Fixing equipment for solid wood floor paint spraying machining

A technology for fixing equipment and solid wood floors, applied in the direction of spraying devices, etc., can solve problems such as inconvenient fixing, and achieve the effects of enhancing structural stability, enhancing clamping bearing strength, and preventing fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

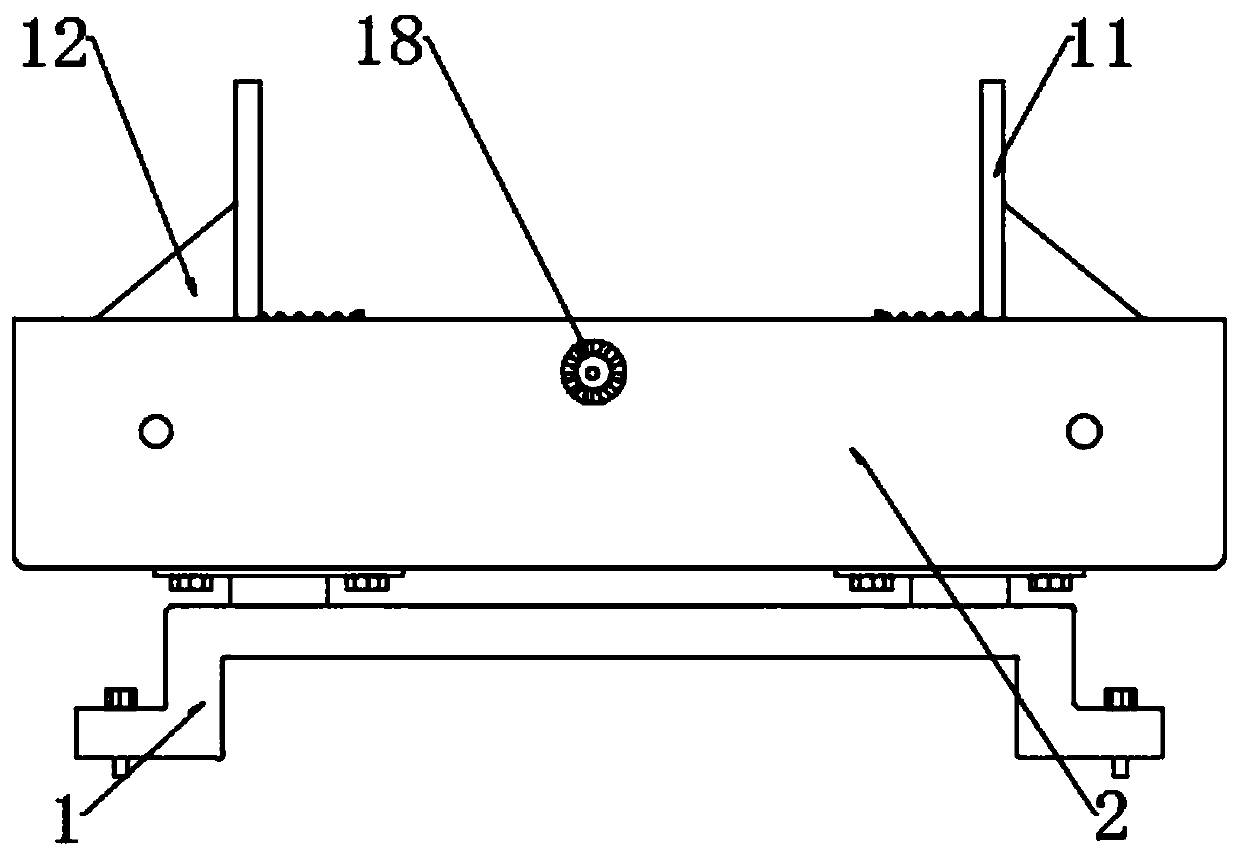

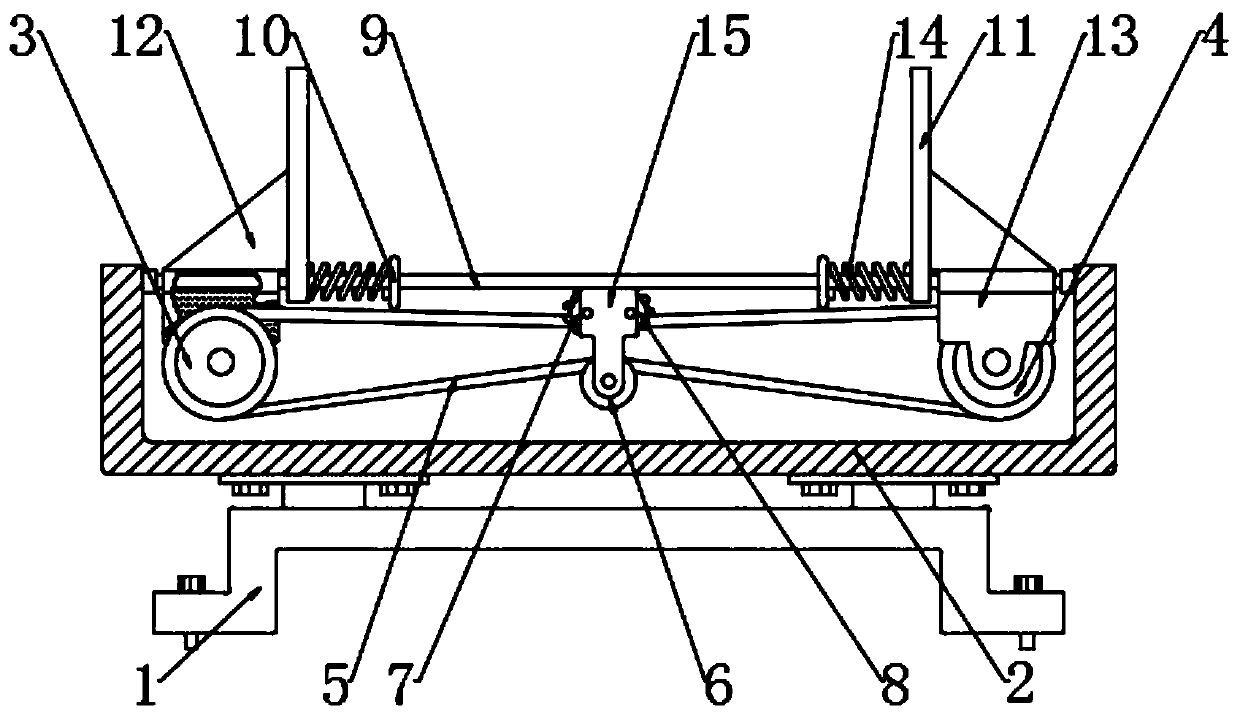

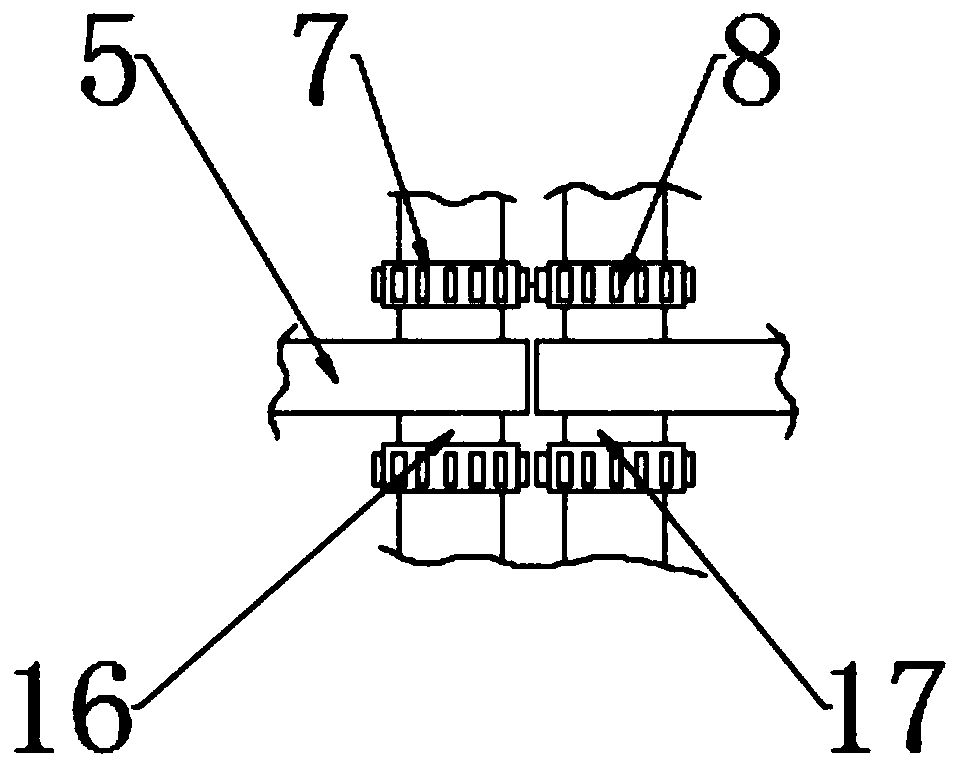

[0035] see Figure 1-3 , a kind of fixed equipment for solid wood floor painting processing, including a fixed seat 1, the fixed seat 1 is connected with a protective shell 2 through bolts, the inner top of the protective shell 2 is fixedly installed with a horizontally arranged connecting rod 9, and the two ends of the connecting rod 9 Both ends are slidably connected with a fixed frame 13, the top of the fixed frame 13 is fixedly connected with a clamping plate 11 through a rib plate 12, and the bottom ends of the two fixed frames 13 are respectively connected with a rotating wheel 3 and a rotating wheel 4 through rotating shafts. , the lower end surface of the center