A double eccentric tip

A double eccentric, top technology, applied in the direction of tailstock/top, toolholder accessories, metal processing equipment, etc., can solve the problems of long adjustment time and low processing efficiency, so as to improve efficiency, improve processing efficiency, avoid Effect of Angle Offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

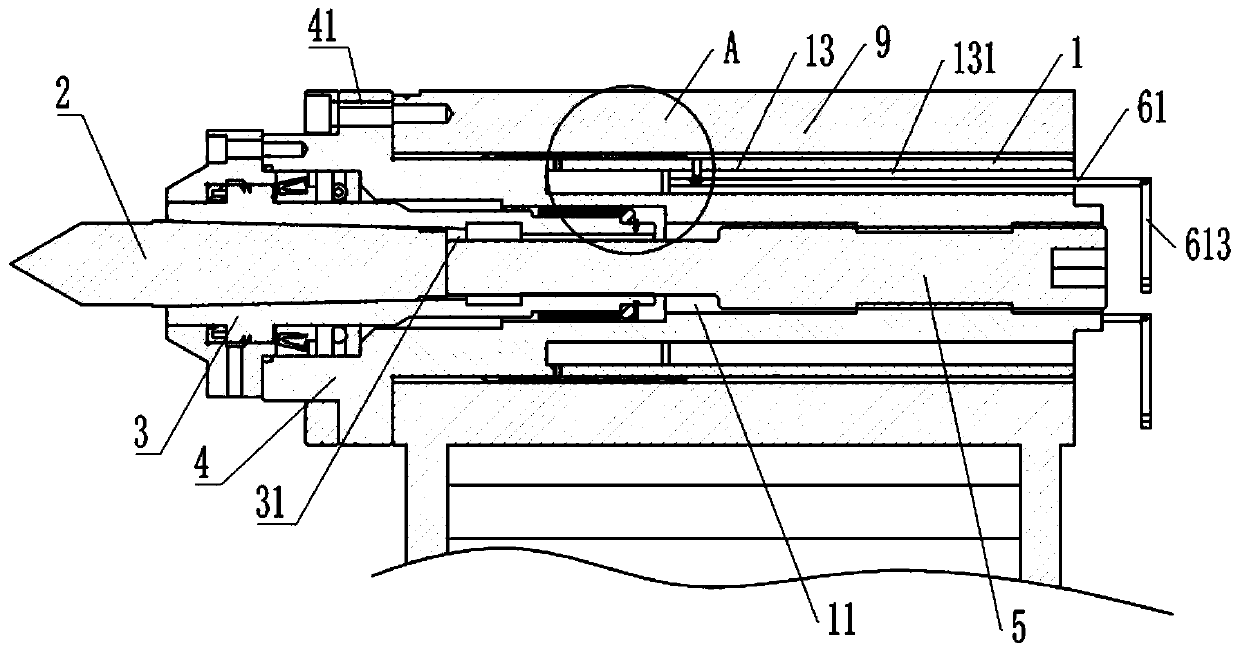

[0036] A double eccentric top, basically as attached figure 1 As shown, it includes a sleeve 1, a thimble 2, a mandrel 3 and a push rod 5. A connection plate 4 is provided on the outer wall of the left part of the sleeve 1, and three arc-shaped mounting holes 41 are provided on the connection plate 4 along the circumference. The sleeve 1 is provided with an eccentric hole 11, the eccentric hole 11 is a stepped hole, the mandrel 3 is installed on the left end of the eccentric hole 11, and the left end of the mandrel 3 protrudes from the left end of the eccentric hole 11; the eccentric hole 11 is located between the sleeve 1 and the core Two sets of bearings are arranged between the shafts 3, and the two sets of bearings are respectively located at the left and right ends of the mandrel 3. A sealing cover is installed on the part of the left end of the mandrel 3 outside the eccentric hole 11, and the right end of the sealing cover is against the left end of the sleeve 1; a rotar...

