Climbing frame with lifting conveying function

A functional climbing frame technology, applied in the field of climbing frames with lifting and conveying functions, can solve the problems of increased possibility of falling objects, increased safety risks, and inconvenient wall operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

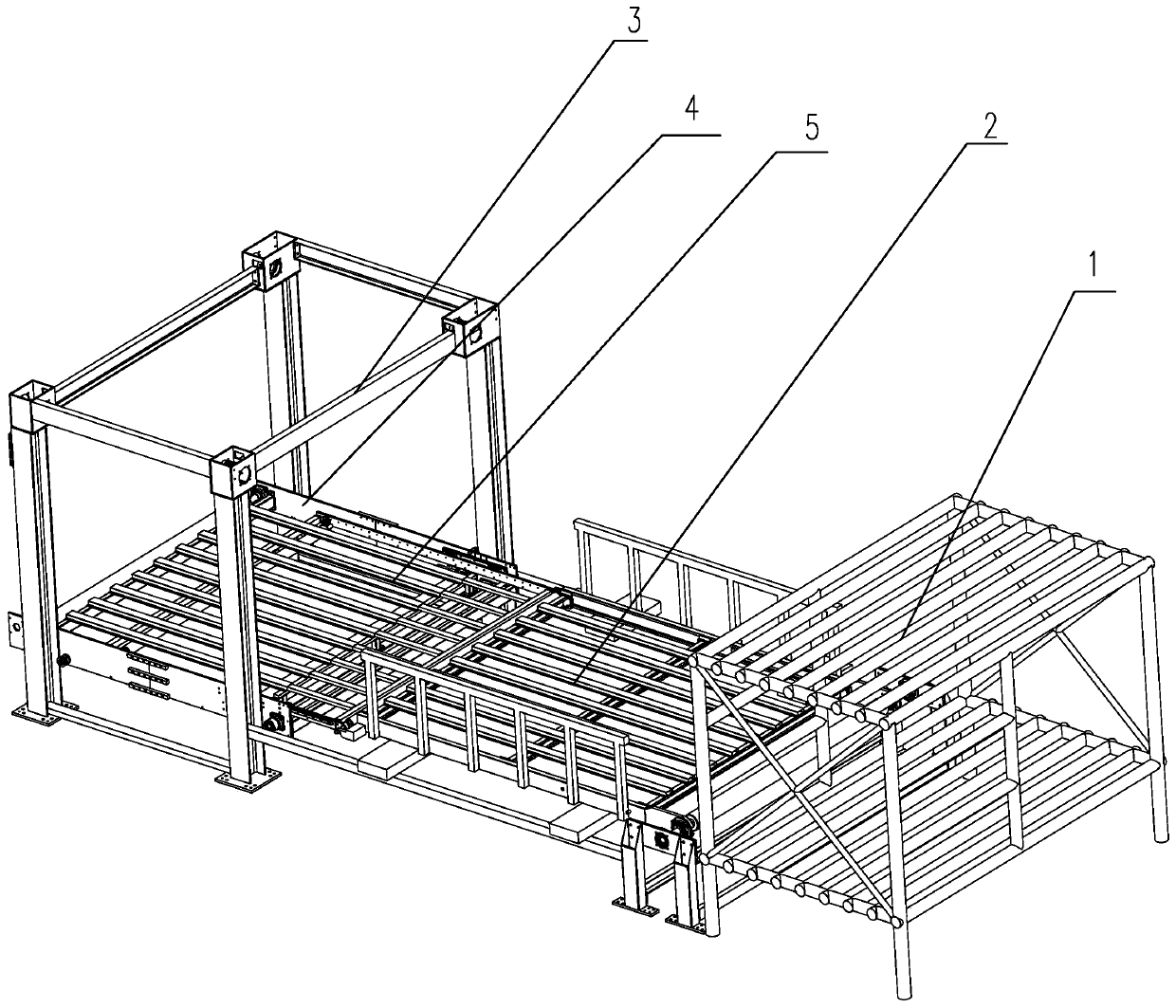

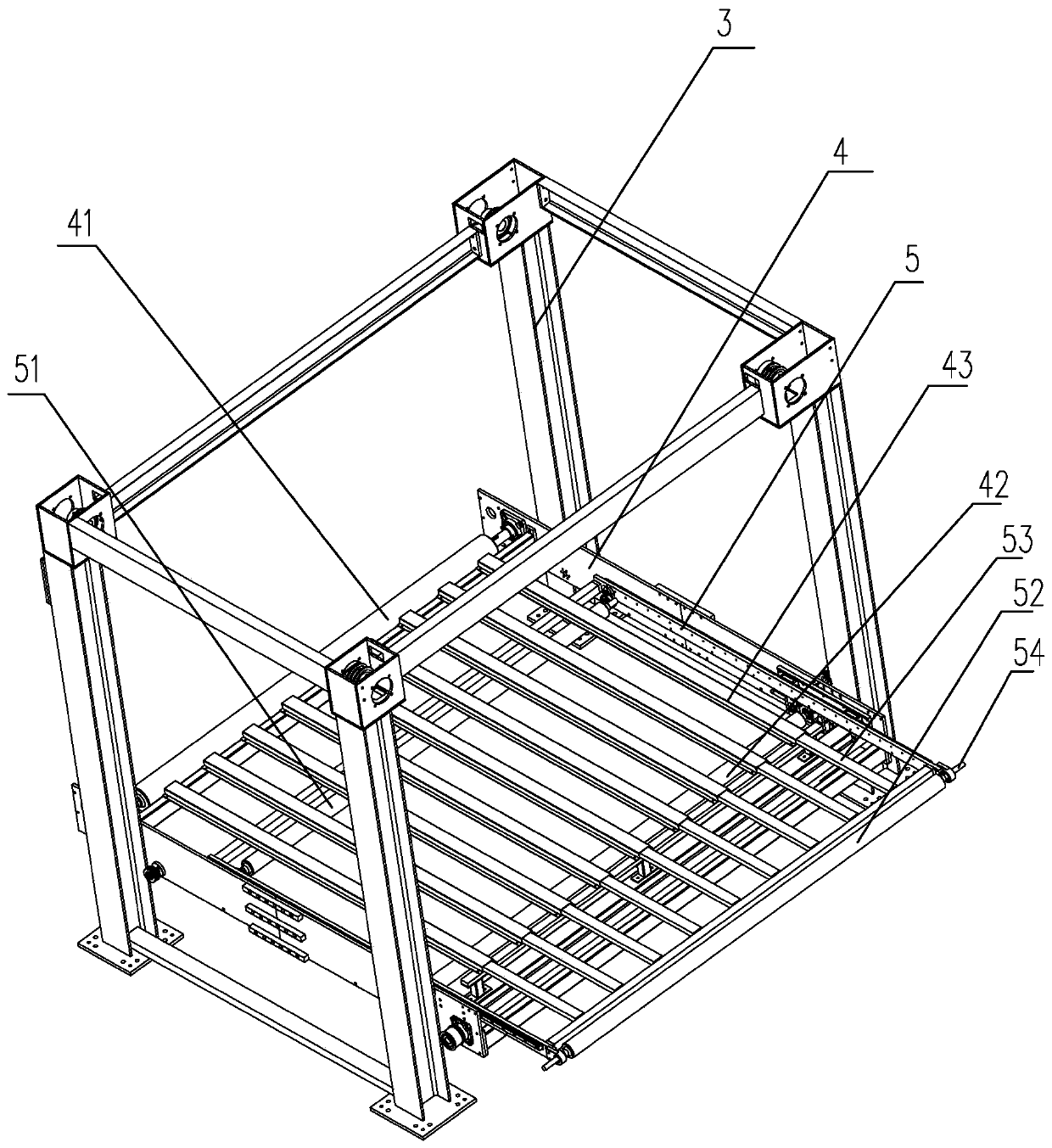

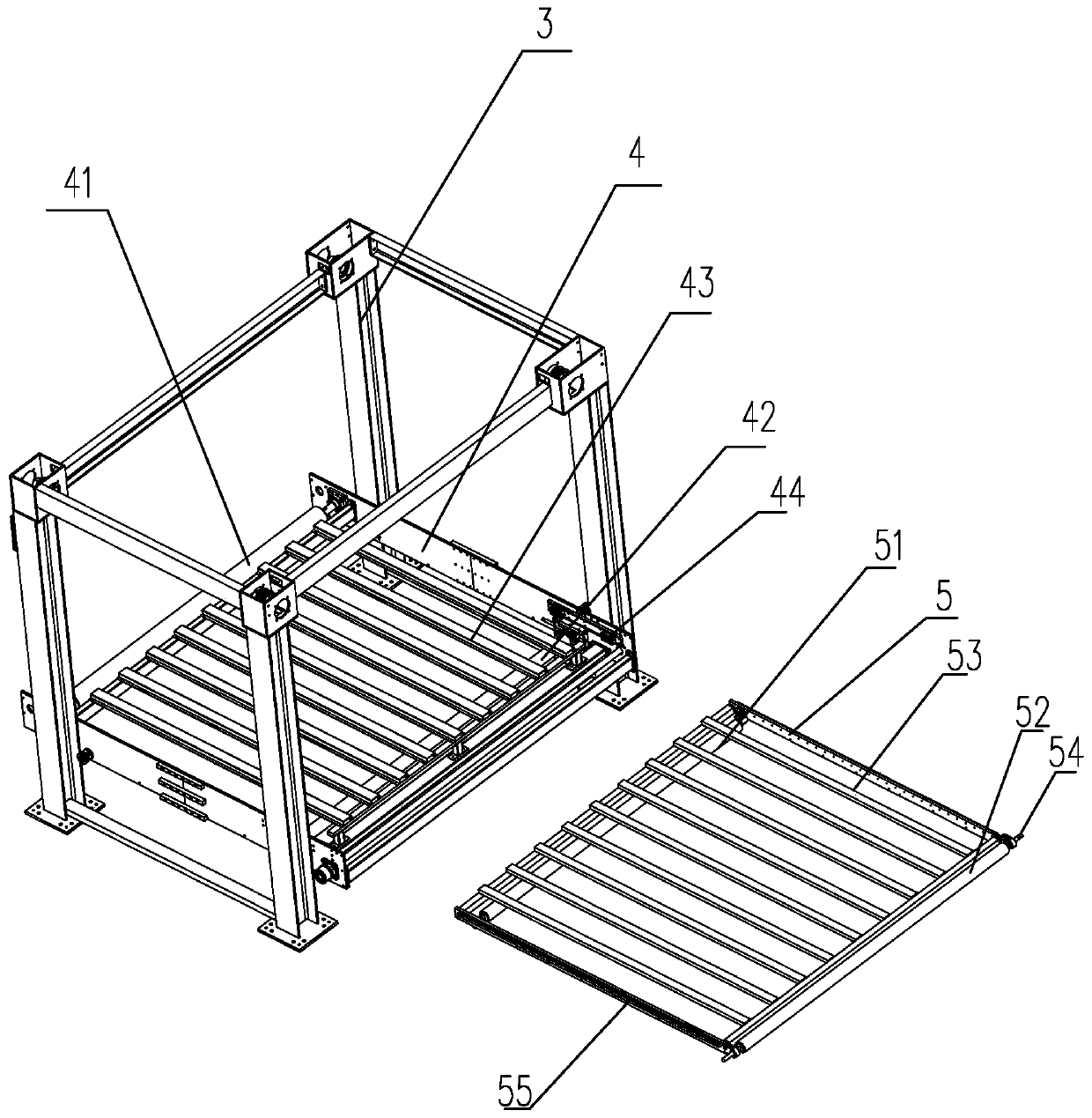

[0023] Depend on Figure 1 to Figure 5 Disclosed is a climbing frame with the function of lifting and conveying, comprising a main body support 1 and a lifting frame 3, a lifting passage is formed in the main body support 1, the lifting frame 3 is arranged in the lifting passage, and the lifting frame 3 is set There is a lifting platform 4 and a first driving member for driving the lifting platform 4 to slide along the height direction. The lifting platform 4 is provided with a conveying mechanism for transferring materials, and the lifting platform 4 is also provided with a sliding frame 5. A slideway 44 and a slider 55 are arranged between the sliding frame 5 and the side wall of the lifting platform 4, and the slideway 44 and the sliding block 55 slide and cooperate to form the sliding movement of the sliding frame 5 on the lifting platform 4. The lifting platform 4 is also provided with a second driving member for driving the sliding frame 5 to slide out of the lifting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com