Blade sentencing

A technology of blades and components, which is applied in the field of judging blades used in turbine engines, can solve problems such as waste, and achieve the effect of improving judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

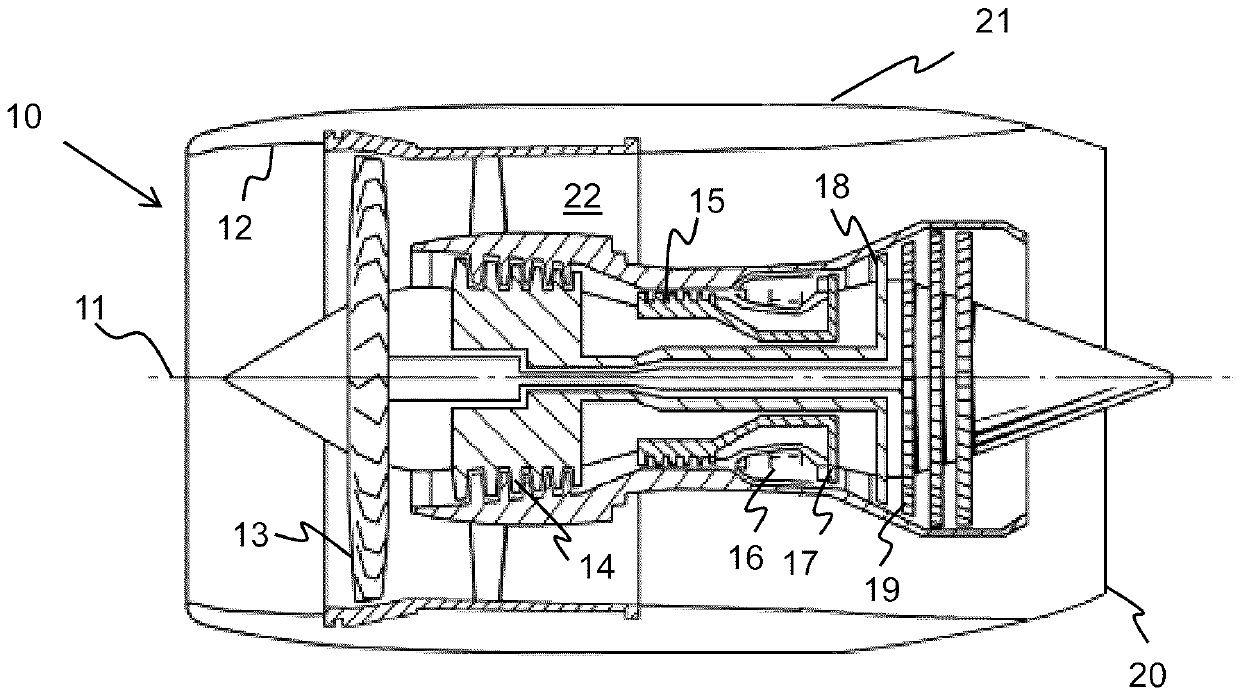

[0027] according to figure 2 , a gas turbine engine generally indicated at 10 having a main and rotational axis 11 . Engine 10 includes air inlet 12 , propulsion fan 13 , medium pressure compressor 14 , high pressure compressor 15 , combustion equipment 16 , high pressure turbine 17 , medium pressure turbine 18 , low pressure turbine 19 and exhaust nozzle 20 in axial flow sequence. The compartment 21 generally surrounds the engine 10 and defines both the inlet 12 and the exhaust nozzle 20 .

[0028] The gas turbine engine 10 operates in a conventional manner whereby air entering the inlet 12 is accelerated by the fan 13 to generate two air streams: a first air stream into the intermediate pressure compressor 14 and a bypass passage 22 to provide propulsion thrust the second air flow. The medium-pressure compressor 14 compresses the air flow introduced into it before passing it to the high-pressure compressor 15 where further compression takes place.

[0029] The compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com