Embodiment 2

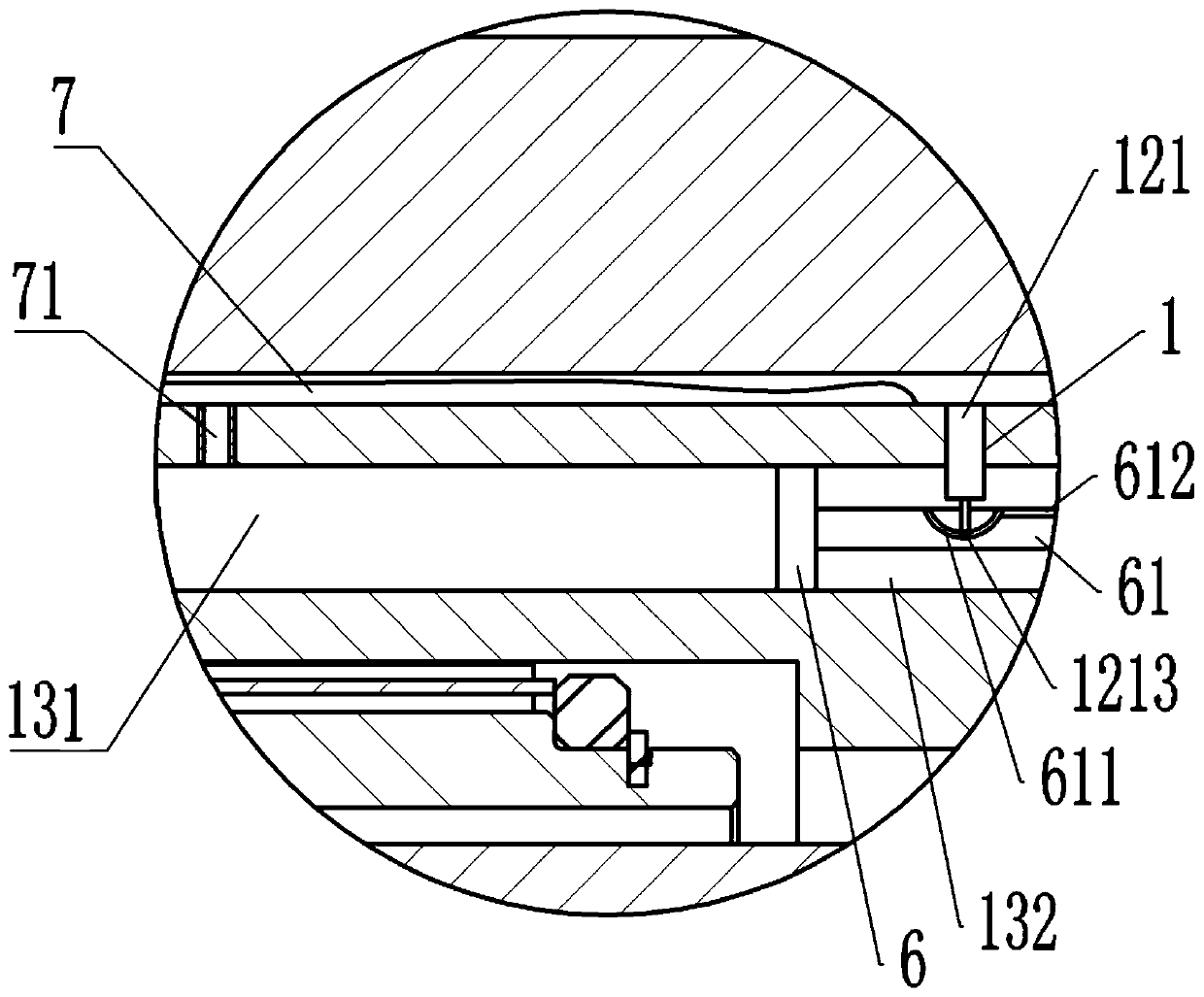

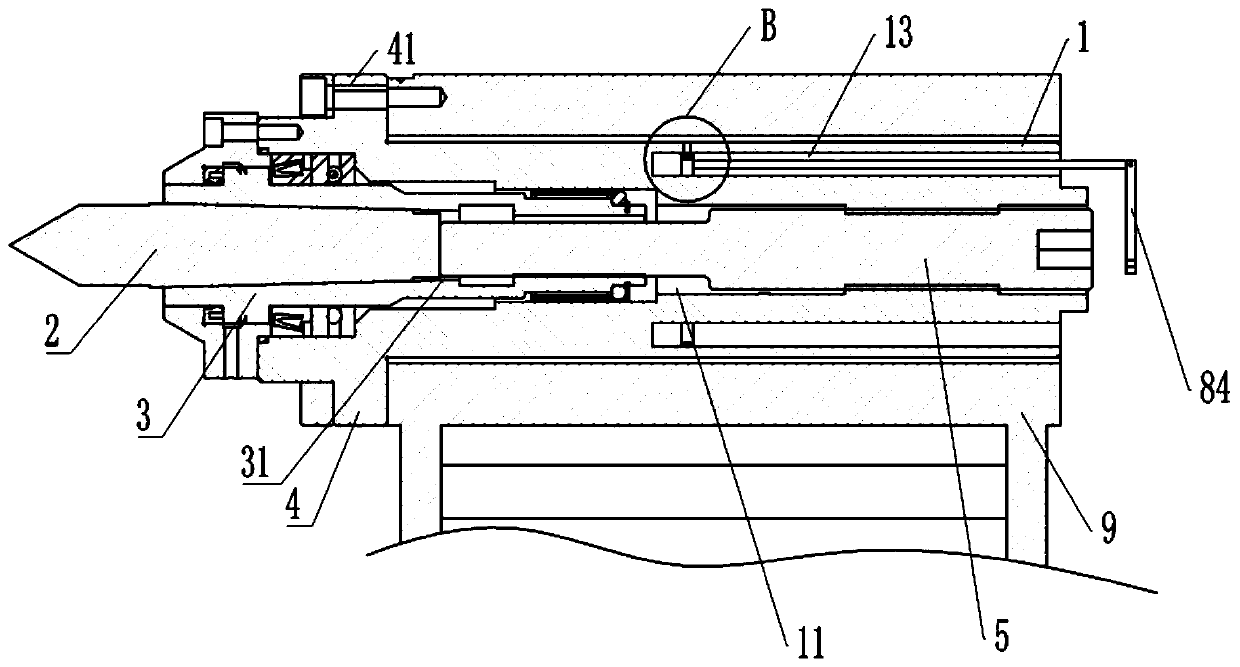

[0044] The difference between this embodiment and embodiment 1 is only that, as image 3 , Figure 4 As shown, the driving member includes an annular groove 13 arranged on the sleeve 1 and coaxial with the sleeve 1 , and the annular groove 13 is located on the outer ring of the eccentric hole 11 . The annular groove 13 communicates with the sliding groove 12, and the rotating ring 8 is connected in the annular groove 13, and the outer wall of the rotating ring 8 is provided with three placing grooves 81, and the outer wall of the rotating ring 8 is provided with an annular moving groove 82, and the moving groove 82 It is a T-shaped slot, and the moving slot 82 covers the placing slot 81 . The inner end of the positioning rod 121 is provided with a T-shaped block 1213 , and the T-shaped block 1213 is located in the moving groove 82 at the placement groove 81 , and the T-shaped block 1213 is slidably connected in the moving groove 82 . The right end surface of the rotating rin...

Embodiment 3

[0048] The only difference between this embodiment and embodiment 1 or embodiment 2 is that, as Figure 5 As shown, the positioning rod 121 includes a pressing part 1211 and a pushing part 1212, the pushing part 1212 is connected with the T-shaped block 1213, the bottom of the pressing part 1211 is provided with a sliding hole, and the top of the pushing part 1212 is vertically slidably connected in the sliding hole, and A spring is disposed between the pushing portion 1212 and the sliding hole. Sliding can occur between the positioning part 132 and the pushing part 1212, and a spring is provided between the two, so when the pressing part 1211 is worn for a long time, the tailstock 9 can also be continuously pressed against the tailstock 9 under the action of the spring .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com