Seabuckthom fruit dextrose candy preparation method

A technology of seabuckthorn tableting and seabuckthorn fruit powder, which is applied in the fields of confectionery, confectionery industry, and the function of food ingredients, etc., can solve the problems of low yield of production process, bad taste, and difficulty in arousing consumers' interest, etc. Sweet and sour, good for health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

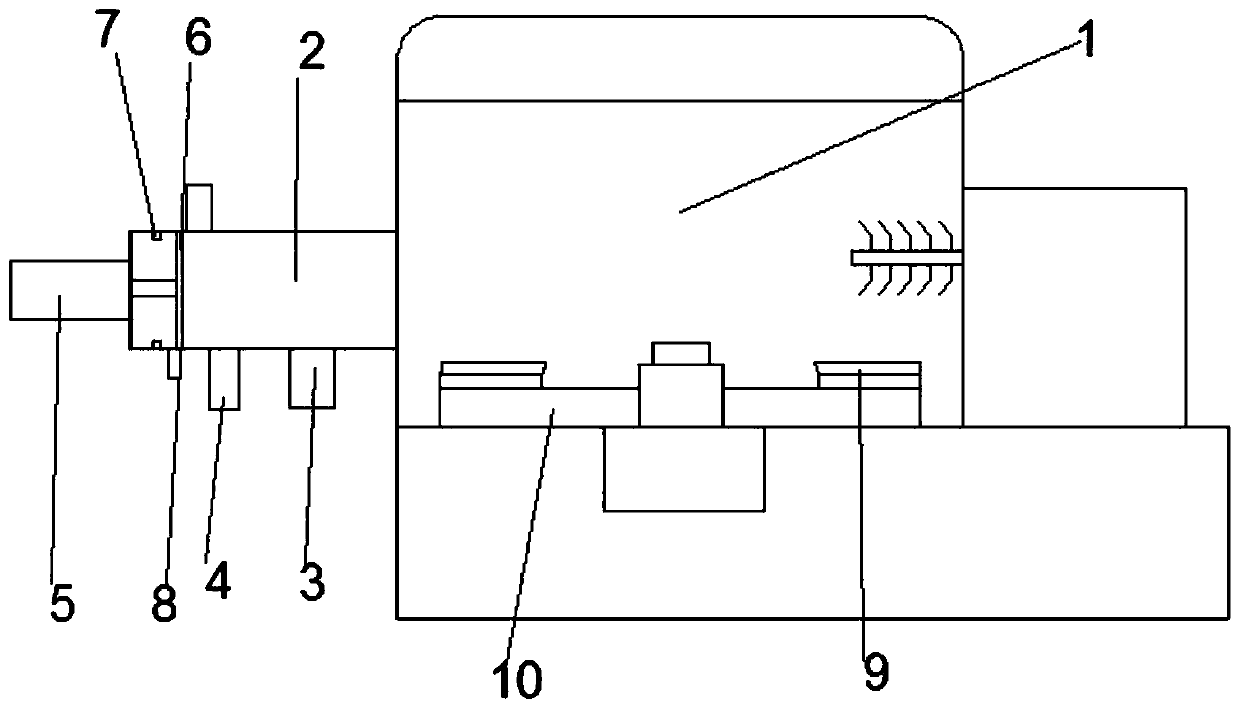

[0023] Such as figure 1 Shown, the present invention is a kind of preparation method of seabuckthorn compressed tablet candy, comprises the following steps:

[0024] 1) Weighing: each piece of candy weighs the raw materials according to the following proportions, sea buckthorn fruit powder 150-250mg, acerola cherry powder 8-12mg, sorbitol 300-350mg, lactose 180-210mg, citric acid 50-70mg, carbonic acid Sodium hydrogen 35-50mg, aspartame 0.3-0.8mg, magnesium stearate 7-12mg;

[0025] 2) sieving: all materials are screened through 40 mesh sieve and 50 mesh sieve respectively, large particles are removed, and fine powder is left for subsequent use;

[0026] 3) Premixing: add sea buckthorn fruit powder, acerola cherry powder, sorbitol, and lactose into the wet granulator, set the mixing speed to 100-200r / min, and the speed of the granulating knife: 500-1000r / min to perform premixing 2 -3min;

[0027] 4) Wet granulation: add ethanol with a concentration of 70-95% to the premixed...

Embodiment 1

[0035] A preparation method of seabuckthorn compressed candy, comprising the following steps:

[0036] 1) Weighing: each piece of candy weighs the raw materials according to the following proportions, sea buckthorn fruit powder 200mg, acerola cherry powder 10mg, sorbitol 339.5mg, lactose 200mg, xylitol 140mg, citric acid 60mg, sodium bicarbonate 40mg, Aspartame 0.5mg, magnesium stearate 10mg;

[0037] 2) sieving: all materials are screened through 40 mesh sieve and 50 mesh sieve respectively, large particles are removed, and fine powder is left for subsequent use;

[0038] 3) Premixing: Add sea buckthorn fruit powder, acerola cherry powder, sorbitol, xylitol, and lactose into the wet granulator, set the mixing speed to 100-200r / min, and the granulation knife speed: 500-1000r / min, Premix for 2-3 minutes;

[0039] 4) Wet granulation: add ethanol with a concentration of 70-95% to the premixed raw materials and granulate for 3-5 minutes to obtain soft materials, and wet granulat...

