Emergency fire pump of marine diesel engine

A technology for marine diesel engines and fire pumps, applied to pumps, pump components, mechanical equipment, etc., can solve problems such as many fault points, long water discharge time, and impeller cavitation, so as to reduce the probability of failure and overcome the easy wear and tear of pumping water , to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

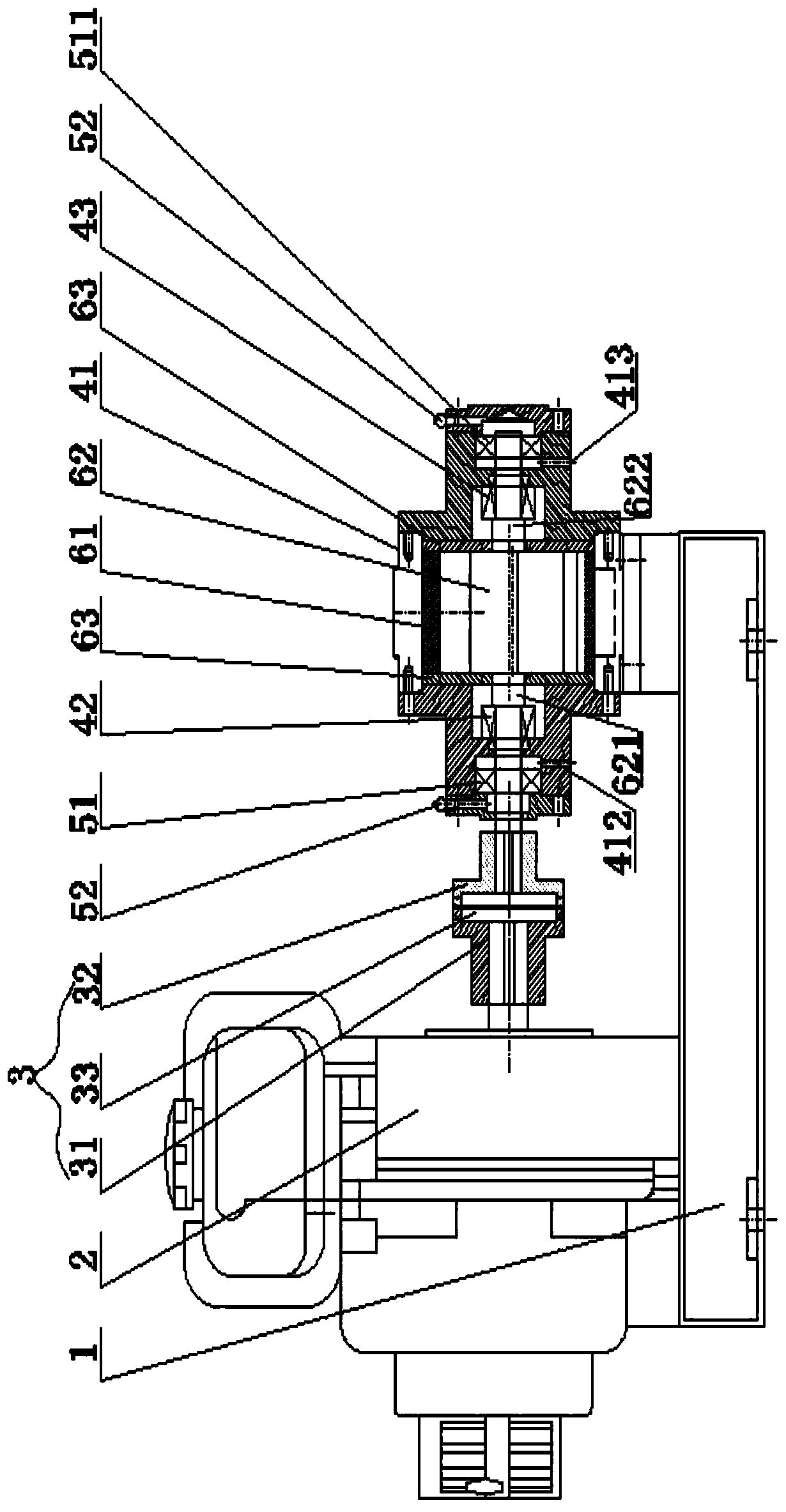

[0072] Such as Figure 1-3 Shown, the structure of the present invention is as follows:

[0073] A marine emergency fire pump, comprising a base 1, a diesel engine 2, a coupling 3 and a vane pump; the diesel engine 2 and the vane pump are connected through a coupling 3, and both the diesel engine 2 and the vane pump are fixed on the base 1 .

