Method for improving spot-welding quality of laser spot-welded duct plate

A solder joint quality, laser spot welding technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve problems such as breakdown of air duct plates, scrapping, affecting the strength and apparent quality of solder joints, etc., to improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

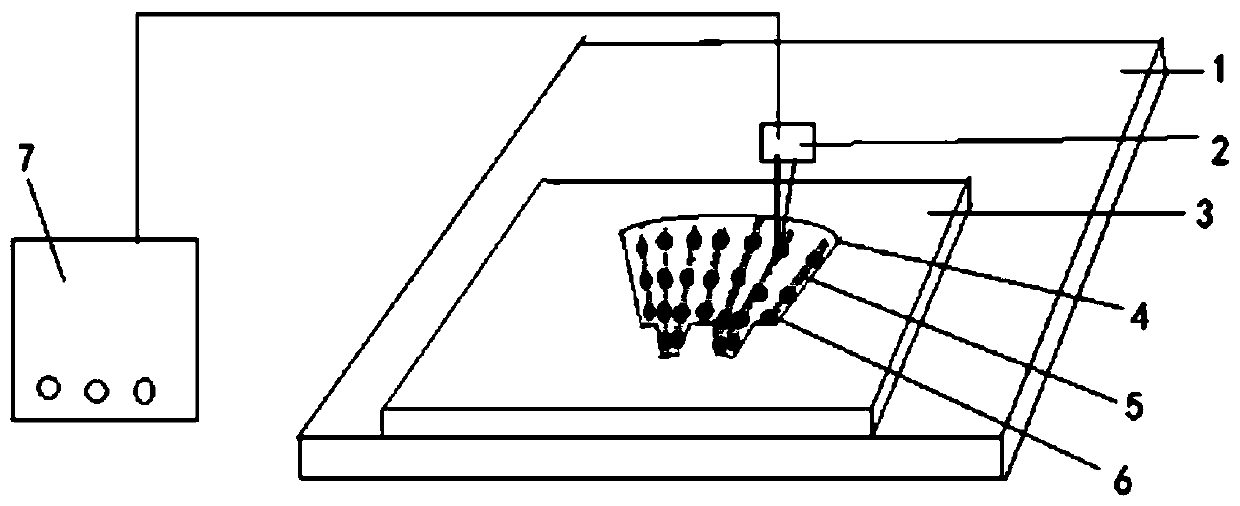

[0017] see figure 1 , a method for improving the quality of laser spot welding air duct plate solder joints of the present invention is used for welding on the surface of the air duct plate, and is characterized in that it comprises the following steps:

[0018] In step 1, the positioning tool 3 is hoisted to the workbench 1, and then the positioning tool 3 is fixed by positioning pins.

[0019] Step 2, place the workbench 1 at the limit position of the corner of the work area, so that it is easy to locate and difficult to cause relative displacement. Since it is necessary to inspect the solder joints of the sample after the trial run, the determined limit position can ensure that the position of the workbench 1 is consistent before and after the inspection and does not deviate.

[0020] Step 3. Divide all the air ducts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com