A high-efficiency gas-phase blasting dredging device for coal hole blockage and its preparation method

A coal-sliding, high-efficiency technology, which is applied to the high-efficiency coal-sliding hole blockage gas-phase blasting dredging device and preparation field, can solve the problems of harsh construction environment on site, reduced work efficiency, poor safety of construction personnel, etc., to overcome serious environmental pollution, Reduce labor intensity and cost, overcome the effect of insufficient recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

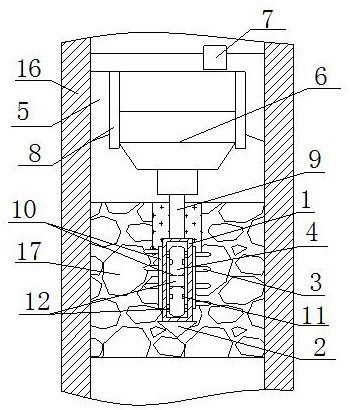

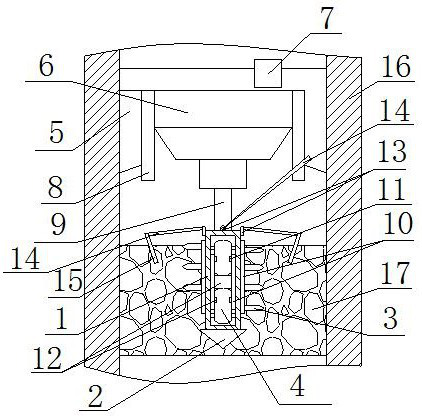

[0038] like figure 1Said a kind of high-efficiency gas-phase blasting dredging device for coal hole blockage includes a positioning keel 1, an auger bit 2, a positioning plate 3, a gas-phase pressure device 4, a positioning frame 5, a feed drive mechanism 6 and a control circuit 7, wherein the positioning machine The frame 5 is a frame structure in which the axis and the horizontal plane are vertically distributed. At least three driving guide rails 8 are uniformly distributed around the axis of the positioning frame on its inner surface, and the axis of the driving guide rails is distributed parallel to the axis of the positioning frame 5. The feed drive mechanism 6 is embedded in the In the positioning frame 5, it is distributed coaxially with the positioning frame 5 and is slidingly connected with the inner surface of the positioning frame 5 through the driving guide rail 8. The lower end surface of the feed drive mechanism 6 is connected with the upper end surface of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com