TEST TRAY AND sorting machine for testing electronic components

A technology for electronic components and test trays is applied in the field of sorting machines for testing electronic components, which can solve the problems of cost burden or reduced processing speed, inability to apply existing technology, expensive test machines, etc., so as to reduce waste of resources or cost burden, Minimize processing capacity, minimize the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Preferred embodiments according to the present invention will be described with reference to the accompanying drawings, and for the sake of brevity of the description, the description of the repeated or substantially the same configuration will be omitted or condensed as much as possible.

[0053]

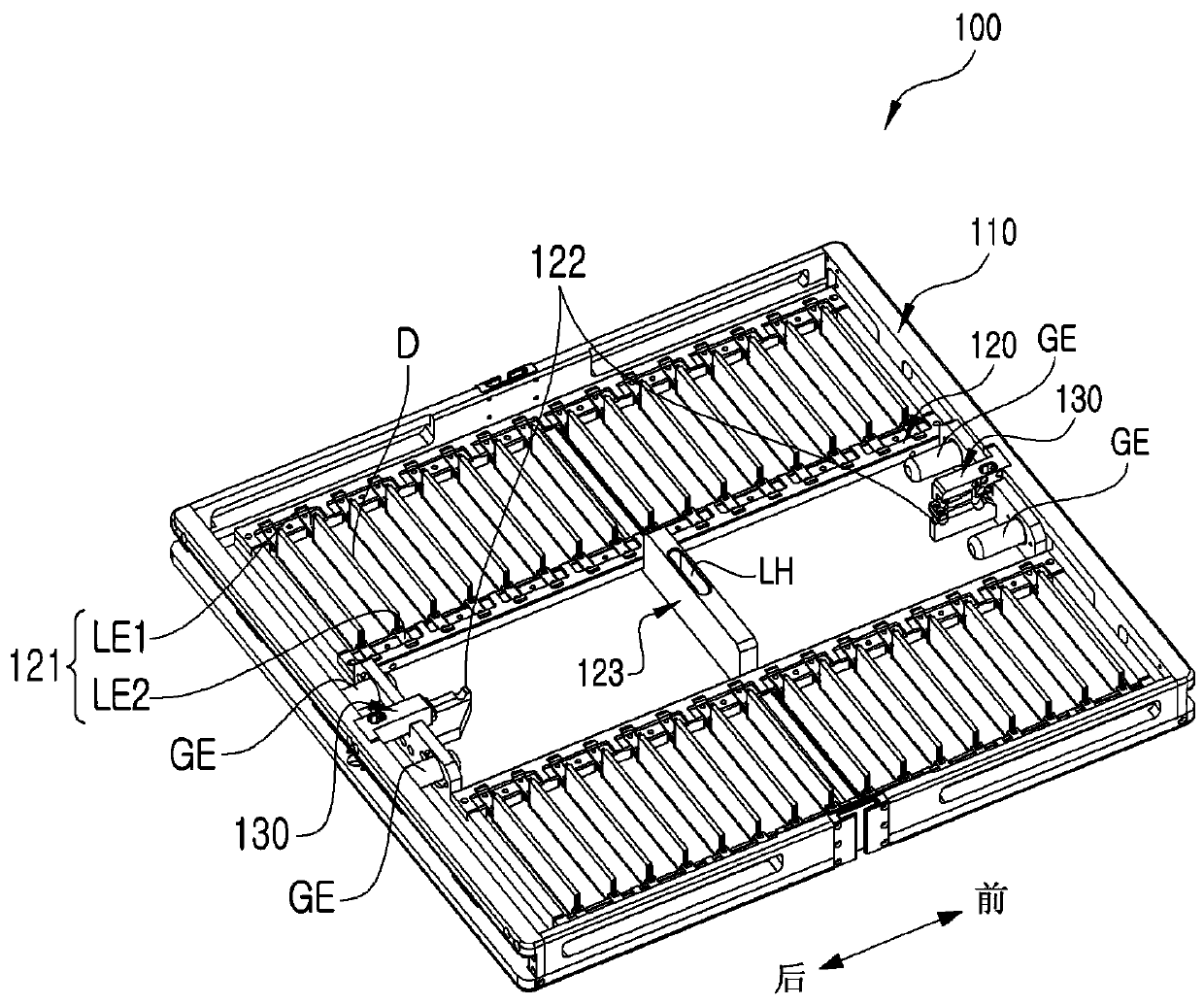

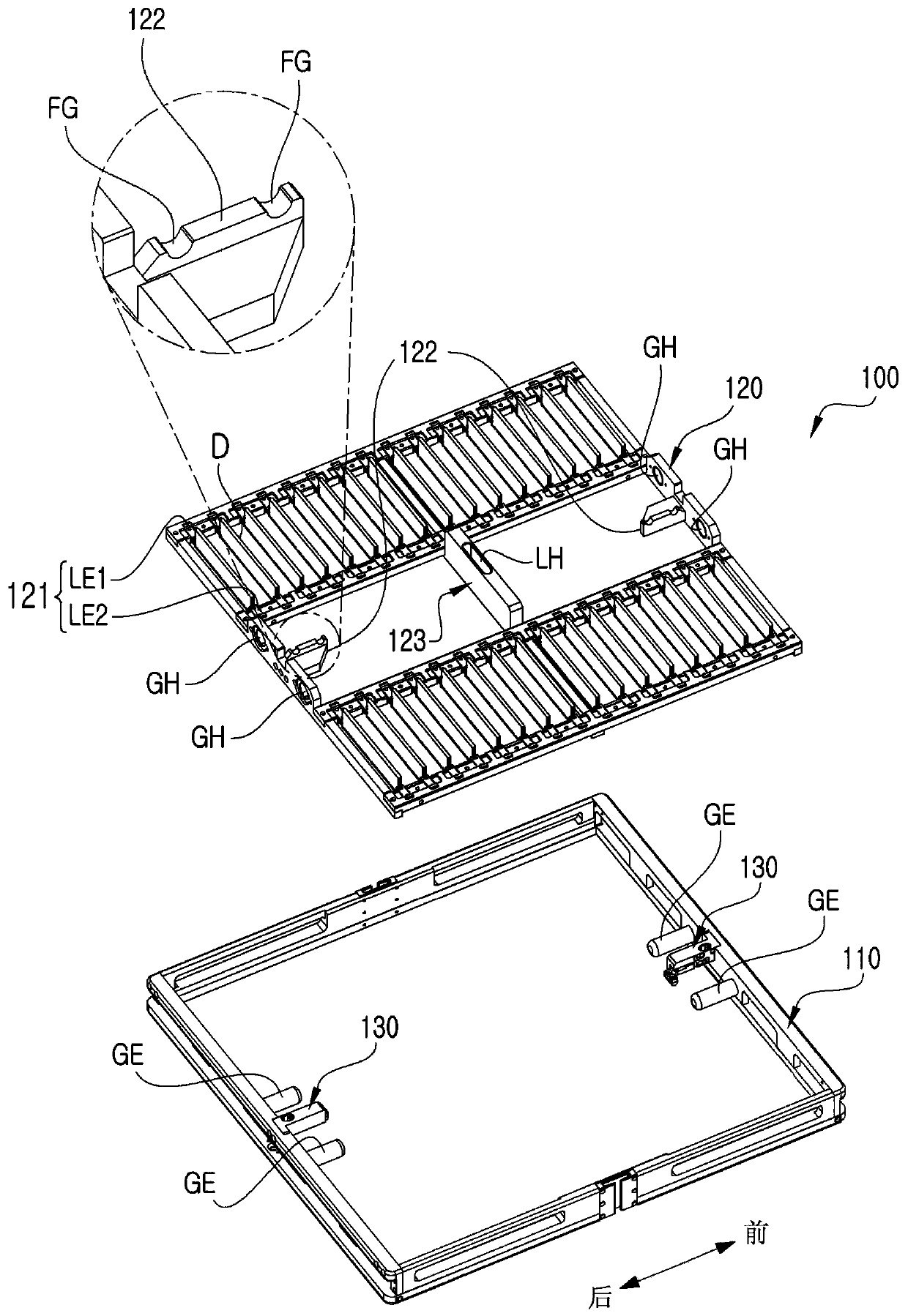

[0054] figure 1 is a perspective view of the test tray 100 according to the present invention, figure 2 its about figure 1 An exploded perspective view of the test tray 100.

[0055] like figure 1 and figure 2 As shown, the test tray 100 includes an outline frame 110 , a loading frame 120 and a pair of holders 130 .

[0056] The outline frame 110 determines the outline size of the test tray 100 . In addition, a loading frame 120 and a holder 130 are provided on the outer frame frame 110 . Such an outer frame 110 is equipped with four guides GE for guiding the movement of the loading frame 120 and supporting the loading frame 120 .

[0057] Two of the four guides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com