Prefabricated trench groove fish nest component

A prefabricated assembly and fish nest technology, which is applied in fish farming, water conservancy projects, artificial waterways, etc., can solve the problems that fish cannot escape, and achieve the effects of protecting biodiversity, easy quality control, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

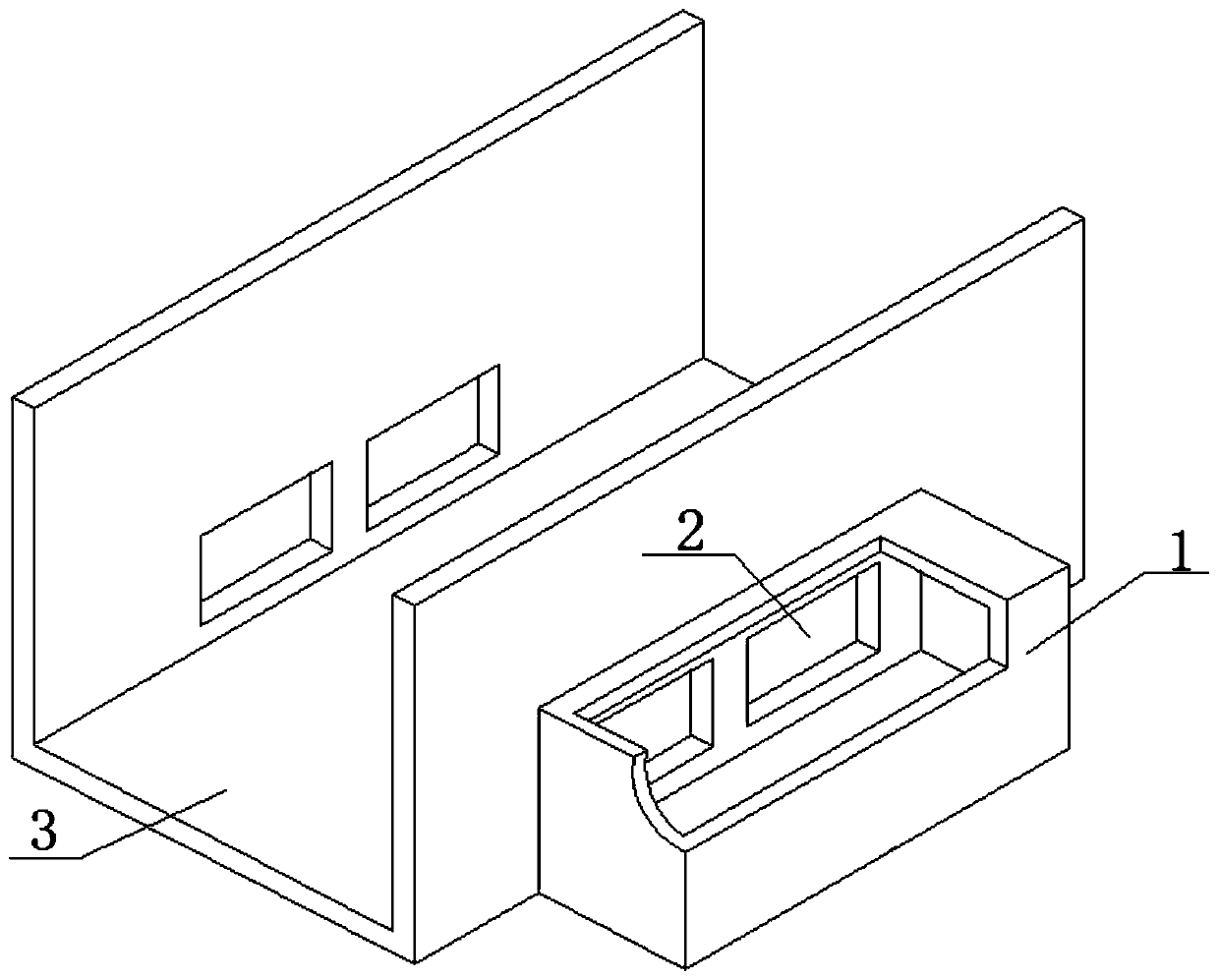

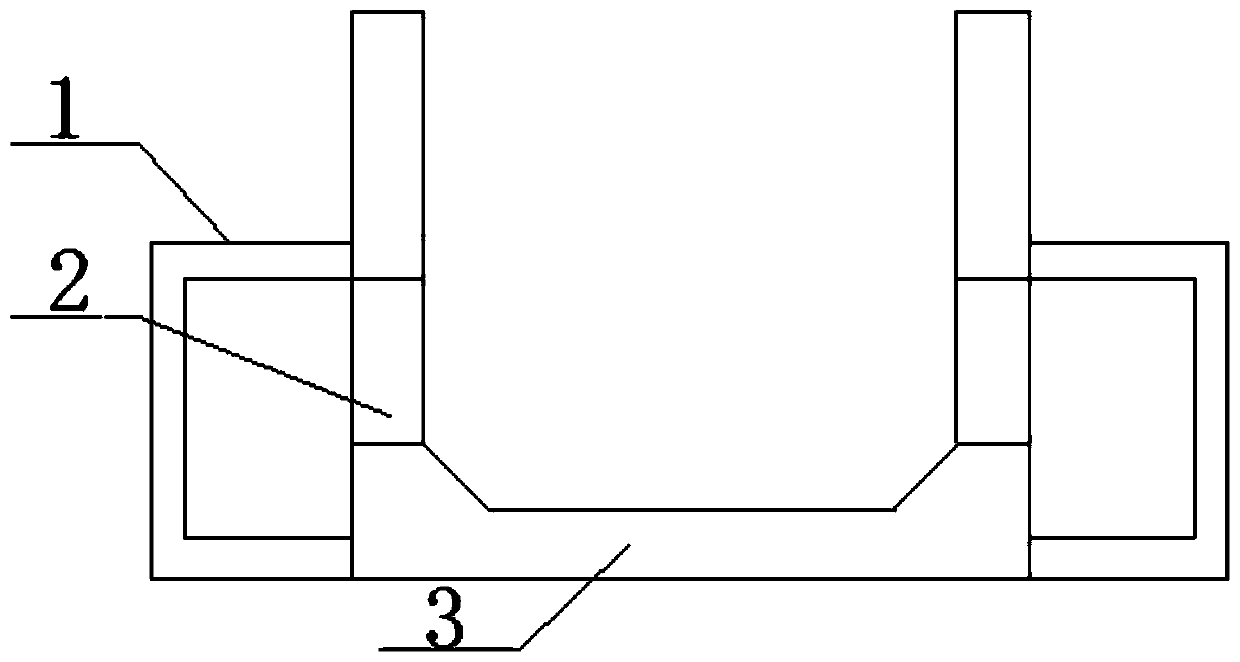

[0012] Specific implementation mode one: combine figure 1 and figure 2 As shown, the present embodiment is a prefabricated assembled channel fish nest component, which includes: a fish nest box 1, a fish nest entrance 2 and a prefabricated assembled channel 3; the fish nest entrance 2 is set in the fish nest box The rectangular opening structure on one side of the body 1; the two sides of the prefabricated channel 3 are provided with rectangular openings of the same size as the fish nest entrance and exit; the rectangular opening of the prefabricated assembly channel 3 communicates with the fish nest entrance 2 .

[0013] In this embodiment, the prefabricated channel 3 is communicated with the fish nest box 1 through a rectangular hole to construct a shelter for aquatic organisms such as fish.

[0014] In this embodiment, the prefabricated trench 3 is a rectangular irrigation and drainage canal, and the side walls and bottom of the trench are arranged vertically.

[0015] ...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the prefabricated trench 3 is a rectangular irrigation and drainage channel. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the connection between the rectangular opening of the prefabricated channel 3 and the fish nest entrance 2 is waterproofed. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com