Multi-cavity sandwich type micro-perforated plate silencing structure

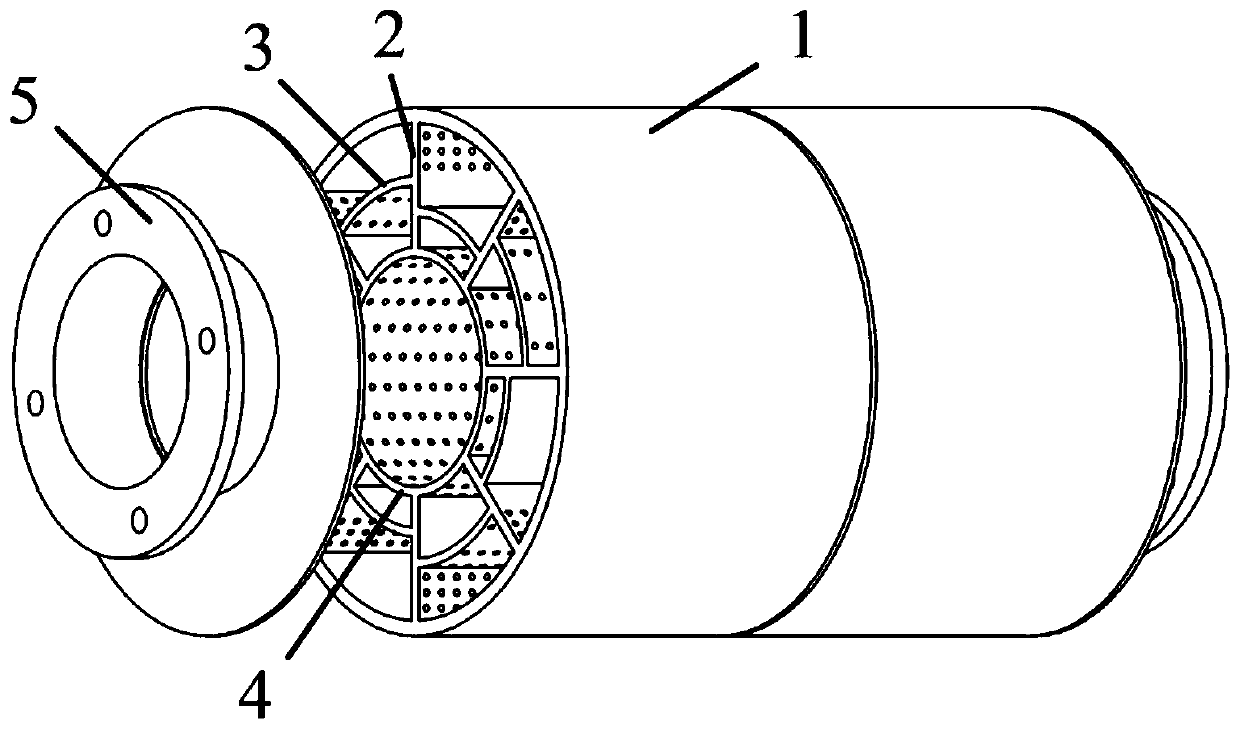

A technology of micro-perforated plates and perforated plates, which is applied in the direction of sound-generating devices and instruments, can solve the problems of insufficient sound-absorbing ability in the middle and high-frequency bands, and insufficient structural strength of micro-perforated plate sound-absorbing structures, and achieve good structural mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