example 1

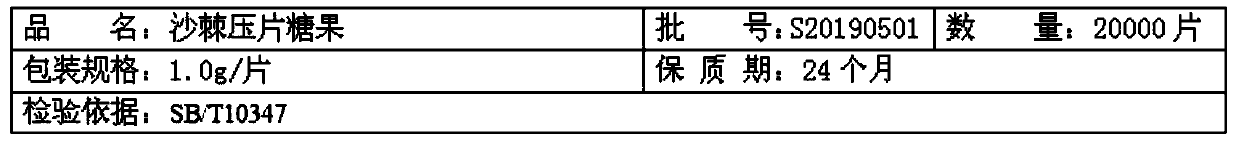

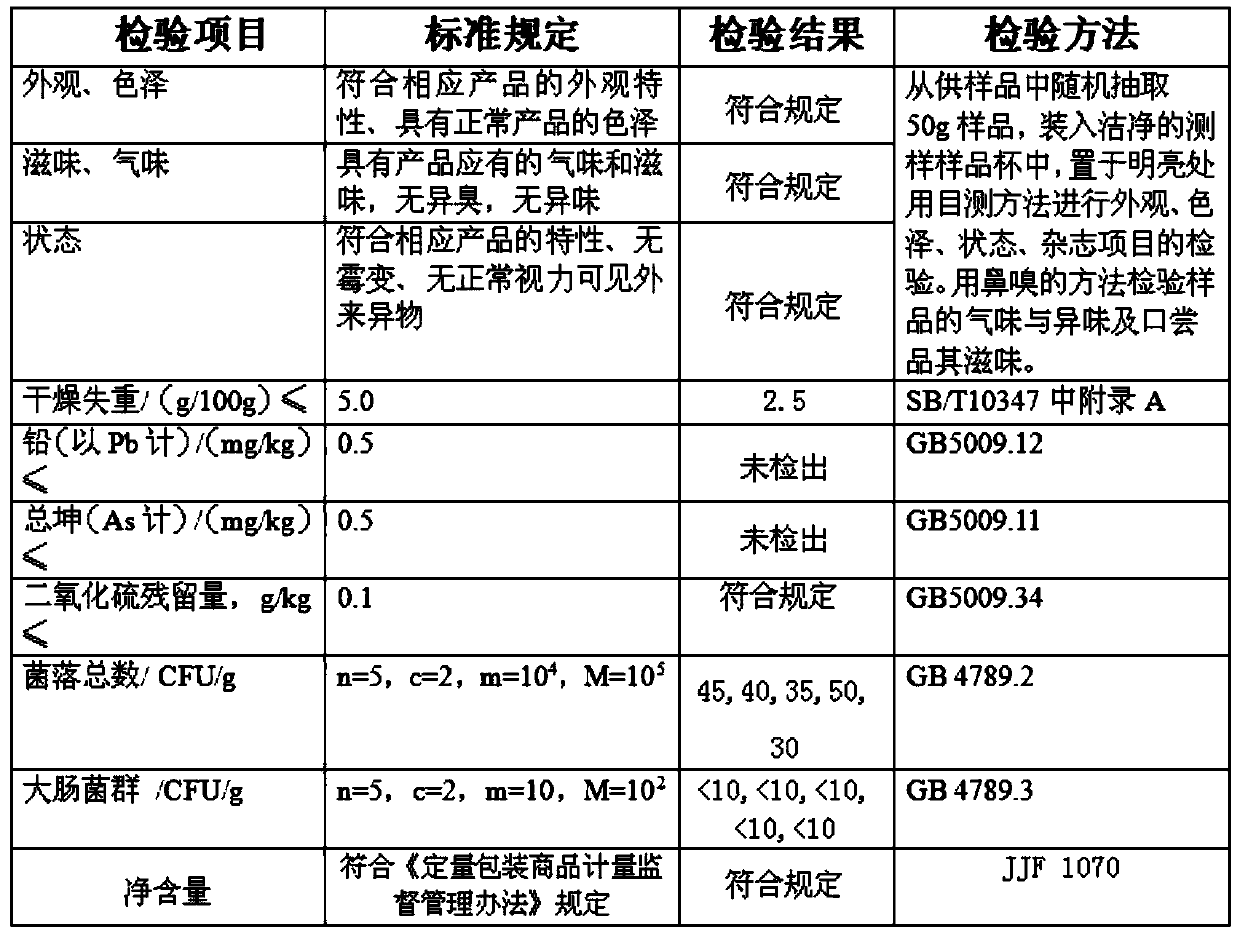

[0044] Example 1 formula 20000 tablets

[0045] serial number Material name Dosage per tablet mg / tablet 20000 pieces (kg) Remark 1. Sea buckthorn fruit powder 200 4 2. Acerola Cherry Powder 10 0.2 3. Sorbitol 339.5 6.79 4. lactose 200 4 5. Xylitol 140 2.8 6. citric acid 60 1.2 7. sodium bicarbonate 40 0.8 8. Aspartame (with phenylalanine) 0.5 0.01 9. Magnesium stearate 10 0.2 10. total 1000 20

[0046] Experimental data:

[0047] product name Sea Buckthorn Tablet Candy Sea Buckthorn Tablet Candy Sea Buckthorn Tablet Candy Serial Number S20190501 S20190502 S20190503 Batch (piece) 20000 20000 20000 Theoretical particle yield (kg) 20 20 20 Actual particle yield (kg) 19.56 19.42 19.69 Actual particle yield (%) 97.8 97.1 98.4 Theoretical finished product yield (piece) 20000 20000 20000 Actual fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com