High-flow fuel fine filter assembly

A fine filter, large flow technology, applied in the direction of machine/engine, liquid fuel feeder, engine components, etc., can solve the problems of increasing fuel flow and decreasing fuel lubrication performance, and achieve the effect of meeting demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

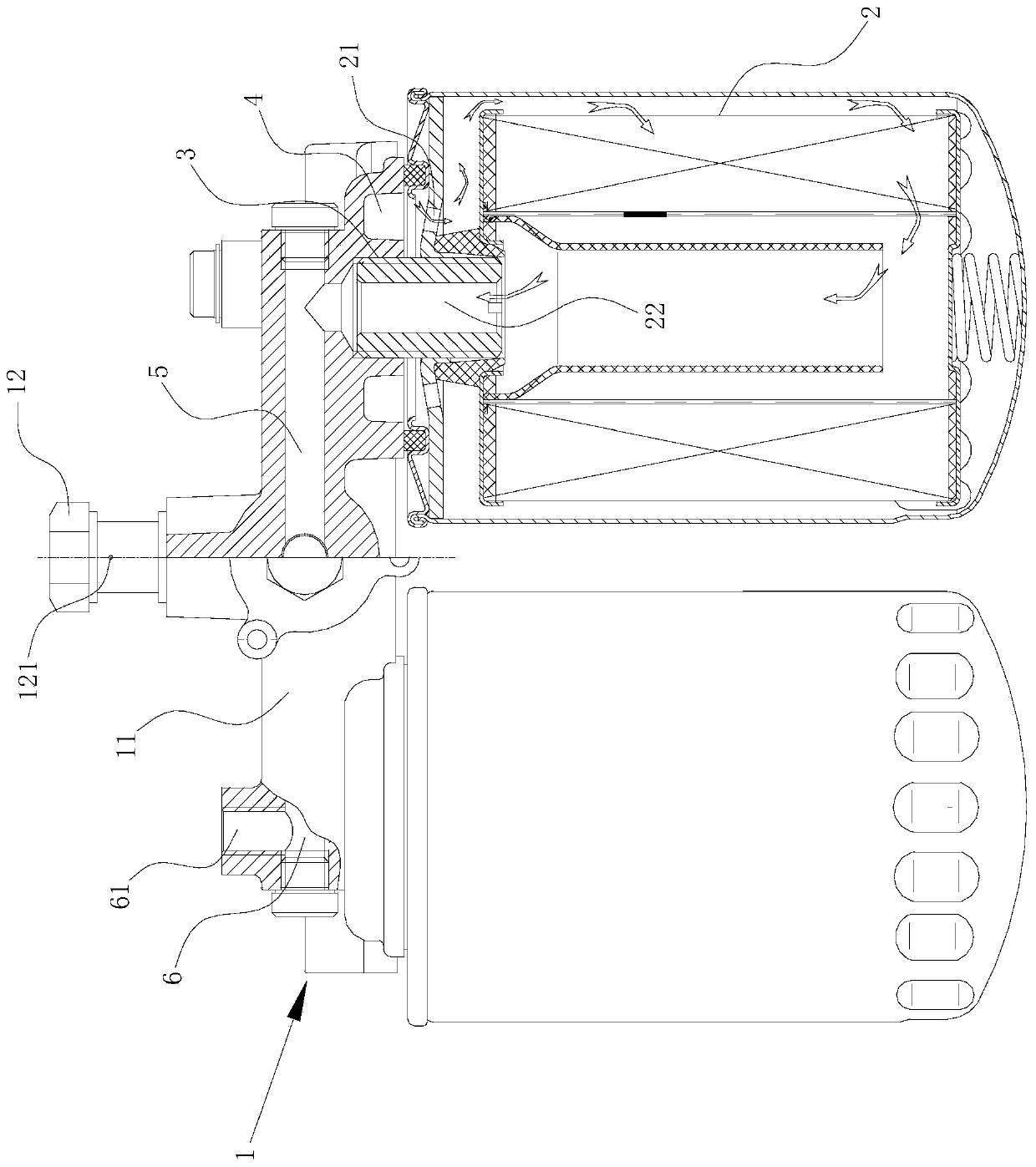

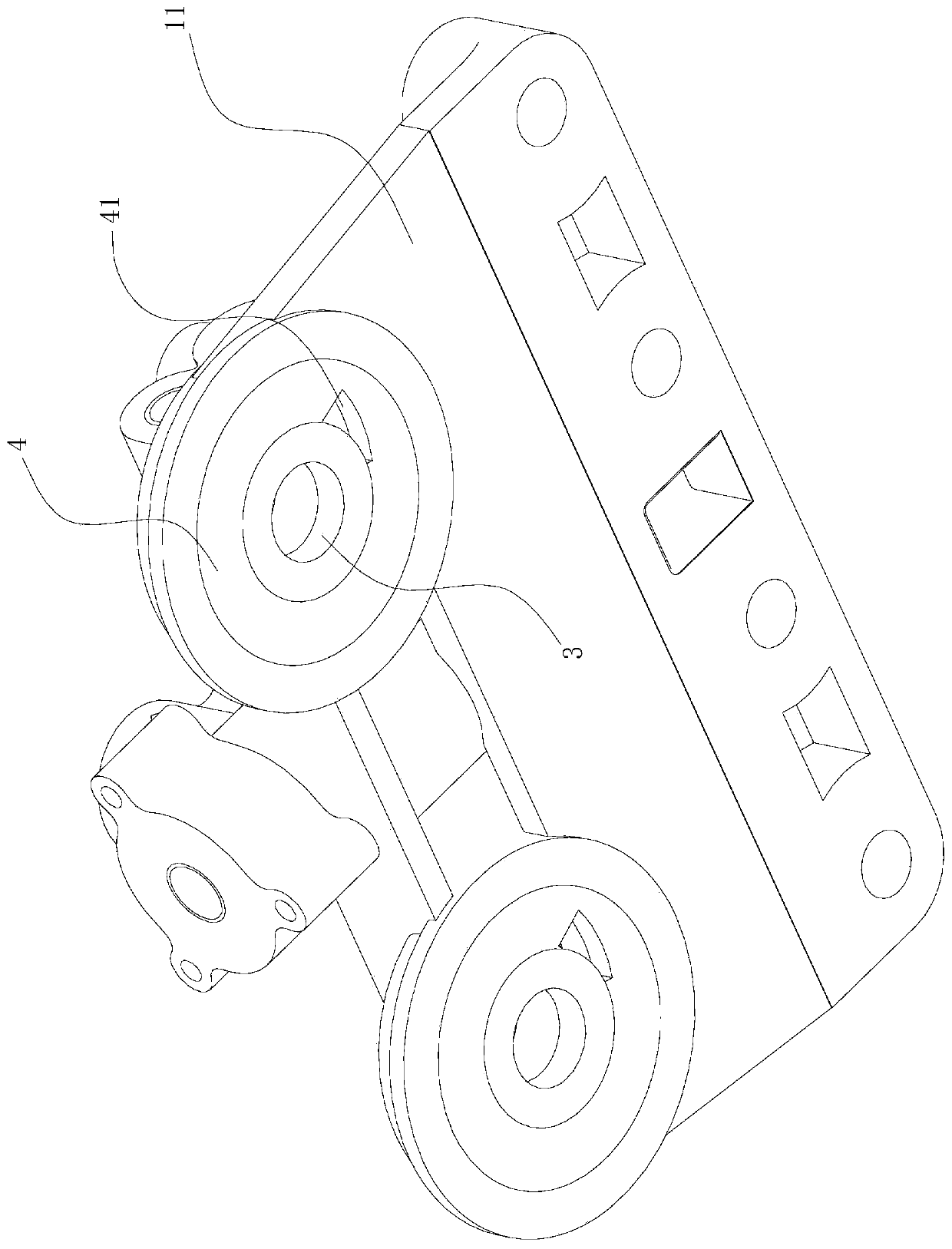

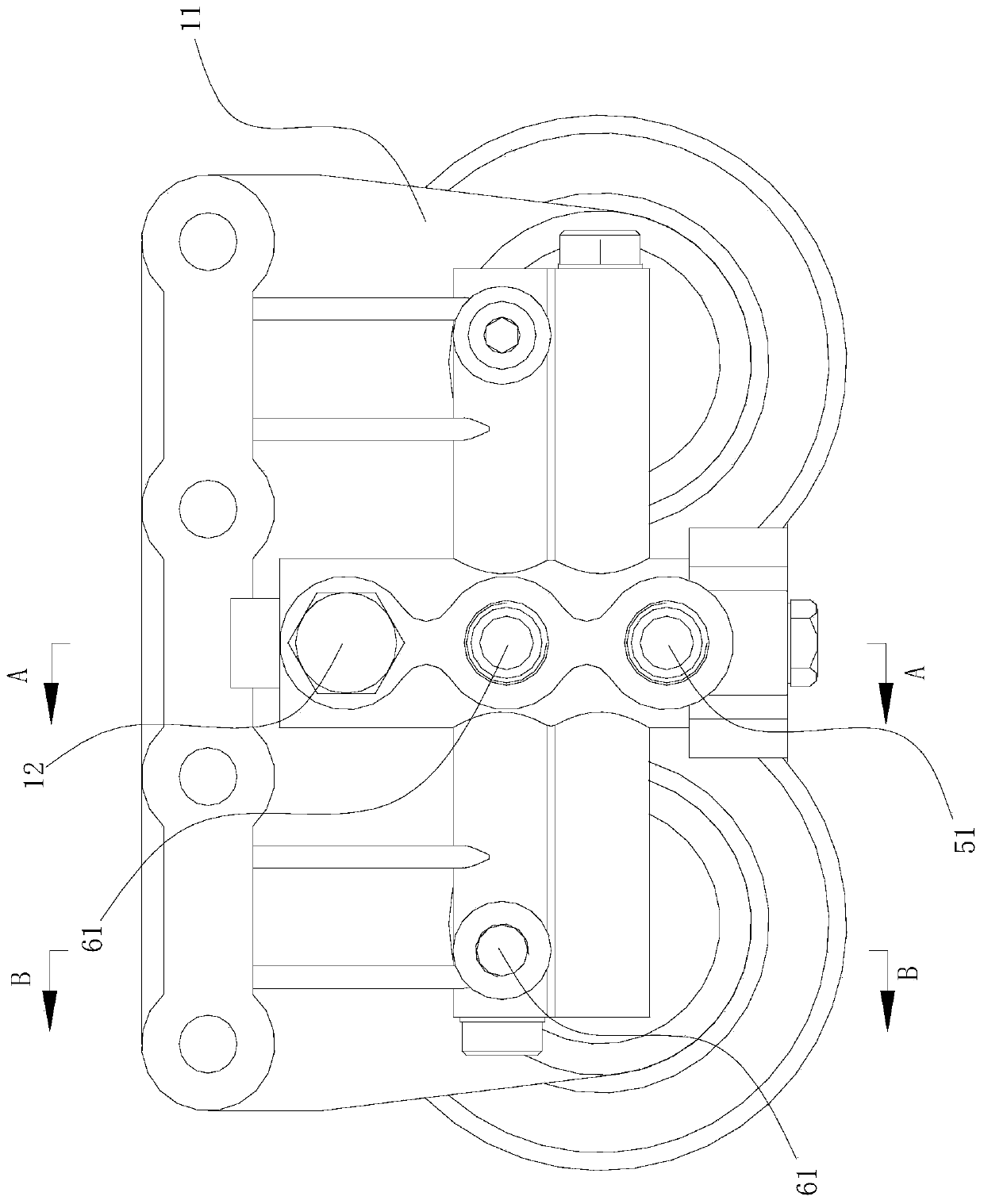

[0016] see Figure 1-Figure 5 , a large-flow fuel fine filter assembly, including a filter seat subassembly 1 and two fuel filter elements 2, the filter seat subassembly 1 includes a filter seat body 11, and the front part of the lower side of the filter seat body 11 There are two left-right symmetrical and vertically arranged threaded holes 3, and an annular groove 4 arranged around the threaded holes 3 is provided at the front position of the lower side of the filter seat body 11 corresponding to each threaded hole 3. The annular groove 4 The lower side is open, and the filter seat body 11 is provided with an oil outlet channel 5 and an oil inlet channel 6 that are arranged at intervals from front to back and are both left and right. The oil return channel 7 that is the same as the channel 6 and extends backward (in this embodiment, the oil inlet channel 6, the oil outlet channel 5, and the oil return channel 7 are all formed by drilling blind holes on the basis of the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com