An intelligent management system and method for electric vehicle battery power and temperature

A technology of battery temperature and battery power, applied in electric vehicles, battery/fuel cell control devices, vehicle energy storage, etc., can solve problems such as side reactions and damage to battery chemical balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

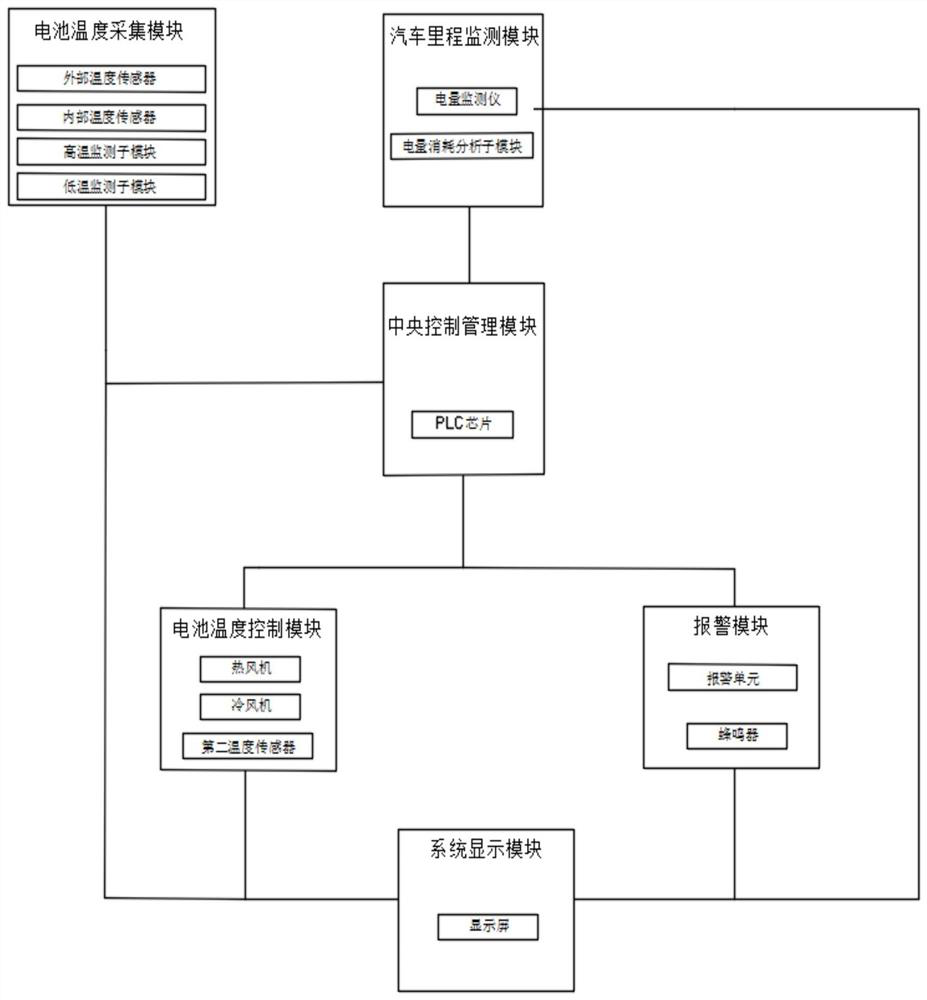

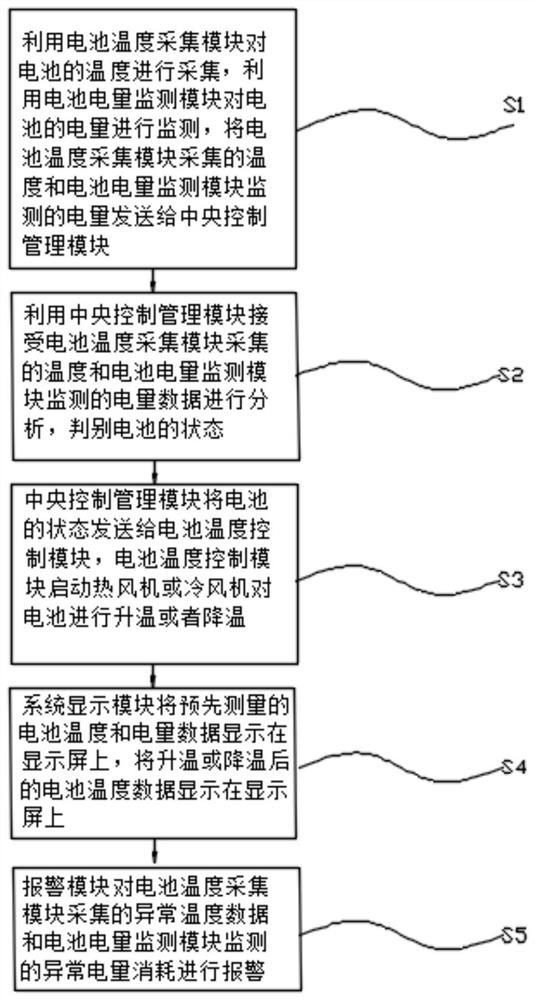

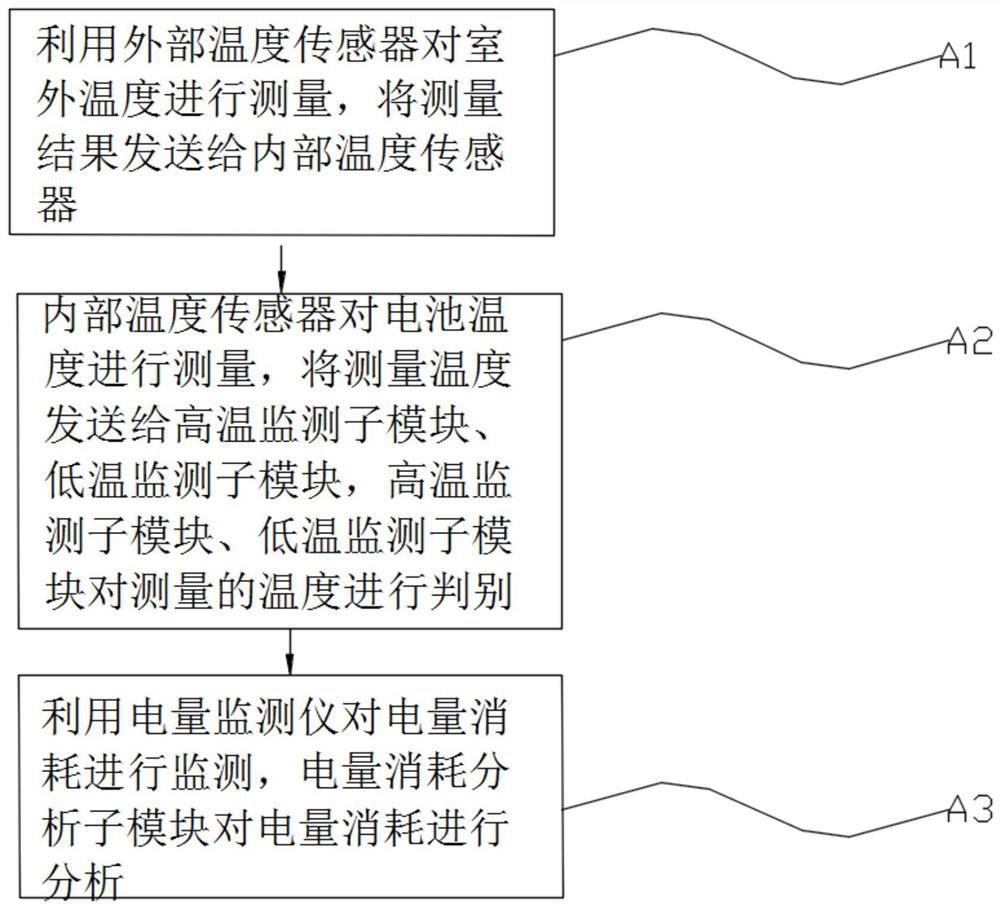

Method used

Image

Examples

Embodiment 1

[0072] Example 1: Restricted conditions: the monitoring time of the internal temperature sensor and the electricity monitor is 11:00, 12:00, 13:00, 14:00, 15:00, and the temperature collected by the internal temperature sensor is 22 ℃, 23.1℃, 24.5℃, 24.9℃, 25℃, the battery power is 95.6Q, 94Q, 89Q, 87.3Q, 85Q, extract the maximum value of the internal temperature sensor temperature of 25℃ and the minimum value of 22℃, extract the The maximum value of the monitored power is 95.6Q and the minimum value is 85Q, according to the formula:

[0073]

[0074] Calculated:

[0075]

[0076] Therefore, the calculated temperature collected by the internal temperature sensor and the power monitored by the power monitor satisfy the above formulas, and the central control management module defaults the battery temperature and power consumption to a normal state, and sends the measurement data of the internal temperature sensor to the battery temperature control module After temperatur...

Embodiment 2

