Pressure limiting valve assembly and cooking utensil

A technology of cooking utensils and pressure limiting valves, which is applied in the field of pressure limiting valve components and cooking utensils, can solve the problems of poor sealing, overflow of soup in the pressure cooker, waste of energy, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

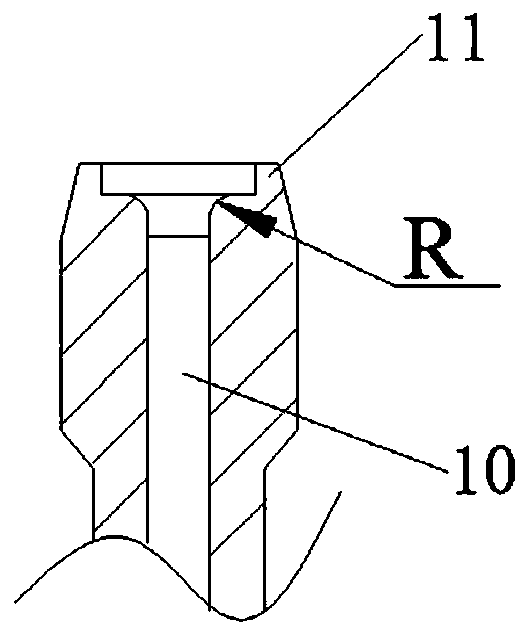

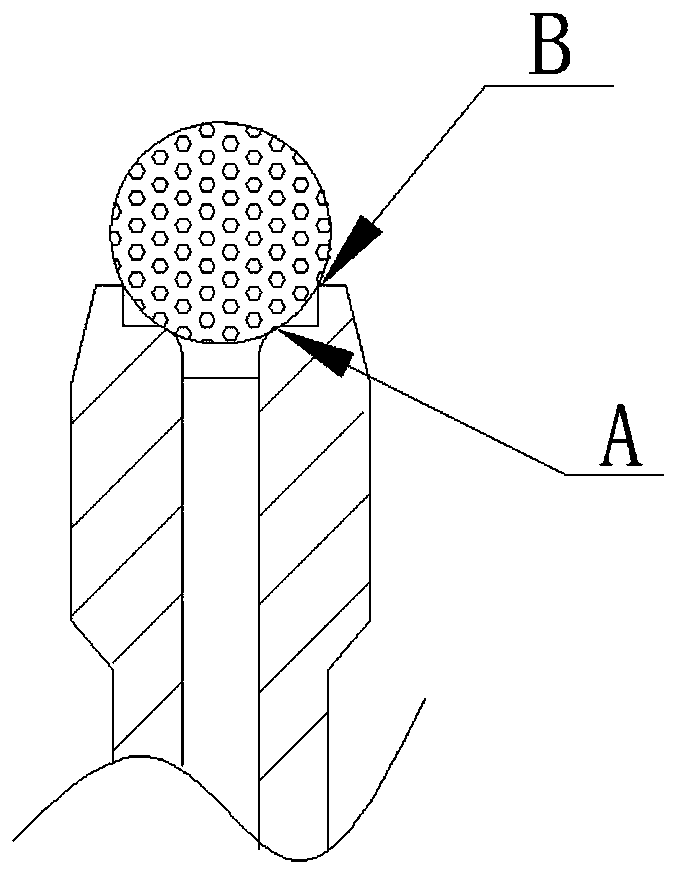

[0029] like figure 1 As shown, the pressure limiting valve assembly of this embodiment includes an exhaust pipe 1 and a pressure limiting valve 2, and the pressure limiting valve 2 is installed on the exhaust pipe 1.

[0030] Specifically, such as figure 1 As shown, the pressure limiting valve 2 includes a valve body 21 and a spherical valve core 22 , and the spherical valve core 22 is connected to the inner chamber of the valve body 21 through a connecting piece 23 . Wherein, the connecting piece 23 and the spherical valve core 22 can be connected through a necking structure, and the necking refers to a forming process of shrinking the mouth of a preformed cylinder or pipe blank through a necking die. In addition, the connection method between the connecting piece 23 and the spherical valve core 22 can also refer to the connection method in the prior art, such as welding, crimping, overmolding or integral molding, which will not be repeated here.

[0031] like figure 2 As...

Embodiment 2

[0041] The difference between the pressure limiting valve assembly of this embodiment and Embodiment 1 is:

[0042] The inner wall of the first step is chamfered, and the chamfered surface intersects with the spherical surface of the spherical valve core to form a line to form the first sealing structure; other structures can refer to Embodiment 1.

[0043] In the cooking appliance of this embodiment, the pressure limiting valve assembly it includes is the pressure limiting valve assembly of this embodiment; other structures can refer to Embodiment 1.

[0044] The pressure-limiting valve assembly and the cooking utensil of this embodiment can also realize the breathing exhaust effect and realize structural diversification.

Embodiment 3

[0046] The difference between the pressure limiting valve assembly of this embodiment and Embodiment 1 is:

[0047] The right angle of the mouth of the first step intersects with the spherical surface of the spherical valve core to form a line to form the first sealing structure; the inner diameter of the second step is larger than that of the first step, and other structures can refer to Embodiment 1.

[0048] In the cooking appliance of this embodiment, the pressure limiting valve assembly it includes is the pressure limiting valve assembly of this embodiment; other structures can refer to Embodiment 1.

[0049] The pressure-limiting valve assembly and the cooking utensil of this embodiment can also realize the breathing exhaust effect and realize structural diversification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com