Railroad bed active vibration reduction and isolation model testing device and testing method

A model test device and railway subgrade technology, which is applied to roads, uses a single impact force to test the strength of materials, tracks, etc., and can solve problems such as difficulty in ensuring compactness, large model volume, large manpower and material resources, and achieve model testing. Good effect, convenient installation and disassembly, convenient production and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structure of the railway roadbed active vibration reduction and isolation model test device of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

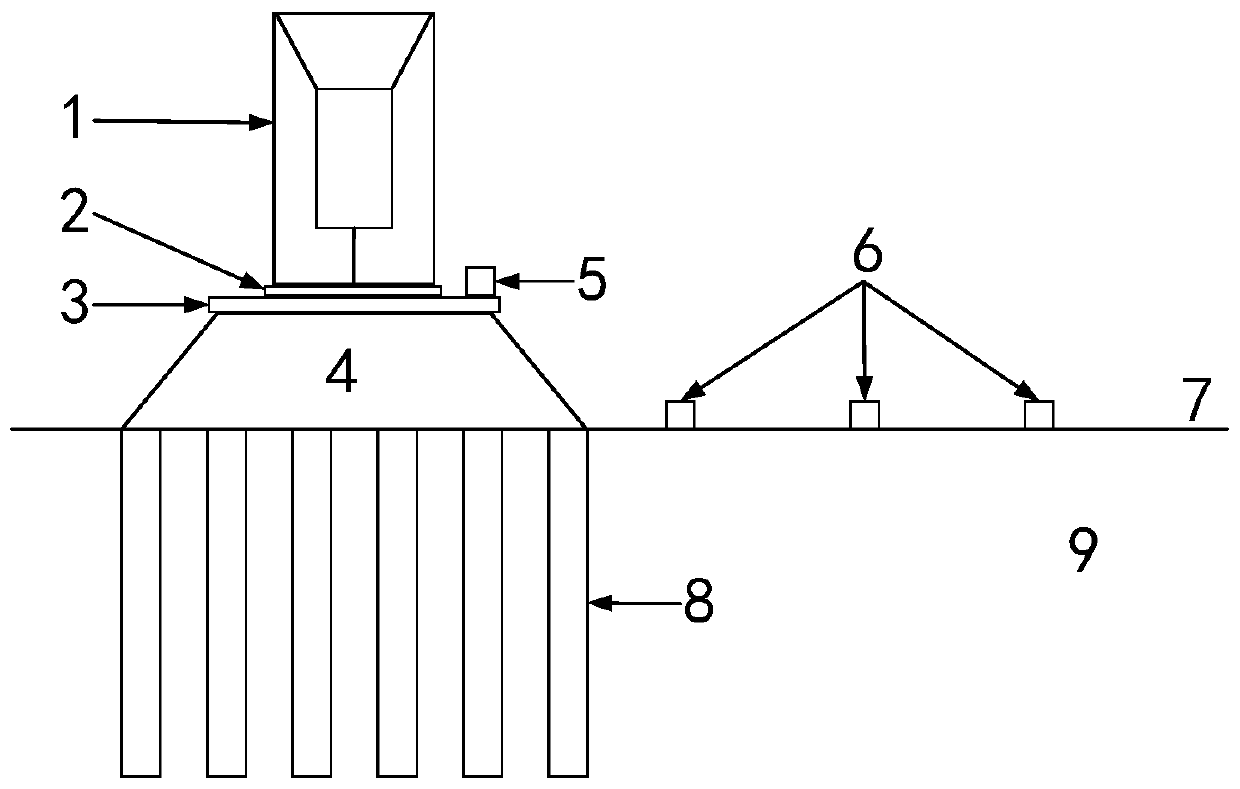

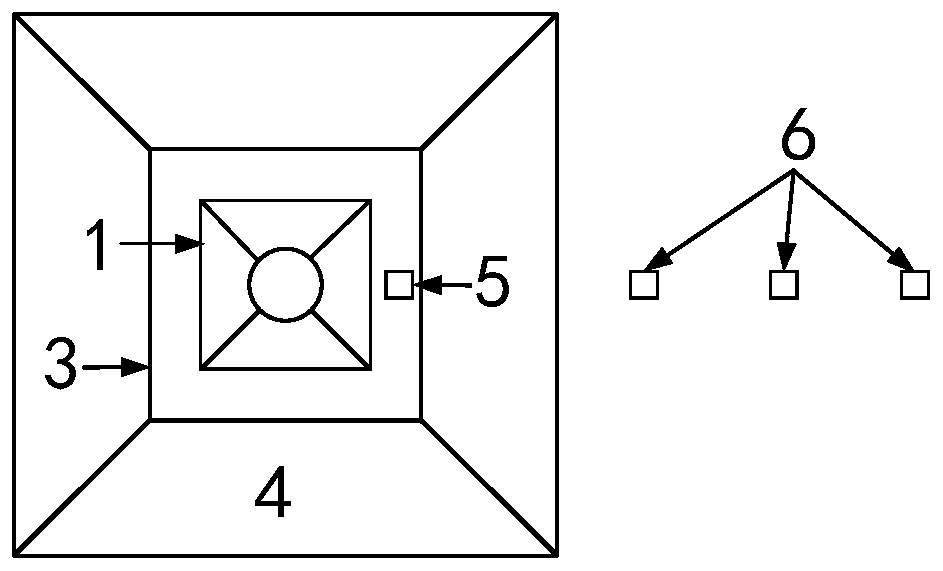

[0041] Such as Figure 1 to Figure 3 As shown, the railway roadbed active vibration reduction and isolation model test device of the present invention is composed of a homogeneous foundation 9, a reference working condition test device and a plurality of comparative working condition test devices.

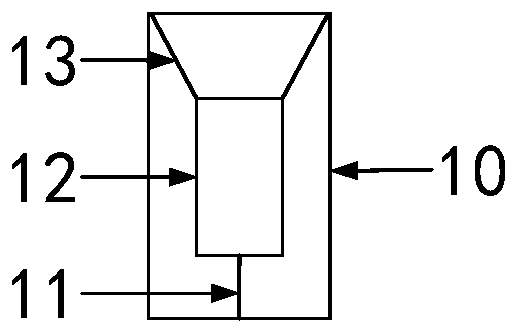

[0042] The reference working condition test device is used to form the vibration propagation attenuation law curve of the reference working condition, including embankment 4, rigid plate 3, flexible cushion 2 and vibration excitation system. Among them: the embankment 4 is filled on the homogeneous foundation 9 according to the scale ratio; the rigid plate 3 is placed on the top surface of the embankment 4; the flexible cushion layer 2 is laid on the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com