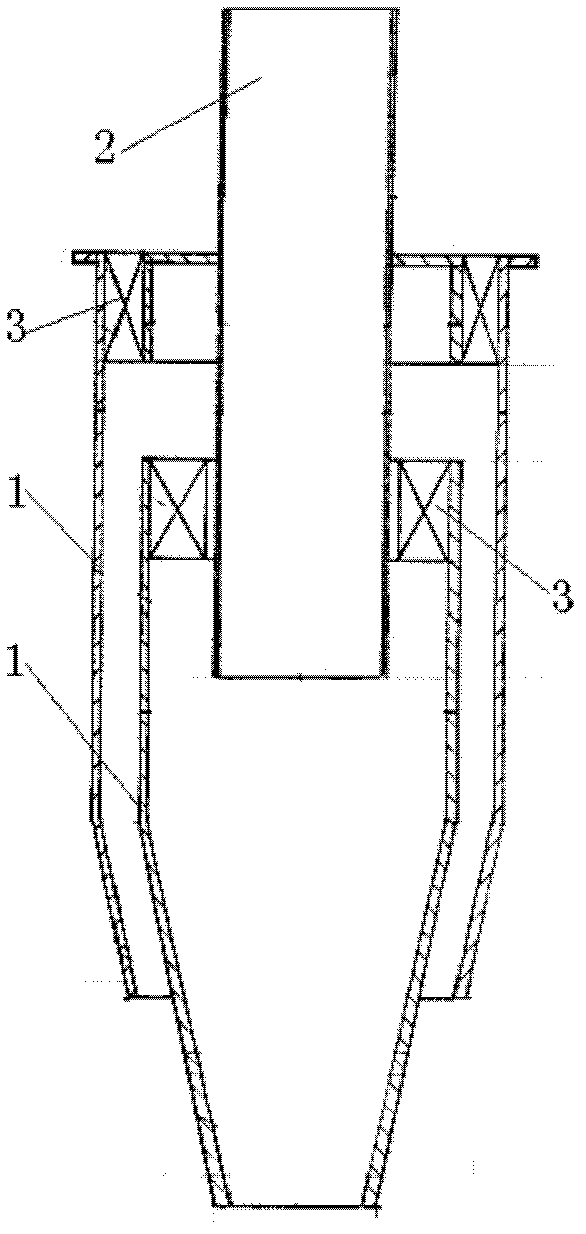

[0027] However, the design idea of the present invention is to design multiple swirl cylinders 1, and the multiple swirl cylinders 1 are distributed in a layered structure, that is, one swirl cylinder 1 is sleeved on another swirl cylinder 1. . A certain distance should be kept between the inner and outer cyclone cylinders 1 so that the outer surface of the inner cyclone cylinder 1 and the inner surface of the outer cyclone cylinder 1 form a space for dust and airflow to flow.

[0028] Centrifugal guide vanes 3 are arranged at the upper end port of each swirl cylinder 1, and the centrifugal guide vanes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com