Linear sliding rail lubrication system of shielding door

A linear slide rail and lubrication system technology, applied in the direction of lubricating parts, engine lubrication, lubricating oil control valve, etc., can solve the problem of unable to fill the oil tank of the line rail slider oil tank, so as to avoid dry grinding of the line rail surface and timely replenishment , the effect of convenient replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

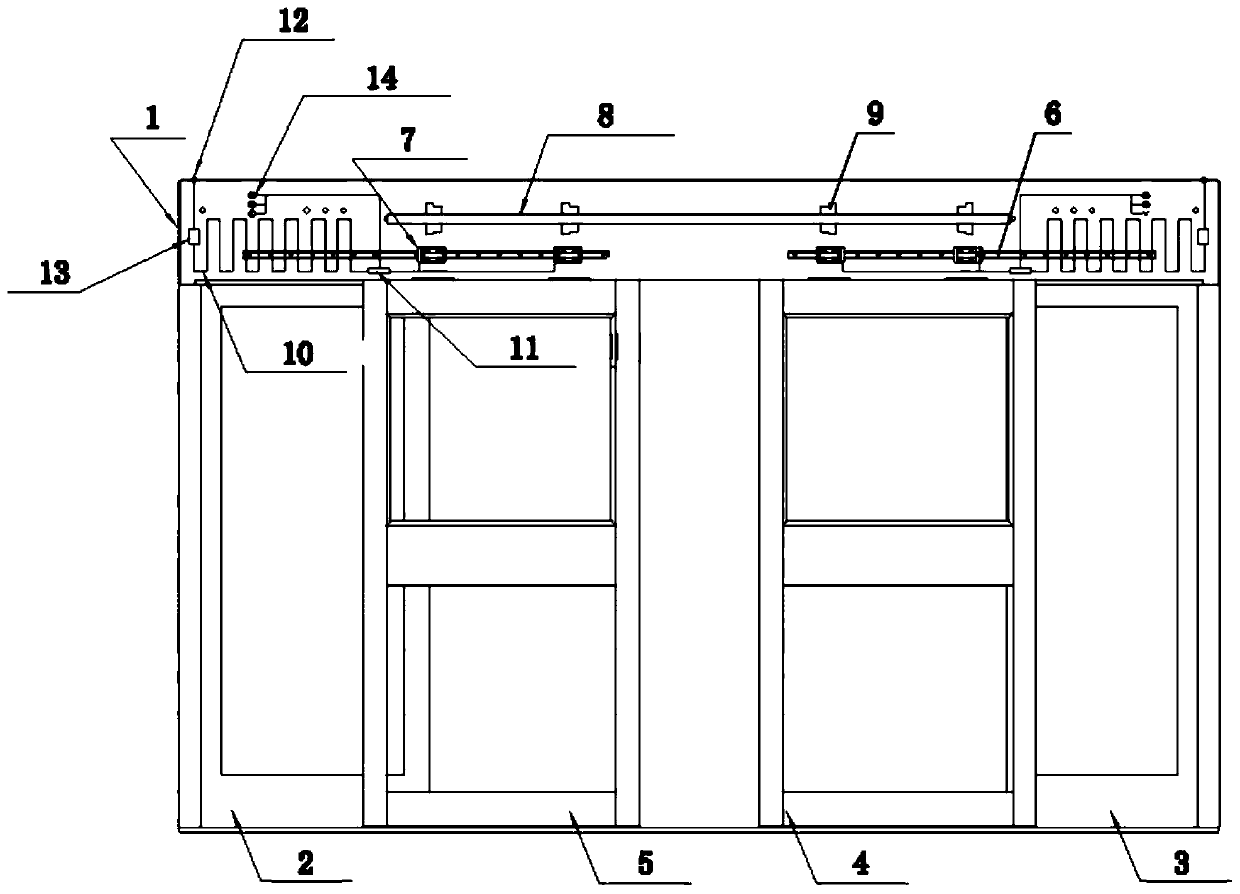

[0021] see Figure 1-2 , the present invention provides a technical solution: a linear sliding rail lubrication system for shielded doors, including a light box sheet metal frame 1, a left fixed door 2, a right fixed door 3, a right movable door 4 and a left movable door 5, and a left fixed door 2 , the right fixed door 3 is respectively fixedly connected to the left and right ends of the light box sheet metal frame 1, the left movable door 5 and the right movable door 4 are respectively movably supported on the left side and the middle right side of the metal frame 1, and the right movable door 4 and The left movable door 5 can move laterally on the golden frame 1, and the right movable door 4 moves laterally on the middle right side of the golden frame 1, and the left movable door 5 moves laterally on the middle left side of the golden frame 1;

[0022] The upper ends of the left movable door 5 and the right movable door 4 are fixedly connected with a self-lubricating oil ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com