Grounding nail

A grounding nail and ground drilling technology, which is applied in the field of grounding nails, can solve the problems of inconvenient construction and maintenance, discounted effect, and infirmity, so as to increase electrical conductivity and corrosion resistance, save time and effort to tighten and disassemble, and increase electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

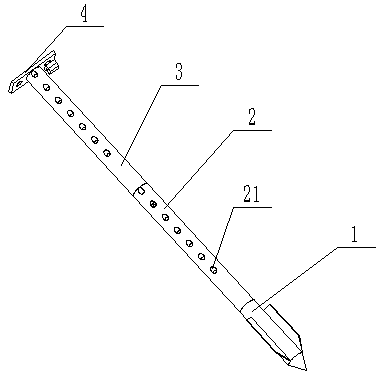

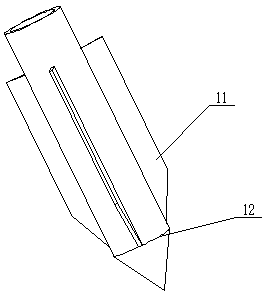

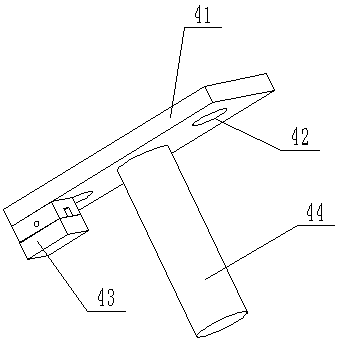

[0049] According to attached figure 1 , attached Figure 4 , attached Figure 5 And attached Figure 7 A grounding nail is shown, including a ground-drilling guide head 1, a base rod 2 detachably connected with the ground-drilling head guide head 1, and a striking device 4 detachably connected with the base rod 2; the ground-drilling guide The head 1 includes a drill body 12 and blades 11 evenly distributed on the outer surface of the drill body 12; the ground-drilling guide head 1, the basic rod 2 and the striking device 4 are sequentially connected. The ground-drilling guide head 1 is tapered as a whole with a blade 11, and the base rod 2 is a hollow structure; the detachable connections are threaded connections. The beating device 4 includes a beating plate 41, a joint 44 arranged on the lower surface of the beating plate 41, and a clamping device 43 arranged on one side of the joint 44; two ends of the beating plate 41 are provided with Lifting hole 42; Described snap-...

Embodiment 2

[0053] According to attached figure 1 , attached Figure 4 , attached Figure 5 And attached Figure 7 A grounding nail is shown, including a ground-drilling guide head 1, a base rod 2 detachably connected with the ground-drilling head guide head 1, and a striking device 4 detachably connected with the base rod 2; the ground-drilling guide The head 1 includes a drill body 12 and blades 11 evenly distributed on the outer surface of the drill body 12; the ground-drilling guide head 1, the basic rod 2 and the striking device 4 are sequentially connected. The ground-drilling guide head 1 is tapered as a whole and has a blade 11, and the base rod 2 is a hollow structure; the detachable connection relationship is a threaded connection; the hitting device 4 includes a hitting plate 41, which is arranged on the hitting plate The joint 44 on the lower surface of 41 and the clamping device 43 arranged on one side of the joint 44; the two ends of the striking plate 41 are provided wit...

Embodiment 3

[0057] According to attached figure 1 , attached Figure 4 And attached Figure 7 A grounding nail is shown, including a ground-drilling guide head 1, a base rod 2 detachably connected with the ground-drilling head guide head 1, and a striking device 4 detachably connected with the base rod 2; the ground-drilling guide The head 1 includes a drill body 12 and blades 11 evenly distributed on the outer surface of the drill body 12; the ground-boring guide head 1, the base rod 2 and the striking device 4 are sequentially connected; the base rod 2 and the growth Water holes 21 are all arranged on the pipe 3; the water holes 21 are upward oblique holes; The clamping device 43 on one side of the joint 44; the two ends of the striking plate 41 are provided with lifting holes; the clamping device 43 includes an upper locking piece 421, a lower locking piece 422 that is engaged with the upper locking piece 421 and For fixing the latch 423 of the upper latch 421 and the lower latch 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com