Sewage precipitation and purification control method for sewage plant

A control method and technology of a sewage plant, which is applied in chemical instruments and methods, sedimentation treatment, water/sewage treatment, etc., can solve the problems of inconvenient internal cleaning, small amount of impurity precipitation, and insufficient uniformity of flocculant feeding and mixing, etc., to achieve improved purification Treatment effect, effect of convenient dredging treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

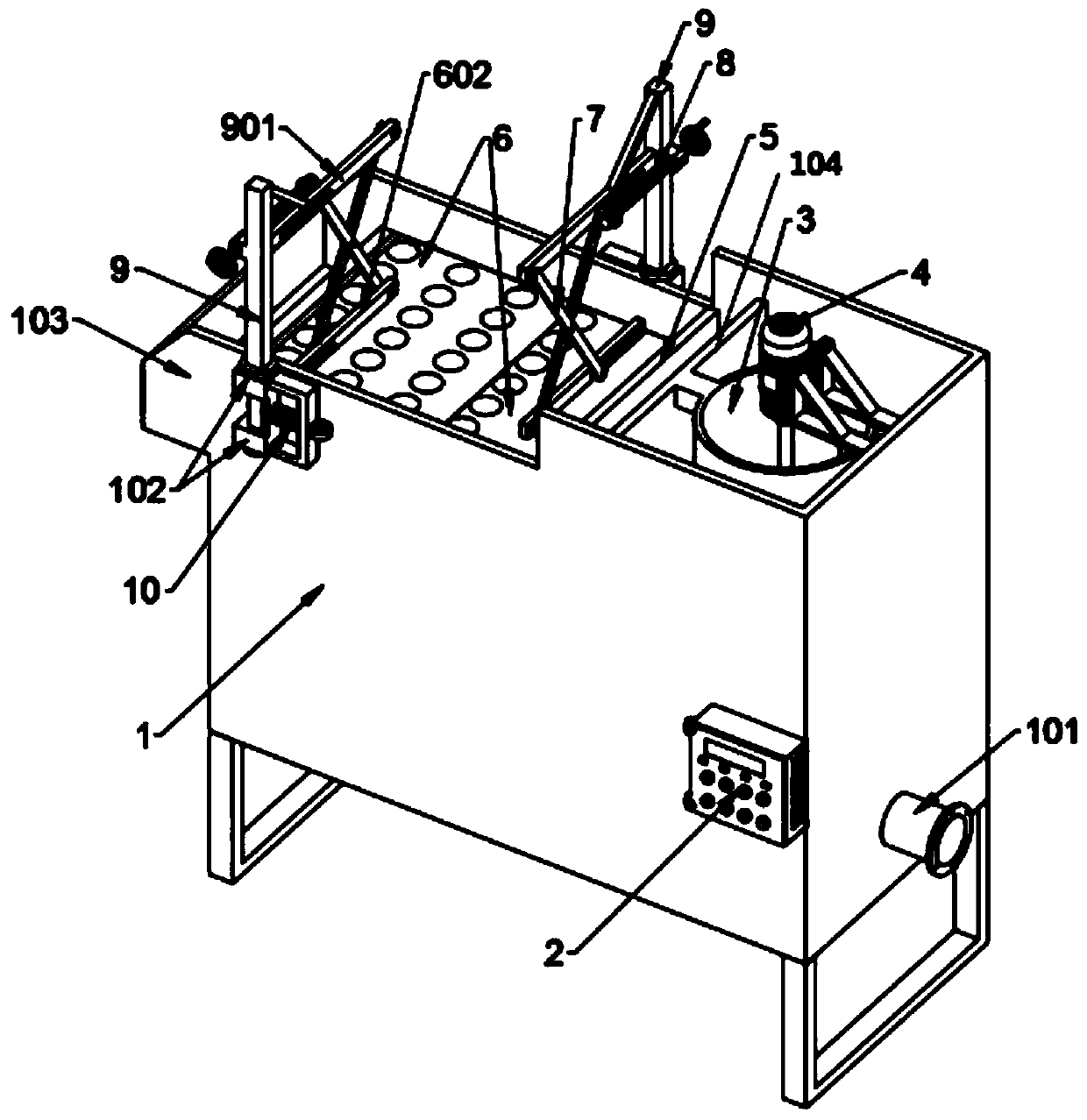

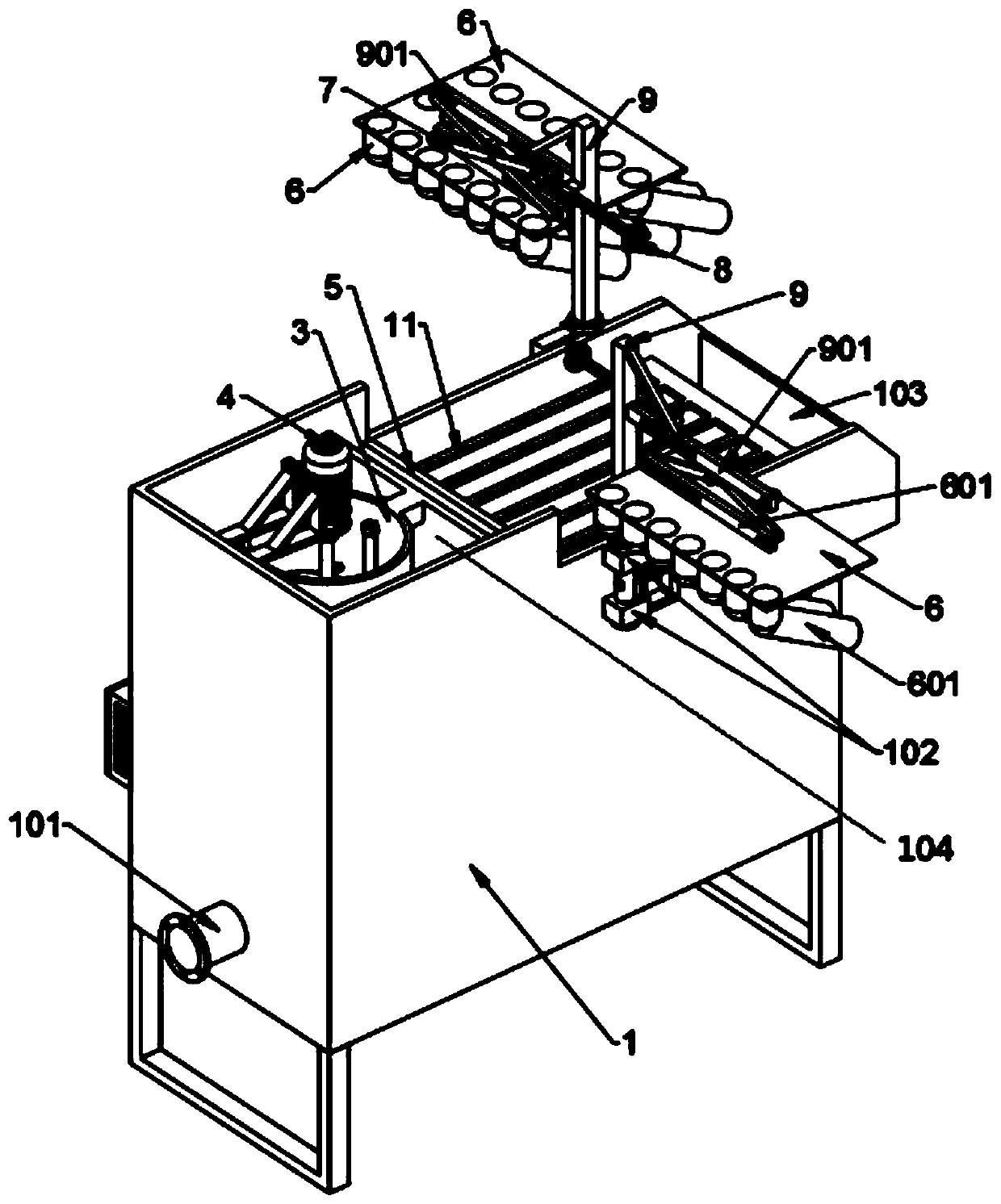

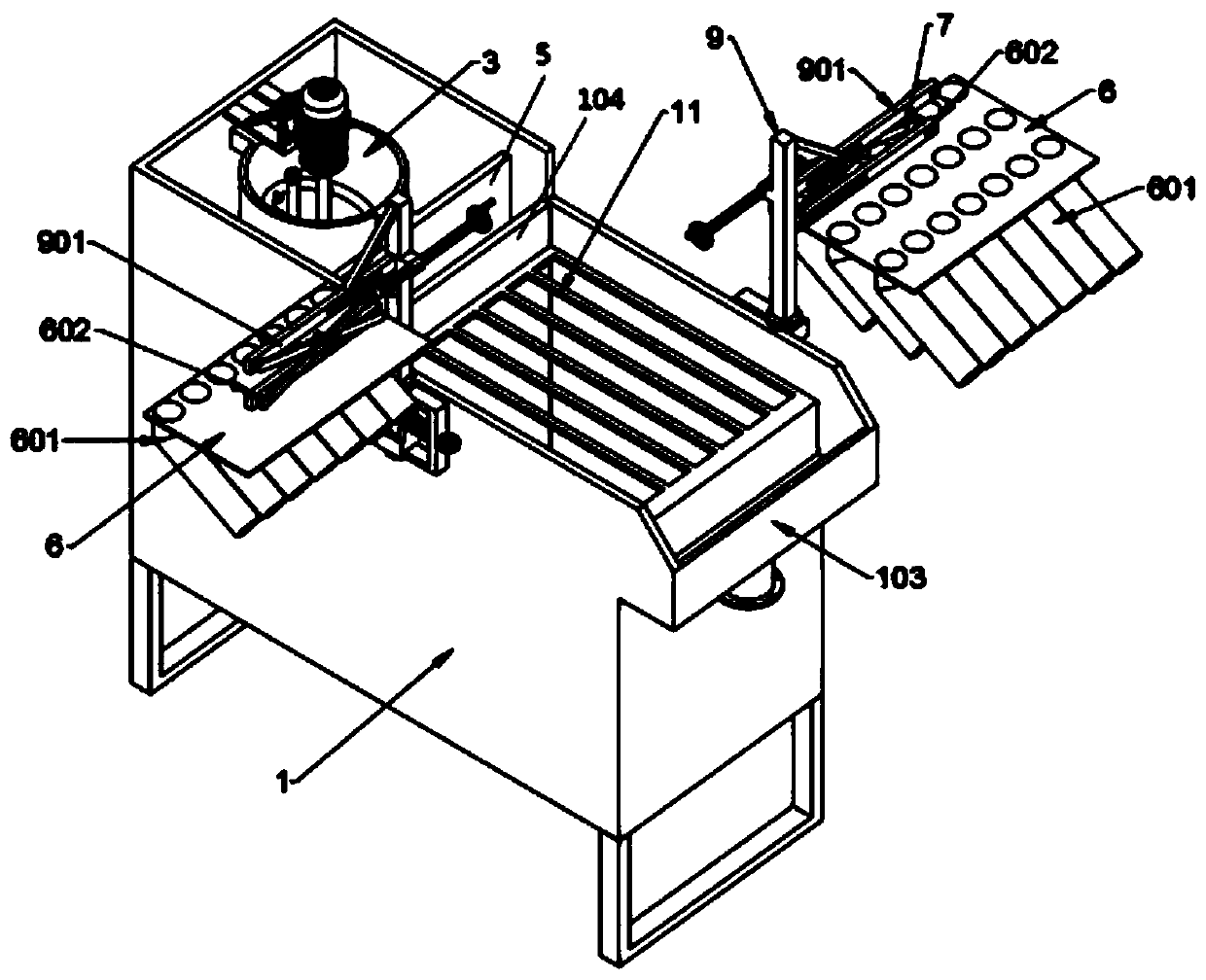

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a slanted plate and inclined tube sedimentation equipment used in a sewage plant, including a sedimentation tank 1, a water inlet pipe 101, a positioning block 102, an overflow tank 103, a first partition plate 104, a control electric box 2, and a flow guiding cylinder 3 , motor 4, water retaining plate 5, inclined pipe mounting plate 6, inclined pipe 601, suspension rod 602, top support connecting rod 7, threaded rod 8, vertical installation rod 9, horizontal support rod 901, positioning insertion rod 10 , install the support frame 11 and the screw feeding pipe 12; the settling tank 1 is arranged in a rectangular shape as a whole, and the right side spacer rail of its inside is welded with the water baffle 5 and the first spacer plate 104, and the first spacer plate 104 The height is higher than the water retaining plate 5, and the end of the water retaining plate 5 is not directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com