of the connecting rod 9 is fixedly equipped with a convex block 15, and the convex block 15 is connected with a winding roller one 16 and a winding roller two 17 through the rotation of the rotating shaft, and the winding roller one and the winding roller two 17 The rotation of the wire rope 5 is contracted or ...

Embodiment 2

[0037] see Figure 1-3 , a kind of fixed equipment for solid wood floor painting processing, including a fixed seat 1, the fixed seat 1 is connected with a protective shell 2 through bolts, the inner top of the protective shell 2 is fixedly installed with a horizontally arranged connecting rod 9, and the two ends of the connecting rod 9 Both ends are slidingly connected with a fixed frame 13, and the top of the fixed frame 13 is fixedly connected with a clamping plate 11 through a rib plate 12. The shape of the rib plate 12 is set as a triangle, and the principle of strong triangular stability is used to strengthen the clamping plate 11. Bearing capacity, the bottom ends of the two fixed mounts 13 are connected to the rotating wheel one 3 and the rotating wheel two 4 through the rotating shaft respectively, and the lower end surface of the center of the connecting rod 9 is fixedly equipped with a convex block 15, and the convex block 15 passes through the rotating shaft. The f...

Embodiment 3

[0039] see Figure 1-2 , a kind of fixed equipment for solid wood floor painting processing, including a fixed seat 1, the fixed seat 1 is connected with a protective shell 2 through bolts, the inner top of the protective shell 2 is fixedly installed with a horizontally arranged connecting rod 9, and the two ends of the connecting rod 9 Both ends are slidably connected with a fixed frame 13, the top of the fixed frame 13 is fixedly connected with a clamping plate 11 through a rib plate 12, and the bottom ends of the two fixed frames 13 are respectively connected with a rotating wheel 3 and a rotating wheel 4 through rotating shafts. , the rotating wheel one 3 and the rotating wheel two 4 are symmetrically distributed, and the lower end surface of the center of the connecting rod 9 is fixedly equipped with a convex block 15, and the convex block 15 is connected with a winding roller one 16 and a winding roller two through rotating shaft rotation. 17. The rotating shaft of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com