Toy glue bonding fixing device

A technology for fixing devices and toys, which is applied to devices for coating liquid on the surface, connecting components, mechanical equipment, etc. It can solve the problems of toy displacement, affecting the bonding and fixing position, and insufficient clamping and fixing strength of bonding toys, etc., and achieves improvement. Accuracy, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

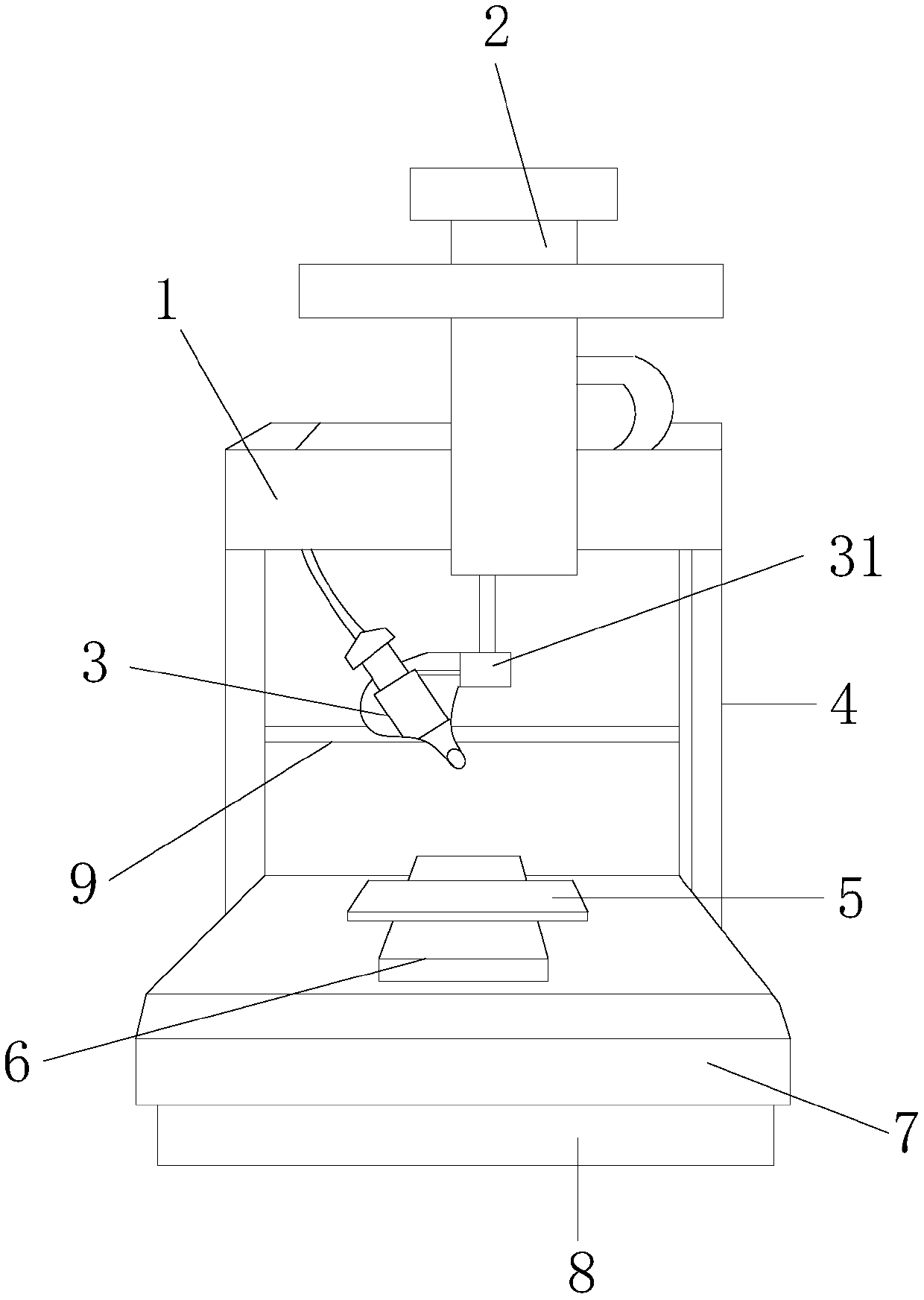

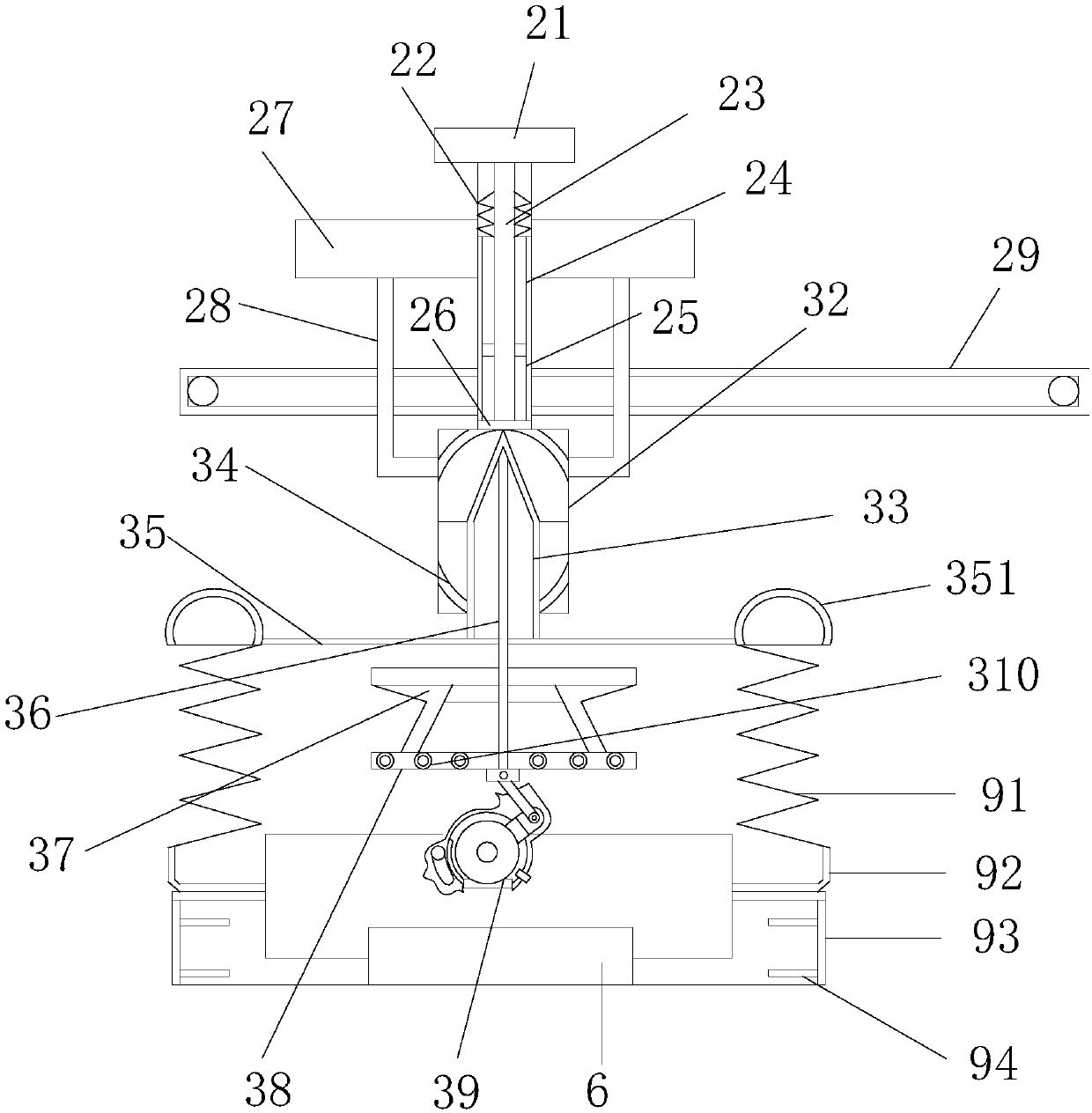

