Water seepage device and method

A technology of seepage pipes and seepage holes, which is applied to water supply devices, sewage discharge, waterway systems, etc., can solve the problems of inability to play the role of permeable concrete, high cost, and short service time, so as to alleviate urban waterlogging disasters, simple construction, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

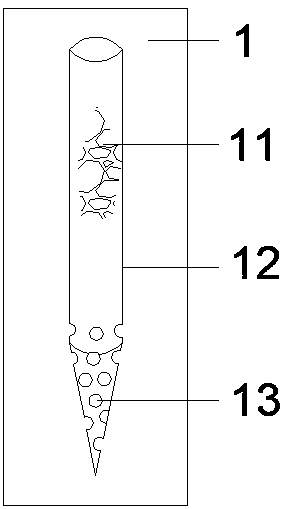

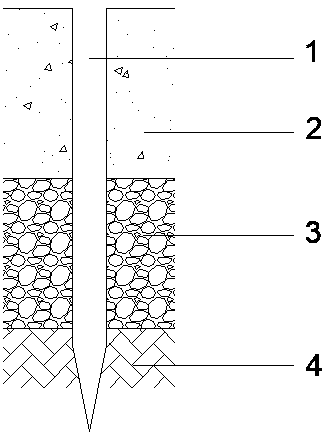

[0016] Such as figure 1 and figure 2 As shown, a water seepage device and method, including a water seepage device 1, the water seepage device 1 is placed in the (asphalt) concrete ground structure, and the (asphalt) concrete ground structure is soil foundation 4 and coarse sand cushion from bottom to top 3 and (asphalt) concrete layer 2. The upper part of the water seepage device 1 is flush with the upper surface of the (asphalt) concrete layer 2 , and the water seepage device 1 is composed of a water seepage material 11 , a water seepage pipe 12 and a water seepage hole 13 . The seepage material 11 is installed in the seepage pipe 12, one end of the seepage pipe 12 extends into the soil foundation 4 to a certain depth, and the part of the seepage pipe 12 extending into the soil foundation 4 has a water seepage hole 13, and the seepage pipe 12 extends into the soil foundation 4. One end of the foundation 4 is conical, and the water seepage material 11 is preferably fine-gr...

Embodiment 2

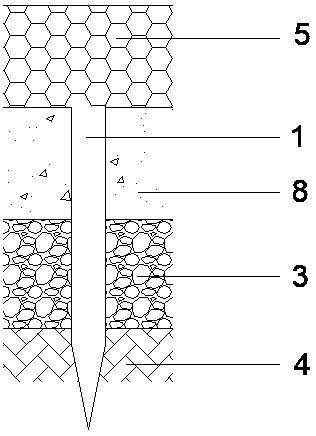

[0018] This embodiment is the application of this method in the permeable concrete ground structure, specific reference image 3 , The permeable concrete ground structure is the soil foundation 4, the coarse sand cushion 3, the concrete cushion 8 and the permeable concrete layer 5 from bottom to top. The water seepage device 1 passes through the concrete cushion 8, the upper part of the water seepage device 1 is flush with the upper surface of the concrete cushion 8 and the lower surface of the permeable concrete layer 5, and the lower part of the water seepage device 1 extends into the soil foundation 4 to a certain depth . The water seepage device 1 can be replaced by water permeable materials such as small stakes and straw ropes.

Embodiment 3

[0020] This embodiment is the application of this method in the permeable brick paved ground structure, specifically refer to Figure 4 , The permeable brick paving ground structure from bottom to top is soil foundation 4, coarse sand cushion 3, concrete cushion 8, fine sand cushion 7, and permeable brick layer 6. The water seepage device 1 passes through the concrete cushion 8 , the upper part of the water seepage device 1 is flush with the upper surface of the concrete cushion 8 and the lower surface of the fine sand cushion 7 , and the lower part of the water seepage device 1 extends into the soil foundation 4 . The water seepage device 1 can be replaced by water permeable materials such as small stakes and straw ropes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com