Cloth feeding mechanism of digital printing machine

A technology of a digital printing machine and a guiding mechanism, applied in the field of digital printing machines, can solve problems such as difficulty in controlling force balance, inconvenient adjustment of counterweights, inability to eliminate loose sticking, etc., to achieve compact structure, improve printing quality and structure. scientific compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

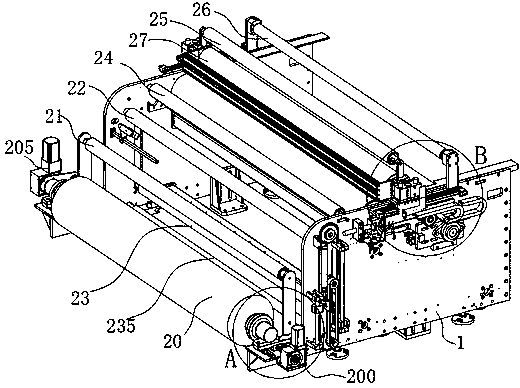

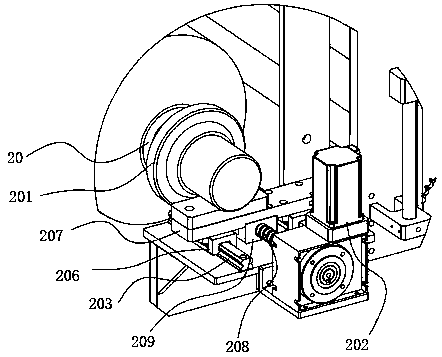

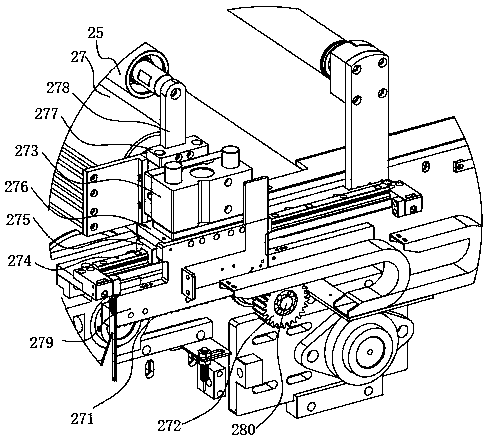

[0037] see Figure 1~Figure 13 The cloth loading mechanism of the digital printing machine preferably implemented in the present invention includes a frame 1, and an air expansion shaft 20 arranged on the frame 1, a large wrap angle roller 21, a cloth passing roller a22, a constant tension floating roller 23, a passing Cloth roller b24, cloth passing roller c25, moving roller 27, widening angle wrapping roller 26; the rear side of frame 1 is the cloth feeding side; it is characterized in that, the air expansion shaft 20, large roll wrapping angle roller 21, passing The cloth roller a22, the cloth passing roller b24, and the cloth passing roller c25 are arranged at intervals along the forward direction of the cloth; the constant tension floating roller 23 can be lowered between the cloth passing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com