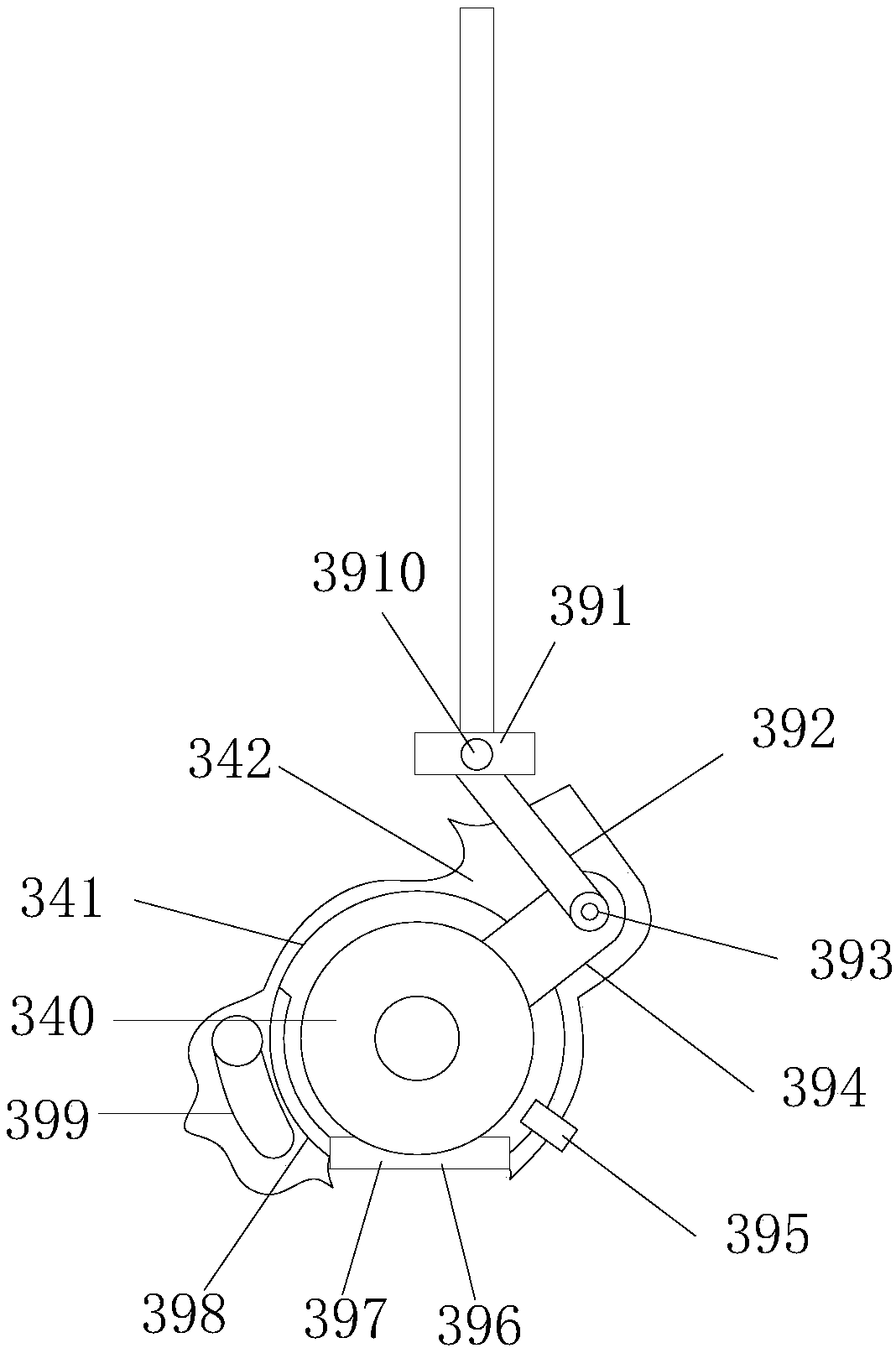

[0026] see Figure 1 to Figure 6, the present invention provides a toy adhesive fixing device, the structure of which includes a fixed beam 1, a glue controller 2, an automatic glue application mechanism 3, a frame 4, a toy installation adhesive board 5, a sliding seat 6, a work surface 7, Damping base 8, for the whole frame 9, the glue controller 2 is movably installed on the fixed beam 1 and is perpendicular to the fixed beam 1, and the left and right ends of the fixed beam 1 are welded and perpendicular to the frame 4, The frame 4 is fixedly connected to the work surface 7, the slide seat 6 is installed above the work surface 7 and is parallel to the work surface 7, and the toy is installed on the top of the slide seat 6. The bonding board 5 and the sliding seat 6 are perpendicular to each other, the lower end of the worktable 7 and the shock-absorbing base 8 are an integrated structure, the automatic gluing mechanism 3 is installed under the gluing controller 2, and the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com