System and method for adsorbing and purifying flue gas by using active coke

A technology of activated coke and flue gas, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of secondary pollution of ammonia and increase of ammonia consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

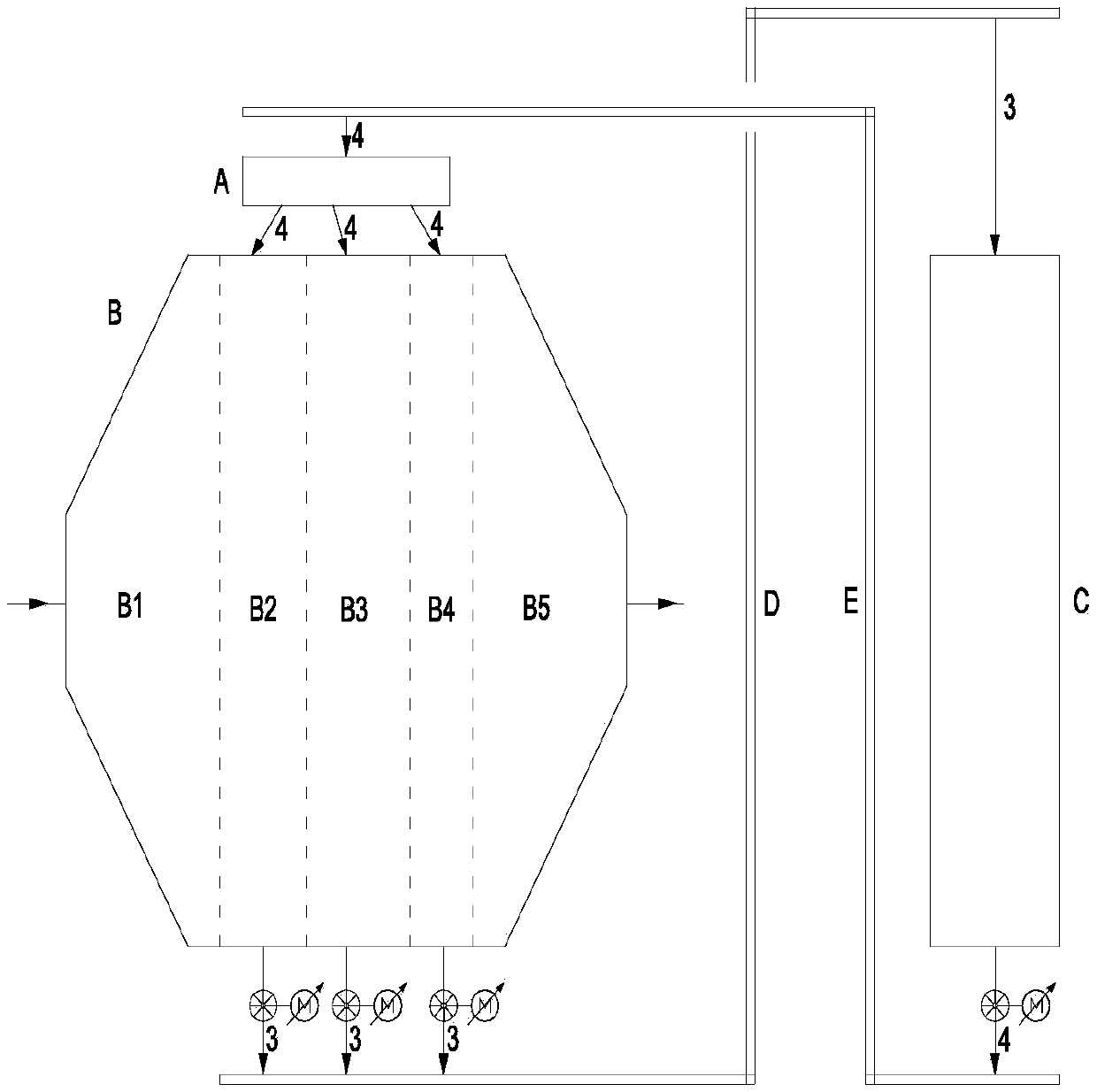

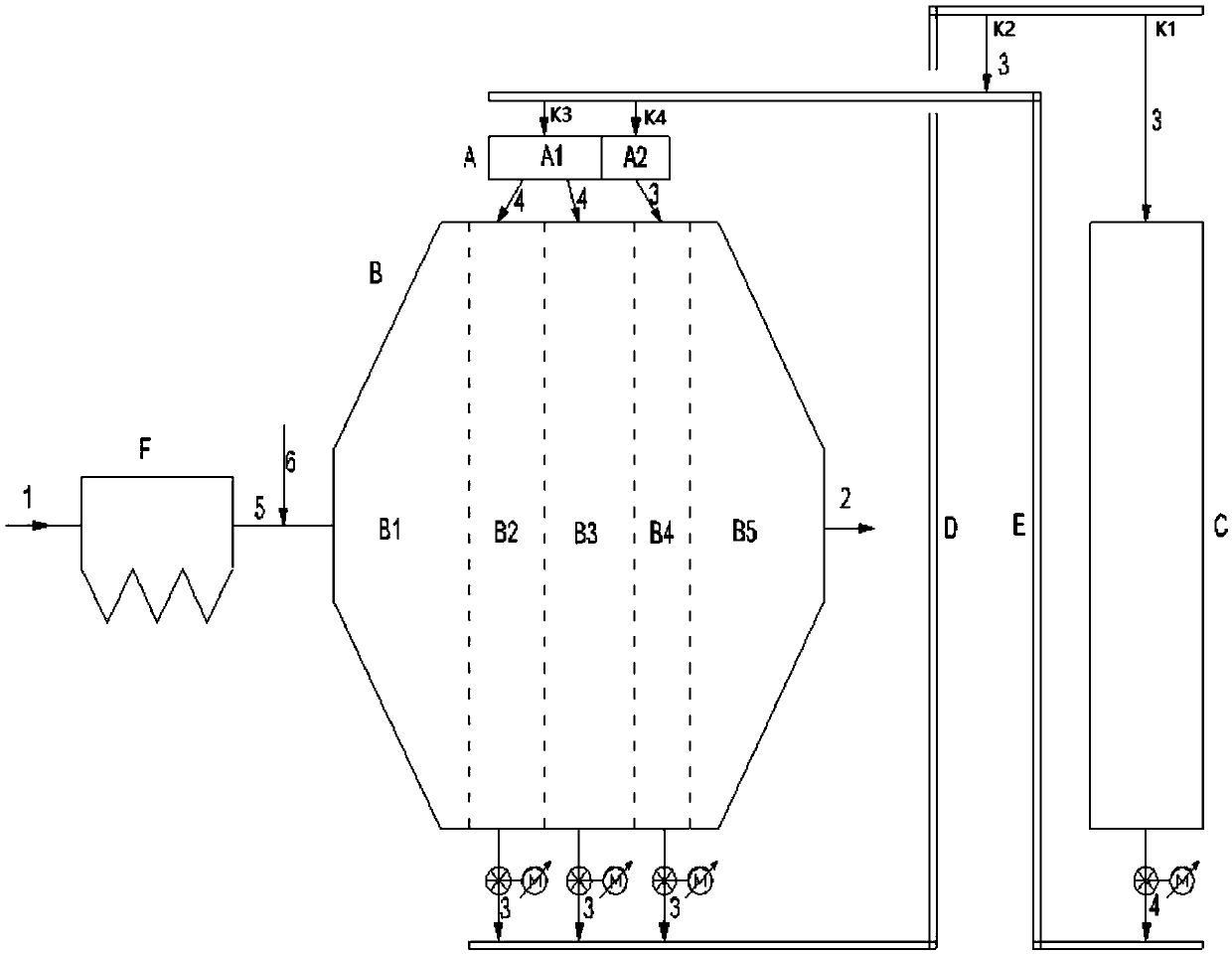

[0067] Such as figure 2 As shown, the flue gas raw material 1 to be treated first enters the dust collector (cloth bag or electric bag) F for dust removal, and the obtained flue gas 5 after dust removal is mixed with the injected ammonia gas 6 and then enters the inlet distribution of the adsorption tower B Then enter the front room B2 of the adsorption tower for desulfurization and pre-dust removal, then enter the middle room B3 for desulfurization and denitrification, and then enter the back room B4 after desulfurization and denitrification, after the flue gas in the back room cross-flow contacts with the coke to be produced Capturing the ammonia in the flue gas and converting it to ammonium sulfate can greatly reduce the ammonia slip in the clean flue gas. The clean flue gas from the back room B4 enters the outlet distribution area B5, and then leaves the adsorption tower through the flue gas outlet to obtain purified flue gas 2.

[0068] The regenerated coke 4 enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com