Circulating water-cooled pressure test device

A technology of pressure testing and circulating water cooling, which is applied in measuring devices, cooling/ventilation/heating transformation, instruments, etc., can solve the problems of poor heat dissipation of the data acquisition and processing host, affect the overall operation stability of the structure, and high temperature, and achieve the cooling effect Excellent, good sealing, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

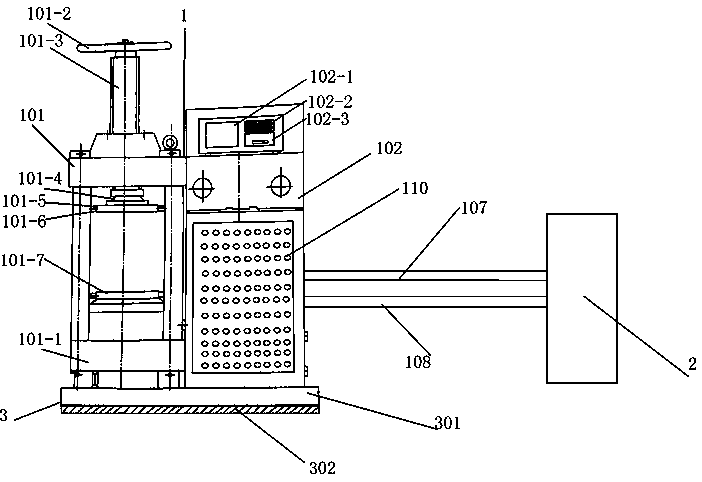

[0015] Embodiment 1: A circulating water-cooled pressure test device includes a pressure testing machine body 1 and a cooling circulation device 2. One end of the pressure testing machine body 1 is provided with a cooling circulation device 2 and is connected by a delivery pipeline. The pressure test The machine body 1 includes a test body 101 and a data collection and processing box 102 located at one end of the test body. The data collection and processing box 102 is equipped with a data collection and processing host 103, and the outer end of the data acquisition and processing host 103 is equipped with a Cooling liquid pipeline chamber groove 104, described cooling liquid pipeline chamber groove 104 is equipped with sealing partition 105, and described sealing partition 105 is provided with connecting opening 106 at both upper and lower ends, and described connecting opening 106 is connected with conveying pipeline respectively 107 is connected with the output pipeline 108,...

Embodiment 2

[0016] Embodiment 2: The bottom end of the pressure testing machine body 1 is fixedly installed on the anti-slip and shock-absorbing assembly 3. The anti-slip and shock-absorbing assembly 3 includes a fixed base 301 and an anti-slip and shock-absorbing layer 302. The anti-slip and shock-absorbing layer 302 is arranged on a fixed The bottom of the base 301 and the anti-skid shock-absorbing layer 302 are integrally formed by injection molding of polyurethane rubber, and the rest of the technical solutions are the same as those in the first embodiment.

Embodiment 3

[0017] Embodiment 3: The outer surface of the data collection and processing box 102 is evenly provided with several heat dissipation openings 110 , and the rest of the technical solutions are the same as those of Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com