A Tunable Polymer Microvial Based Ethanol Gas Sensor

A gas sensor and polymer technology, applied in the field of sensing, can solve problems such as inability to guarantee uniformity, complicated operation, and gas concentration measurement error, and achieve the effects of avoiding the reduction of gas concentration sensitivity, simple manufacturing process, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the specific structure, principle and working process of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

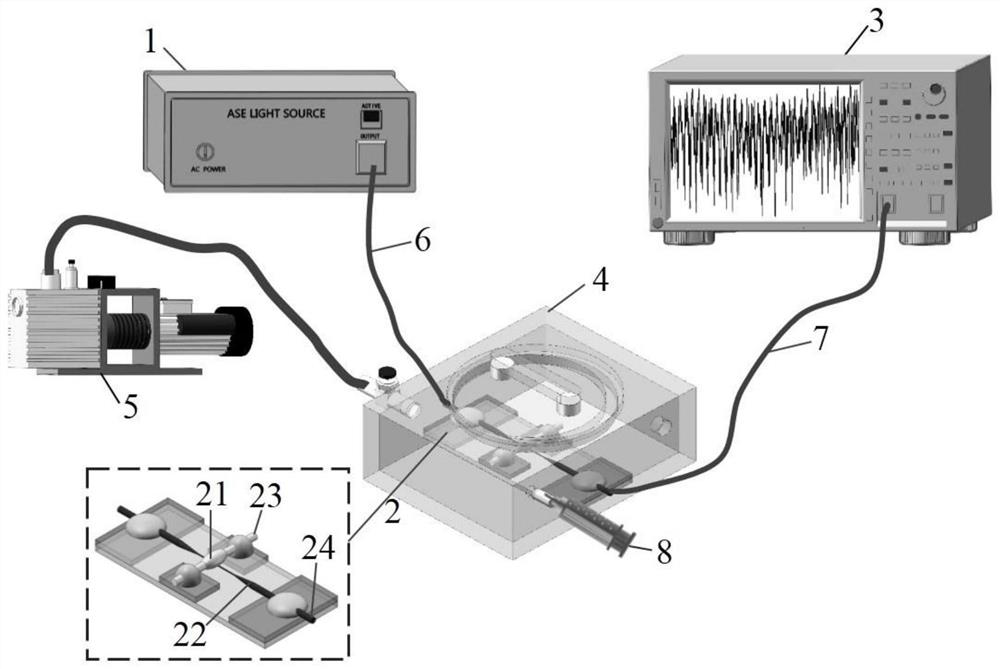

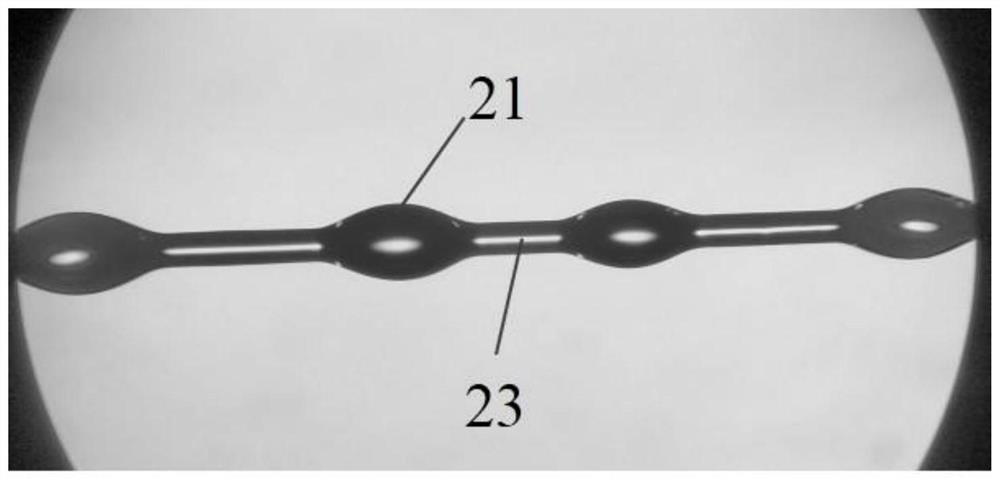

[0028] Such as figure 1 Shown is a transmissive optical fiber sensor for ethanol gas concentration measurement proposed by the present invention. Its working process is as follows: the light emitted by the wide-spectrum light source 1 is first transmitted to the micro-nano fiber 22 through the first single-mode fiber 6, and due to the evanescent field generated by the micro-nano fiber 22, the light is coupled into the tunable polymer microvial 21 and generated Due to the resonance effect, the light satisfying the resonance wavelength will be localized in the tunable polymer microvial 21, and the rest of the light enters the second single-mode fiber 7 through the mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com