Joint mounting equipment and connecting method of flexible pipe and joint

A technology for installing equipment and flexible pipes, which is applied in the field of fixtures and fixtures, can solve the problems of affecting the safety of operators, unguaranteed quality, and low pressing efficiency, and achieve the effects of simple and convenient operation, reducing the number of operators, and high pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

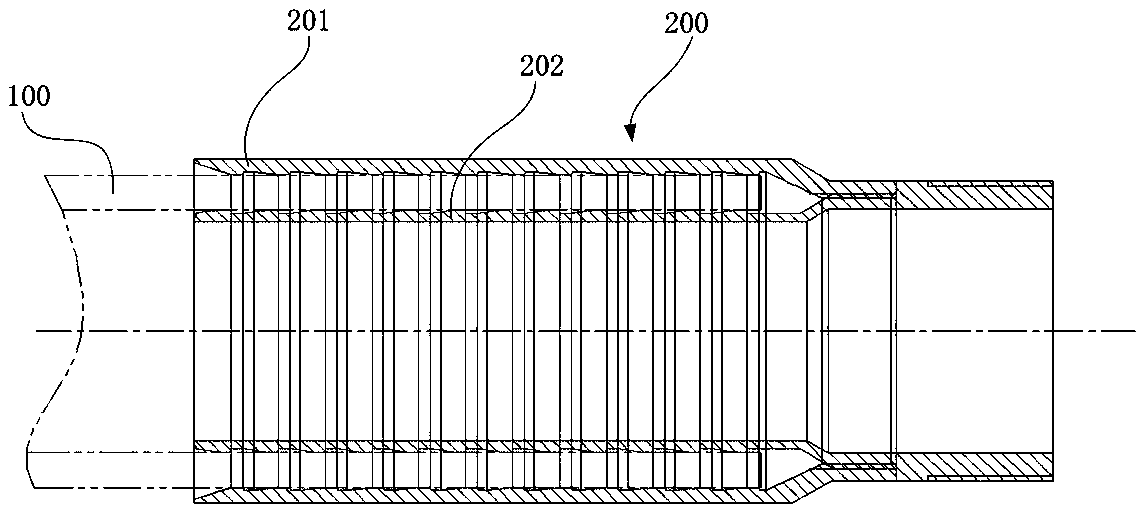

[0048] figure 1 Shown is a schematic diagram of the connection between the flexible pipe and the joint. The joint 200 has an inner pipe 202 and an outer pipe 201. The first end of the inner pipe 202 and the first end of the outer pipe 201 are connected correspondingly, such as threaded connection, etc. The flexible pipe 100 is connected from the joint. The second end of 200 is inserted between the inner tube 202 and the outer tube 201 .

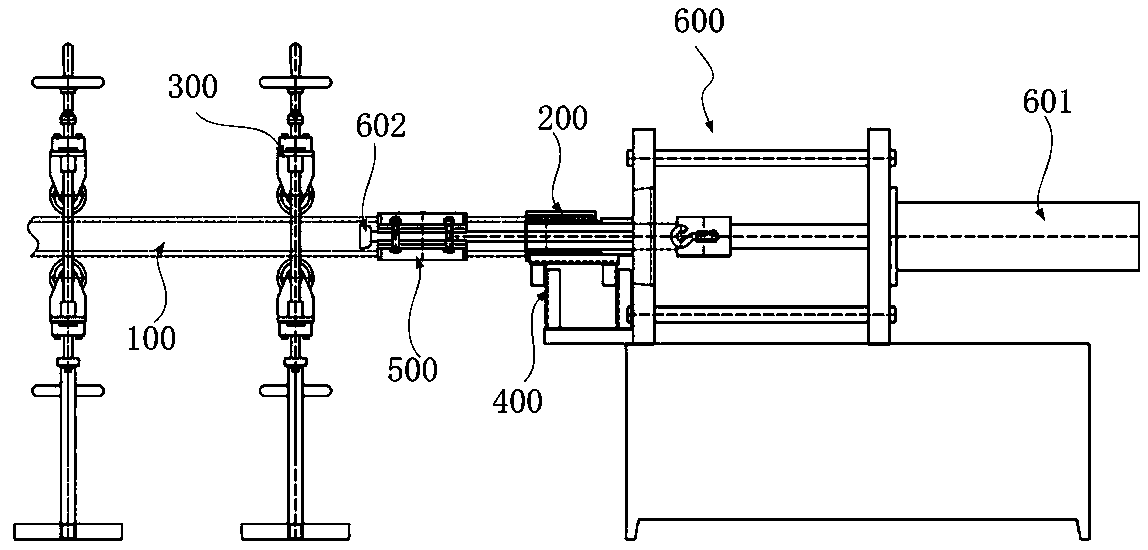

[0049] Such as figure 2 As shown, a joint installation device illustrated in this example is used for the auxiliary connection of the end of the flexible pipe 100 and the joint 200, wherein the joint 200 includes an inner tube 202 and an outer tube 201 whose ends are connected, and the inner tube 202 is connected to the outer tube 200. The tube 201 forms an annular cavity for accommodating the end of the flexible tube 100. The end of the flexible tube 100 is inserted into the annular cavity to be connected with the joint 200 and pressed tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com