[0077] Example 2: Restricted conditions: the monitoring time of the internal temperature sensor and the electricity monitor is 8:00, 9:30, 10:00, 11:30, 12:00, and the temperature collected by the internal temperature sensor is 35 ℃, 34.1℃, 25.3℃, 22.9℃, 20.3℃, the battery power is 98.7Q, 87Q, 79.1Q, 63.5Q, 51Q, extract the maximum value of the internal temperature sensor temperature 35℃ and the minimum value 20.3℃, extract the gas monitor The maximum value of the monitored electricity is 98.7Q and the minimum value is 51Q, according to the formula:

[0078]

[0079] Calculated:

[0080]

[0081] Therefore, the calculated temperature collected by the internal temperature sensor and the power monitored by the power monitor do not meet the above formulas, and the central control management module determines that the battery temperature and power consumption are abnormal, and sends the measurement data of the internal temperature sensor to the battery temperature control. ...

Embodiment 3

[0082] Example 3: Restricted conditions: the monitoring time of the internal temperature sensor and the electricity monitor is 8:00, 11:00, 14:00, 17:00, 20:00, and the temperature collected by the internal temperature sensor is 20.2 ℃, 22.3℃, 23.8℃, 28℃, 32.7℃, the battery power is 87Q, 81Q, 72.5Q, 61.3Q, 49.7Q, extract the maximum value of the internal temperature sensor temperature 32.7℃ and the minimum value 20.2℃, extract the power monitor The maximum value of the monitored electricity is 83Q and the minimum value is 49.7Q, according to the formula:

[0083] Calculated:

[0084]

[0085] Therefore, the calculated temperature collected by the internal temperature sensor and the power monitored by the power monitor do not meet the above formulas, and the central control management module determines that the battery temperature and power consumption are abnormal, and sends the measurement data of the internal temperature sensor to the battery temperature control. The mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com