Liquid pump and motor vehicle with a liquid pump

A technology for motor vehicles and liquid pumps, applied in liquid fuel engines, parts of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as increased wear and tear, and achieve the effect of reducing mechanical wear, compactness and maintenance-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

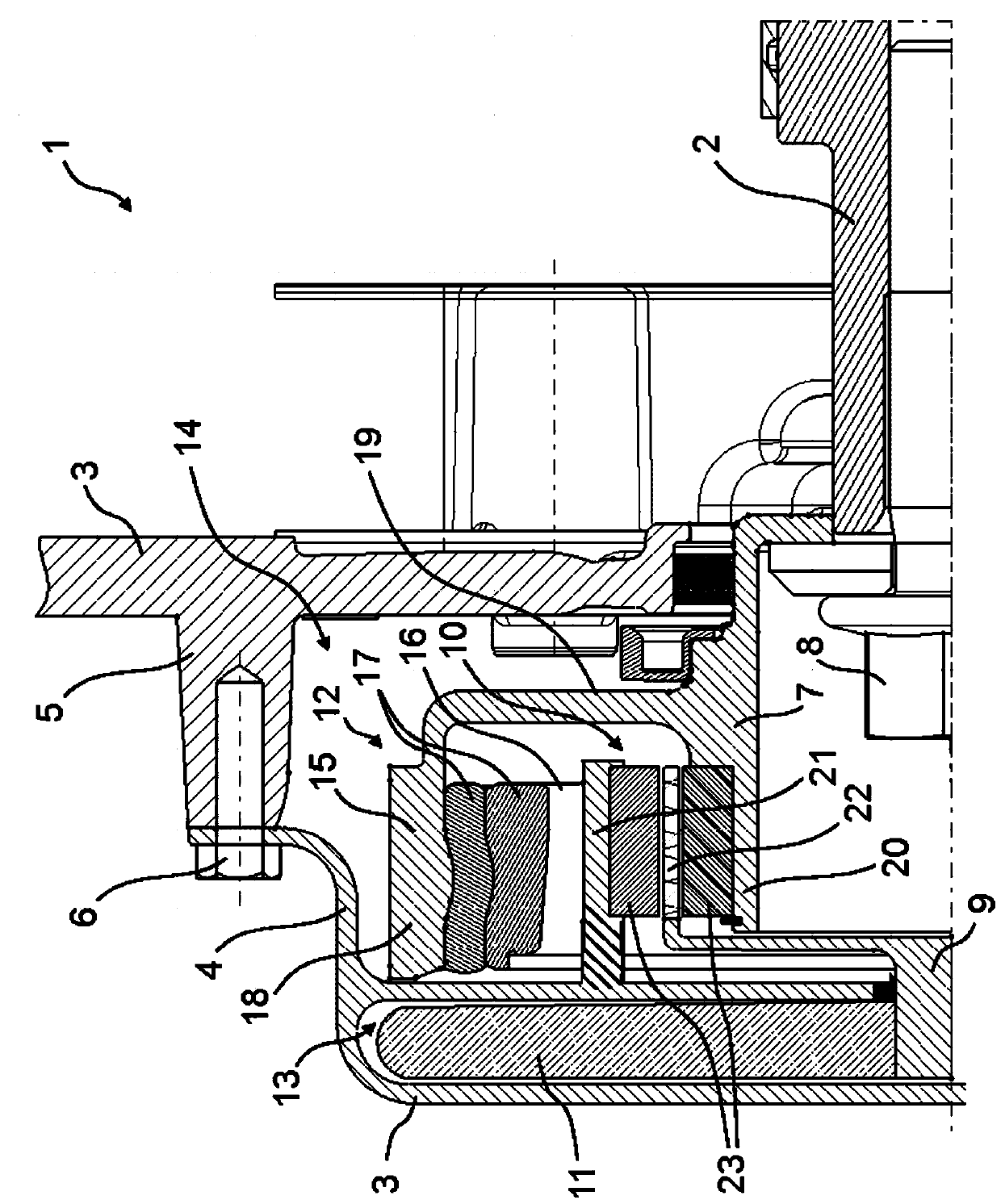

[0031] figure 1 A partial longitudinal section (in the present case upper half) of an exemplary embodiment of a liquid pump 1 for a motor vehicle according to the invention is shown schematically, not shown in detail. In the case of the illustrated exemplary embodiment, the liquid pump 1 is a water pump, and the motor vehicle including the liquid pump 1 is a hybrid vehicle. In addition to an electric motor, not shown, the hybrid vehicle also has an internal combustion engine (not shown), which drives the crankshaft 2 . from figure 1 As can be clearly seen in , the crankshaft 2 of the internal combustion engine is directly and rigidly connected to the pump 1 in order to drive it, as will be explained in more detail below.

[0032] from figure 1 It can also be seen in the figure that the pump 1 has a two-part housing 3 which in turn has a detachable cover 4 which can be removed, for example via figure 1 The screw arrangement 6 visible in is fastened to the housing plate 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com