Ultra-thin high-sliding-resistance surface layer of asphalt pavement and construction method thereof

A technology of asphalt pavement and construction method, which is applied in the direction of roads, roads, and on-site coagulation pavement, etc., can solve the problems of reduced driving safety, reduced use function of pavement surface, and attenuation of anti-skid performance, and achieves improved surface use. function, good road performance and structural characteristics, improve the effect of anti-skid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments.

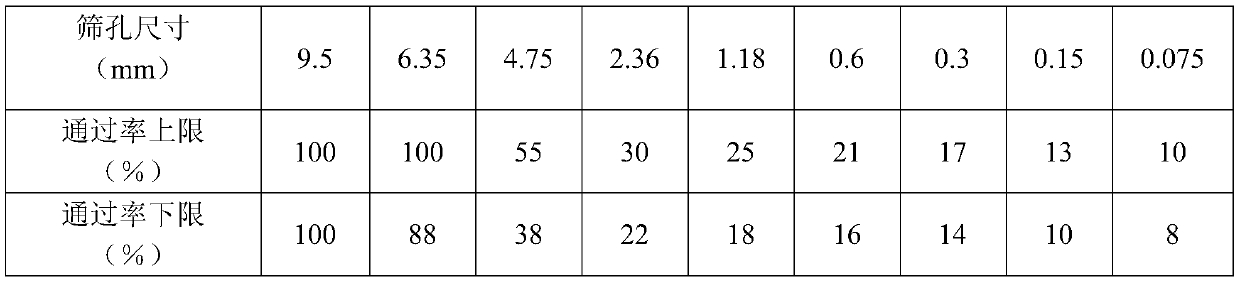

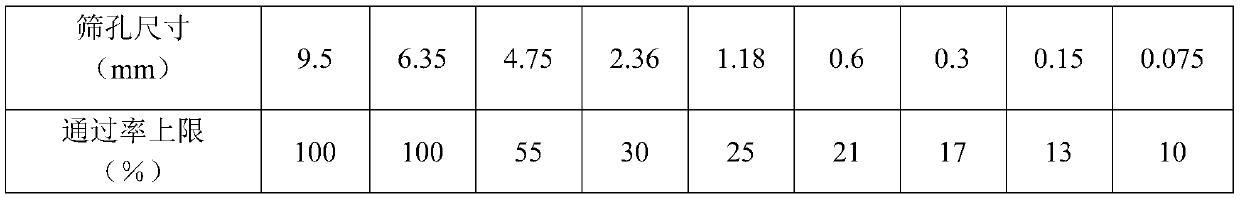

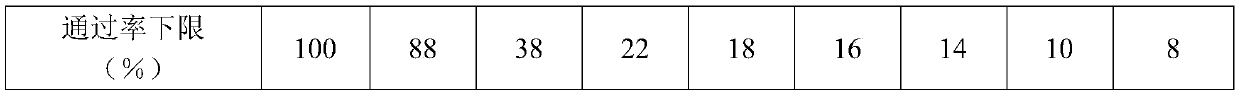

[0032] The ultra-thin and highly skid-resistant surface layer of the asphalt pavement in the present invention includes a wear layer and an adhesive layer, and the wear layer is bonded with the asphalt pavement through the adhesive layer to form a whole. The wearing layer adopts asphalt mastic macadam mixture with a nominal maximum particle size of 6.35mm. The gradation range is determined according to the aggregate volume parameters. Therefore, when calcined bauxite is used to replace part of limestone, bauxite should be used The same volume replaces the limestone, and the particle size of the replaced part is 4.75mm-6.35mm and 6.35mm-9.5mm.

[0033] The mineral material gradation range of the ultra-thin high-skid-resistant surface layer of the asphalt pavement of the present invention is shown in the following table.

[0034]

[0035] The technical character...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com