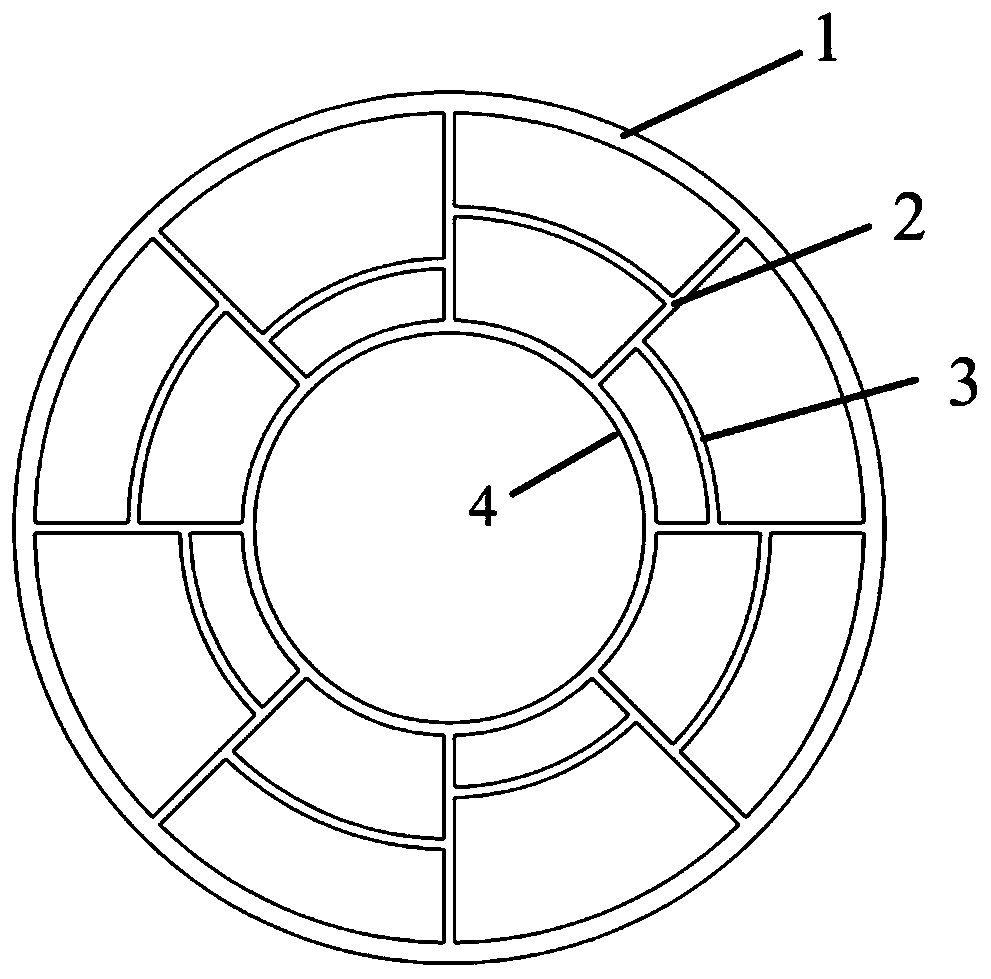

Embodiment 1

[0052] Two multi-cavity sandwich micro-perforated plate sound-absorbing structures are connected in series and have the same structural parameters. The thickness of the micro-perforated plate is 0.45mm, the perforation diameter is 0.4mm, and the perforation rate is 4%. mm, the perforation rate is 3.7%, the thickness of the unperforated sandwich panel is 0.4mm, the thickness of the shell is 2mm, the thickness of the partition is 1.5mm, the number of partitions is 6, the perforation rate of the partition area with micro-perforation is 4%, the diameter of the perforation 0.7mm, the diameter of the micro-perforated plate is 40mm, the cavity depth of the annular resonant cavity between the shell and the micro-perforated plate is 60mm, and the radii of curvature of the four sandwich plates with micro-perforated plates are 55mm, 55mm, 60mm, 60mm respectively, without perforation The radii of curvature of the two sandwich panels to be processed are 50mm and 50mm respectively, and the l...

Embodiment 2

[0054] The remaining parameters remain unchanged, only the number of partitions is changed to 8, the curvature radii of the 6 sandwich panels with micro-perforations are 50mm, 50mm, 55mm, 55mm, 60mm, and 60mm, and the curvature of the 2 sandwich panels without perforation The radii are 50mm and 50mm respectively.

Embodiment 3

[0056] The other parameters remain unchanged, only the number of partitions is changed to 10, the radii of curvature of the 8 sandwich panels with micro-perforations are 45mm, 45mm, 50mm, 50mm, 55mm, 55mm, 60mm, 60mm, and the 2 panels without perforation The radii of curvature of the sandwich panels are 50mm and 50mm respectively.