[0074] Wherein, the sliding vane pump includes a pump body 41, and the diesel engine 2 and the pump body 41 are all fixed on the base 1;

[0075] A first bearing chamber and a rotor chamber are respectively arranged in the pump body 41 along the axial direction, and a first mechanical seal structure 42 is arranged between the first bearing chamber and the rotor chamber;

[0076] A first bearing 51 is installed on the inner wall of the first bearing chamber;

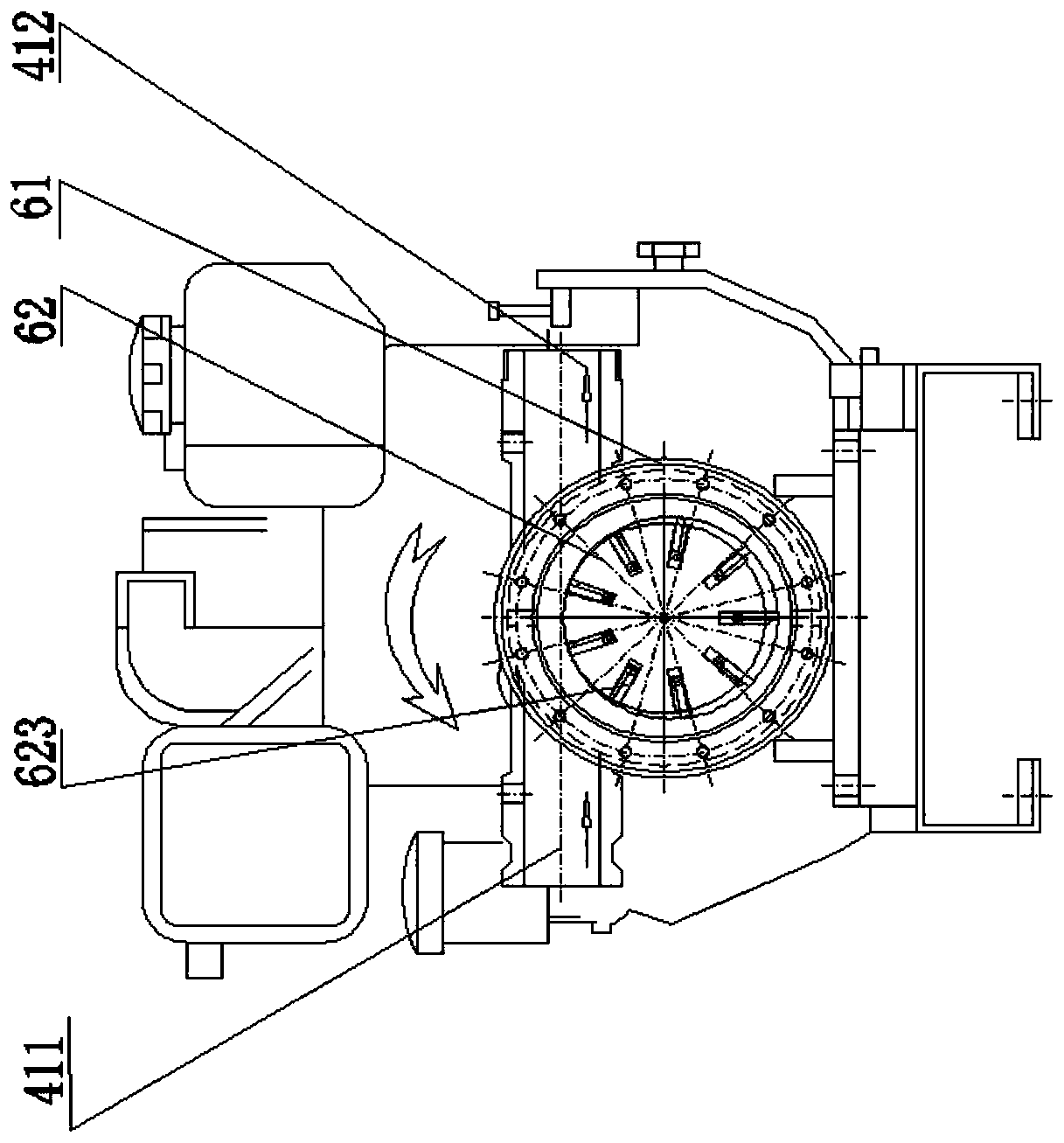

[0077] The two sides of the top of the rotor chamber are respectively provided with a water inlet 411 and a water outlet 412. An eccentric stator 61 and a rotor 62 are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com