Friction Spot Welding Tool and Method for Material Continuous Inheritance Filling

A friction point and tool technology, applied in the field of lap joint welding, can solve the problems of insufficient reliability and poor consistency of mechanical properties of solder joints, and achieve the effect of promoting interface reaction, good reliability and efficient friction processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will combine Figure 1 to Figure 9Further detailed description is made on the friction spot welding tool and method of material continuous inheritance filling of the present invention.

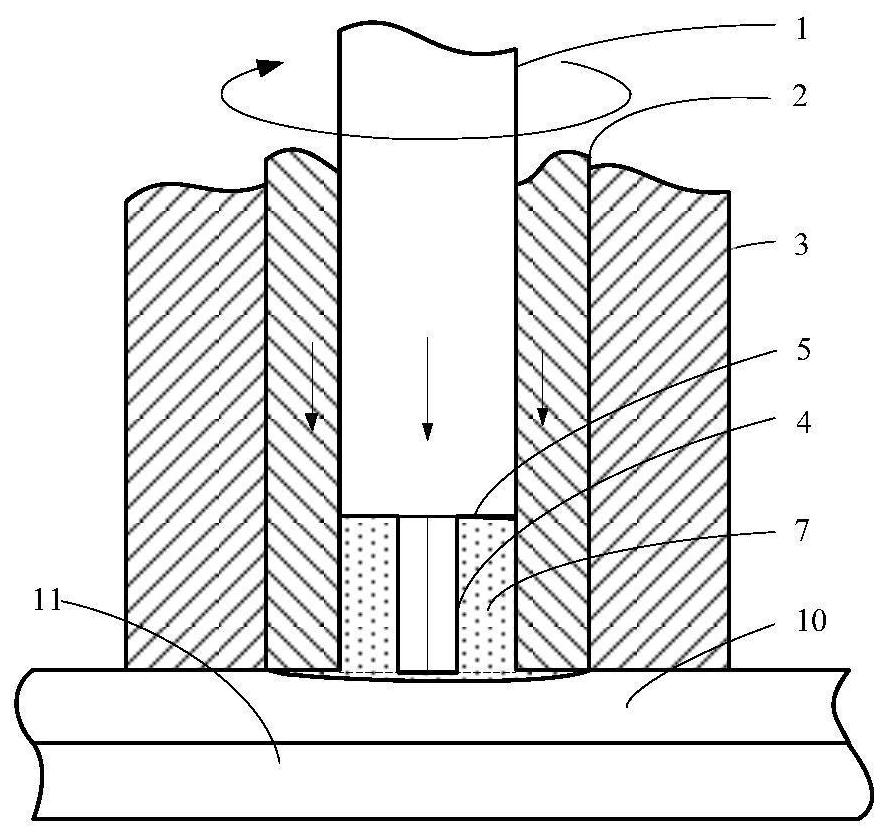

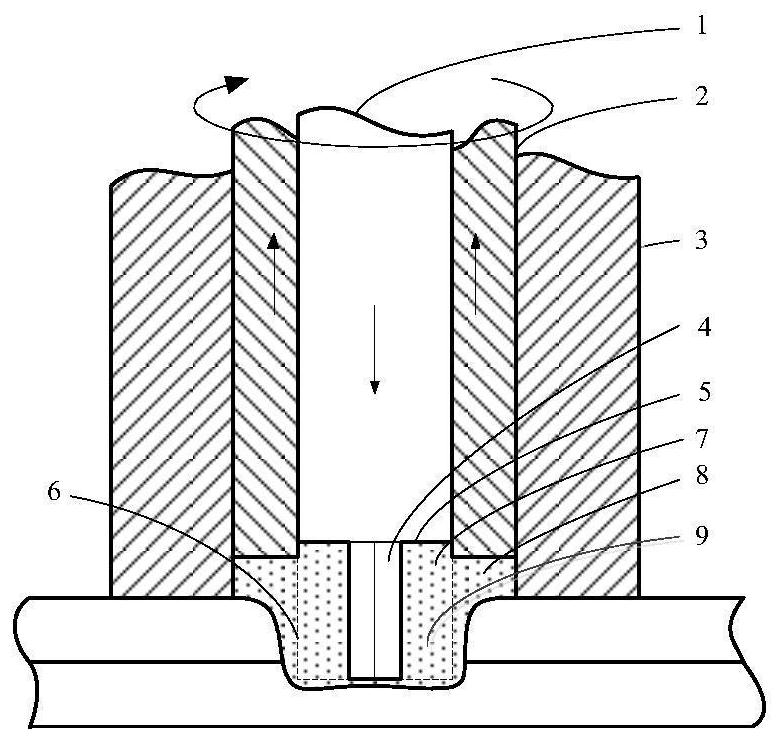

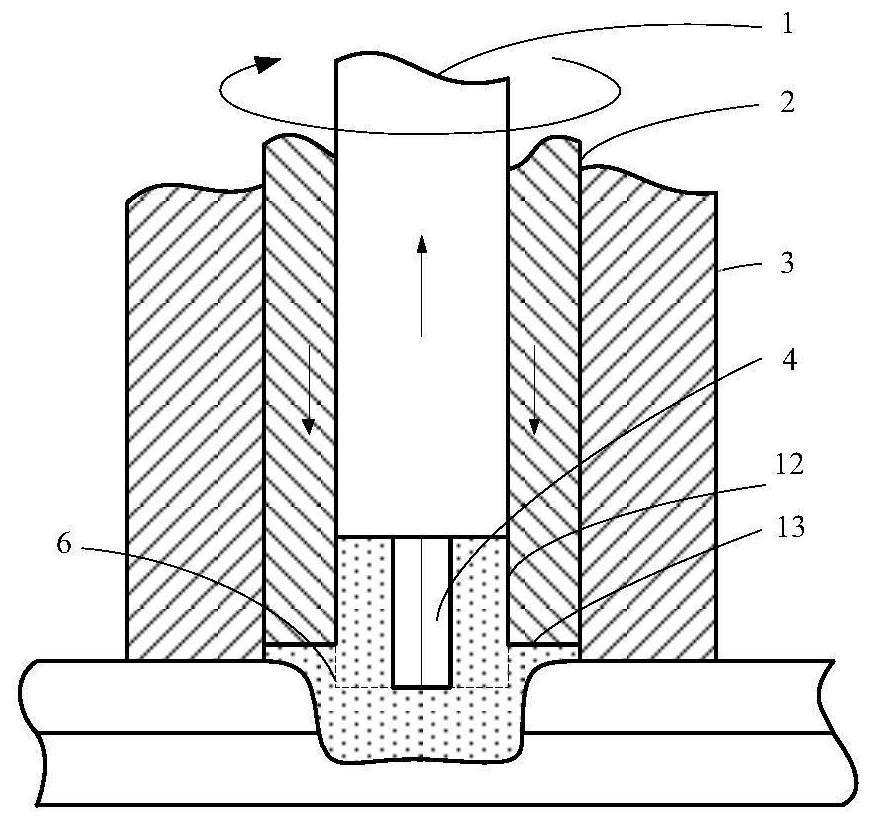

[0035] figure 1 Shown is the schematic diagram of the welding preparation stage in the material continuous inheritance filling friction spot welding method of the present invention; figure 2 Shown is the schematic diagram of the welding pressing stage in the material continuous inheritance filling friction spot welding method of the present invention; image 3 Shown is the schematic diagram of the welding backfill stage in the material continuous inheritance filling friction spot welding method of the present invention; Figure 4 Shown is a schematic diagram of the welding point trimming and welding end stages in the material continuous inheritance filling friction spot welding method of the present invention.

[0036] see Figure 1 to Figure 4 The friction spot weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com