A kind of method for heat treatment of tungsten-rhenium alloy wire

A tungsten-rhenium alloy and alloy wire technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems affecting the physical properties of alloy wires, brittle fracture and splitting, etc., to improve brittle fracture resistance, eliminate residual stress, Effect of grain size refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

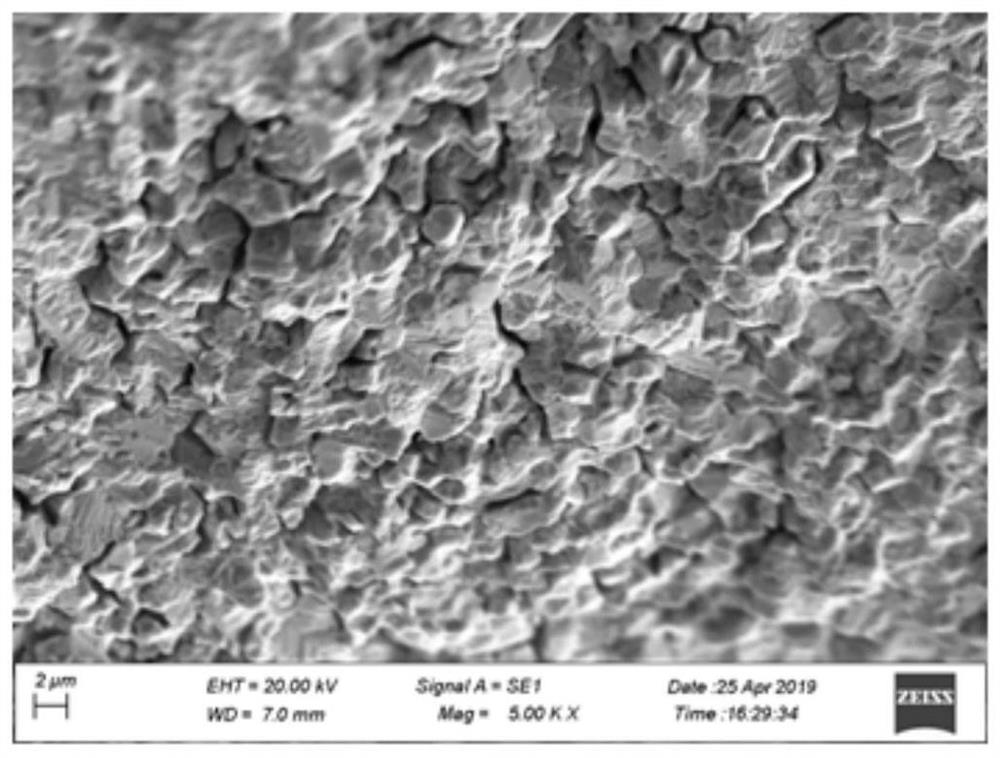

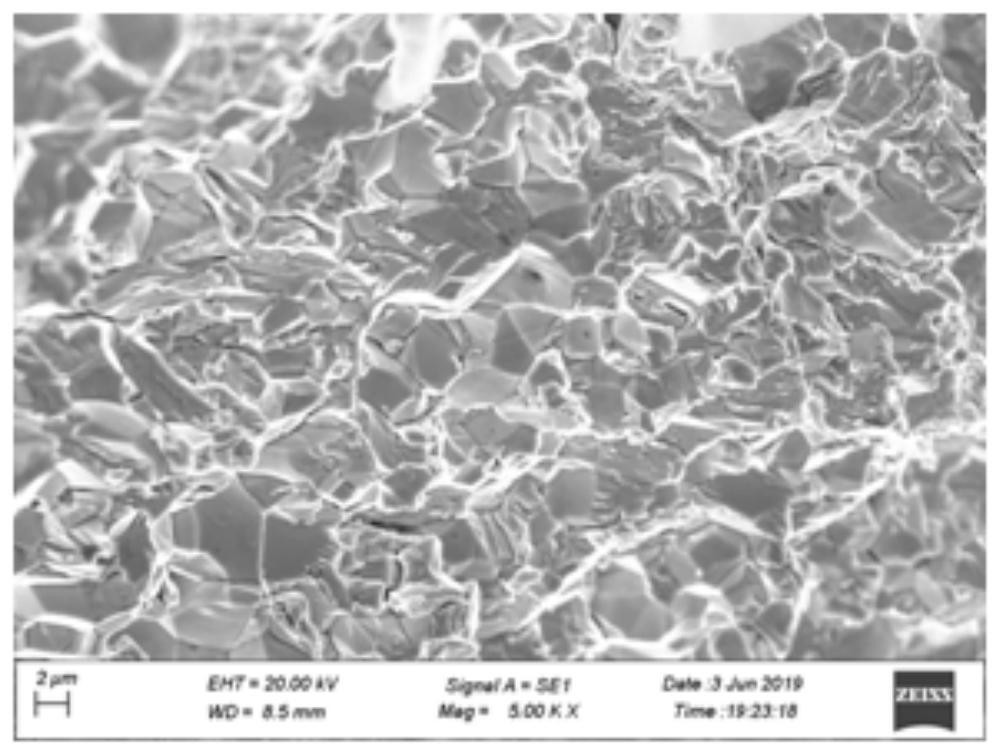

Image

Examples

Embodiment 1

[0053] Put the tungsten-rhenium couple wire with a length of 25cm into the quartz tube, the inner diameter of the quartz tube is 0.5cm, and the length is 110cm. After connecting the quartz tube with a rubber plug, put it into the corundum furnace tube of the silicon-molybdenum rod high-temperature furnace, and seal the joint Seal with raw tape. Argon gas is fed into the furnace bottom tube, the argon pressure is 0.35MPa, the flow rate is 0.5L / min, and the time is 5min. After 5 min, open the hydrogen gas valve. The pressure of hydrogen is 0.4MPa, and the flow rate is 50mL / min. Start the set program and turn on the heating power. When the furnace temperature reaches 1200°C, increase the flow rate of hydrogen to 80mL / min, hold the temperature for 1h, and then drop the temperature. When the temperature in the furnace drops below 300°C, adjust to cool with the furnace, stop feeding hydrogen, and continue feeding argon into the furnace for 5 minutes to drain the hydrogen and let ...

Embodiment 2

[0055] The process is the same as in Example 1, the heat treatment temperature is 1200° C., and the holding time is 2 hours. The measured bending strength reaches 3402.4 Mpa, and the bending strength increases by 5.34% after treatment.

Embodiment 3

[0057] The process is the same as in Example 1, the heat treatment temperature is 1300° C., and the holding time is 2 hours. The measured bending strength reaches 3514.9 Mpa, and the bending strength increases by 8.82% after treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com