Locknut capable of clamping and capable of interlocking

A technology for locking nuts and nuts, applied in the directions of nuts, screws, bolts, etc., can solve the problems that the locking nuts cannot be interlocked, manufacturing, and inconvenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

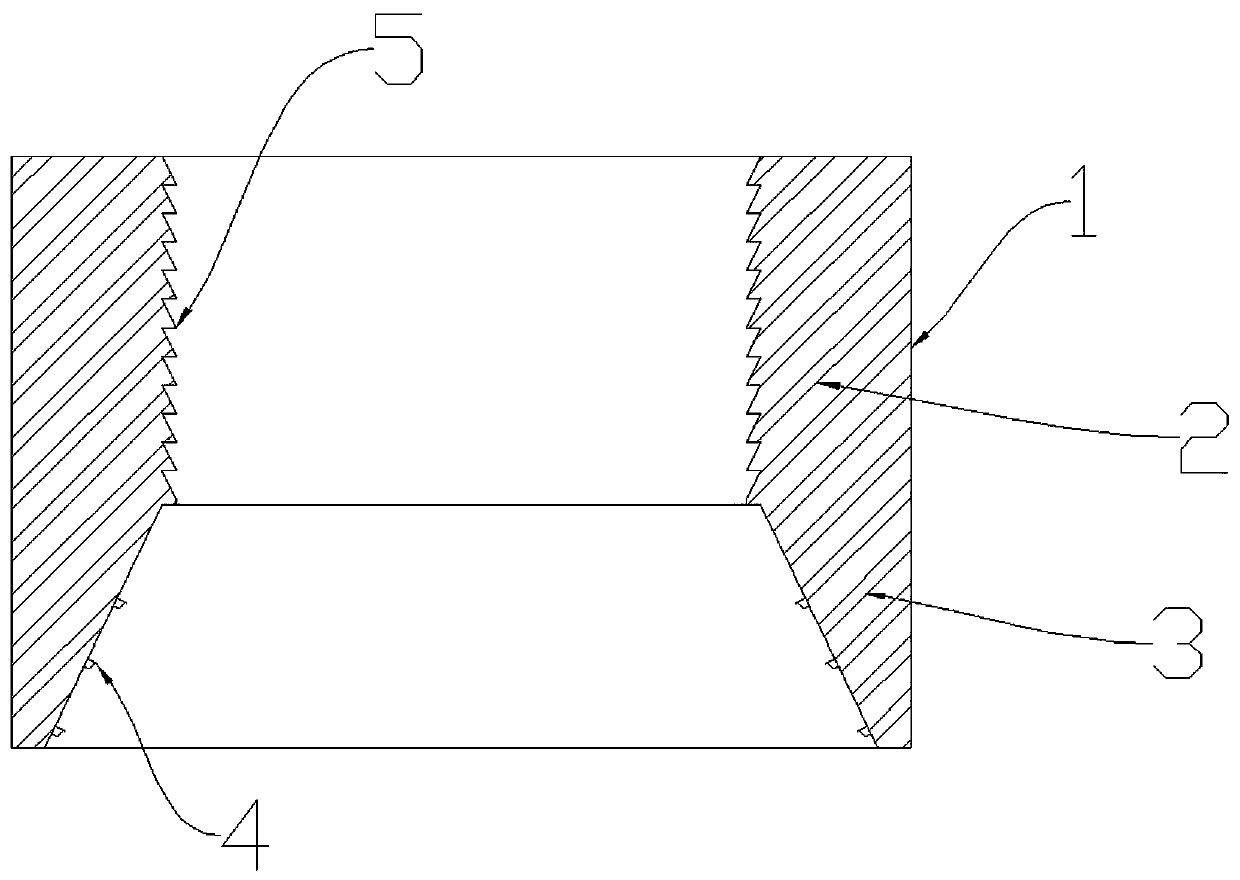

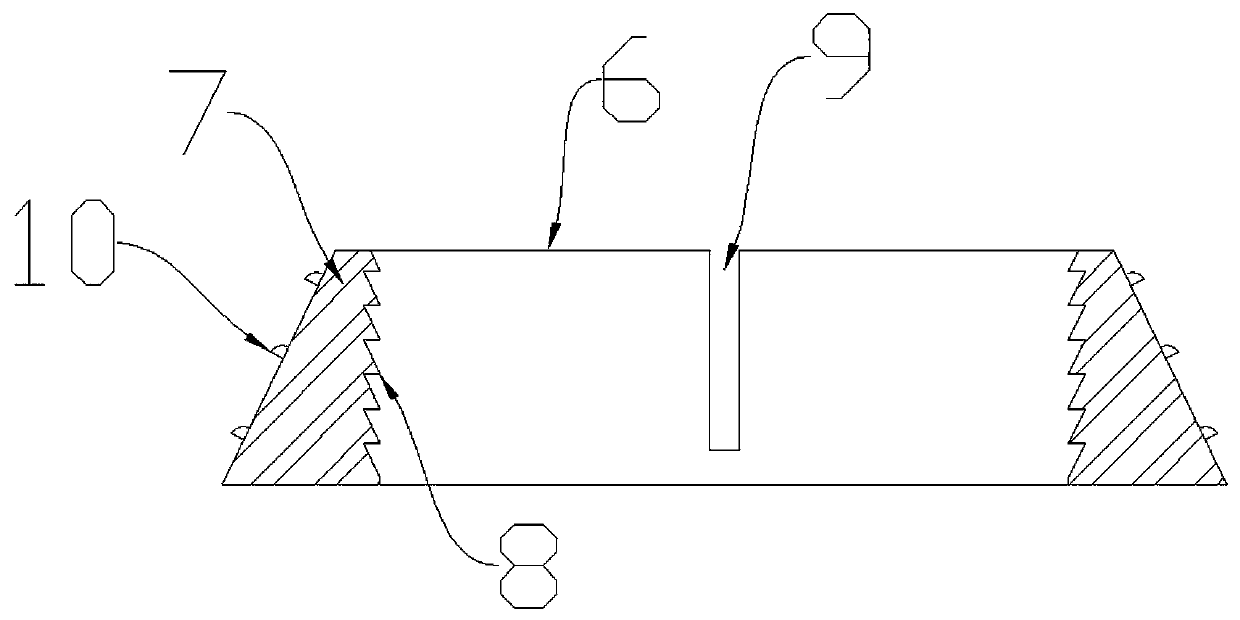

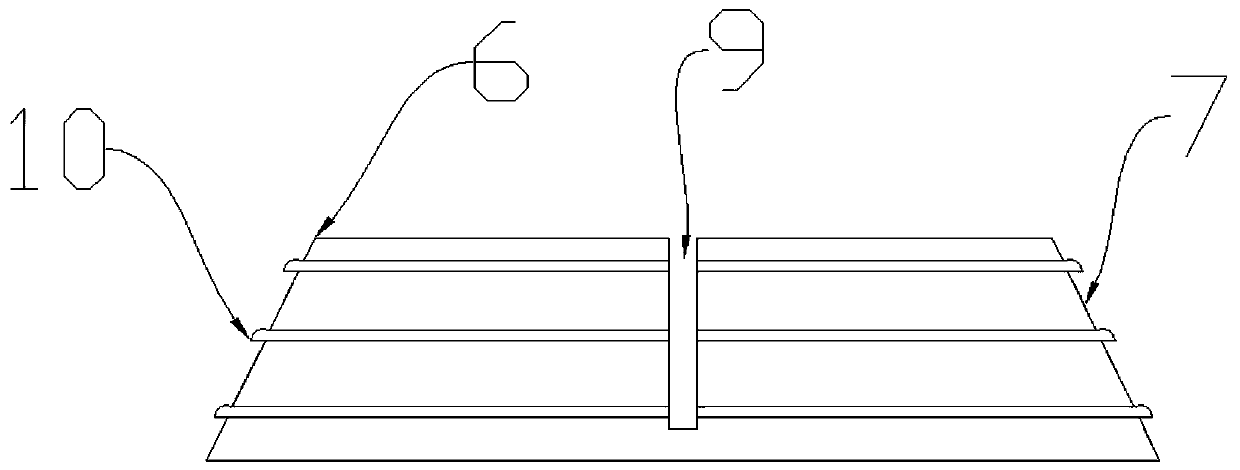

[0014] see Figure 1 to Figure 9 , first tighten the nut B6 on the bolt 11 and press the lower end of the nut B6 against the workpiece 12 with the small surface of the truncated cone facing upwards, then screw the extruded part 3 of the nut A1 downwards on the bolt 11. During the tightening process, the multiple convex ribs A4 of the nut A1 and the multiple convex ribs B10 of the nut B6 are tightly attached to each other, and the nut A1 is continued to be tightened, the arc surface A 17 of the multiple convex ribs A4 of the nut A1 and the multiple convex ribs B10 of the nut B6 are in close contact with each other. The arc surface B15 of the convex rib B10 is first extruded and elastically compressed, and when the arc surface A17 of the plurality of convex ribs A4 of the nut A1 passes down the arc surface B15 of the corresponding plurality of convex ribs B10 of the nut B6, the nut The multiple convex ribs A4 of A1 and the multiple convex ribs B10 of the nut B6 undergo elastic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com