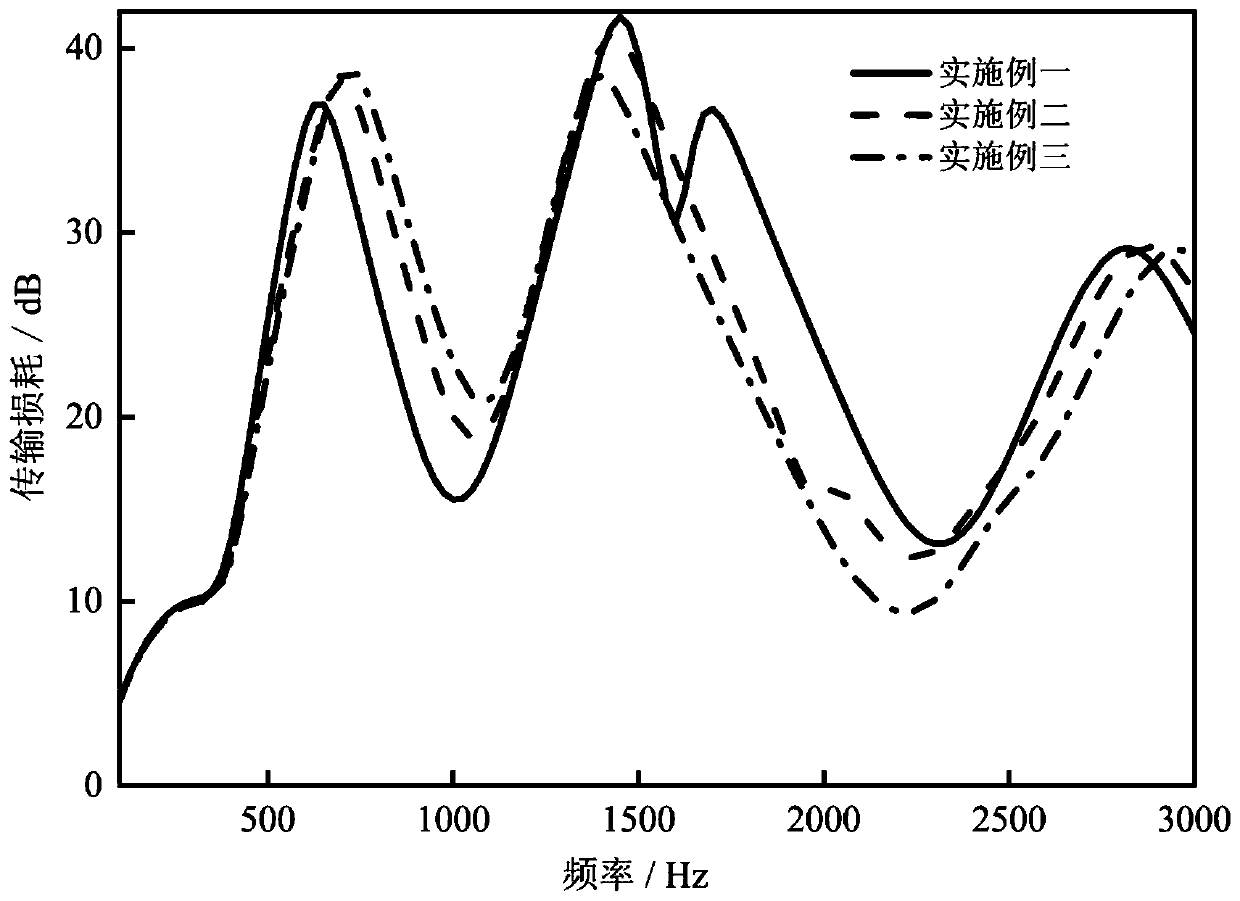

[0057] Adopt above-mentioned material and structure dimension to carry out numerical simulation, the result that provides embodiment is as follows:

[0058] see image 3 , is a schematic diagram of transmission loss in the range of 100-3000 Hz for three embodiments of a multi-cavity sandwich micro-perforated plate sound attenuation structure.

[0059] It can be seen from the figure that the average transmission loss of Embodiment 1 reaches 23.3dB within 100-1500Hz, and the average transmission loss within 1500-3000Hz reaches 24.7dB.

[0060] In Example 2, the average transmission loss within 100-1500 Hz reaches 24.6 dB, and the average transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com