Method for removing organic sulfur in coal by polar supercritical fluid

A supercritical fluid, organic sulfur technology, used in separation methods, chemical instruments and methods, solid fuels, etc., to achieve the effects of strong polarity, flame retardant price, and high diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

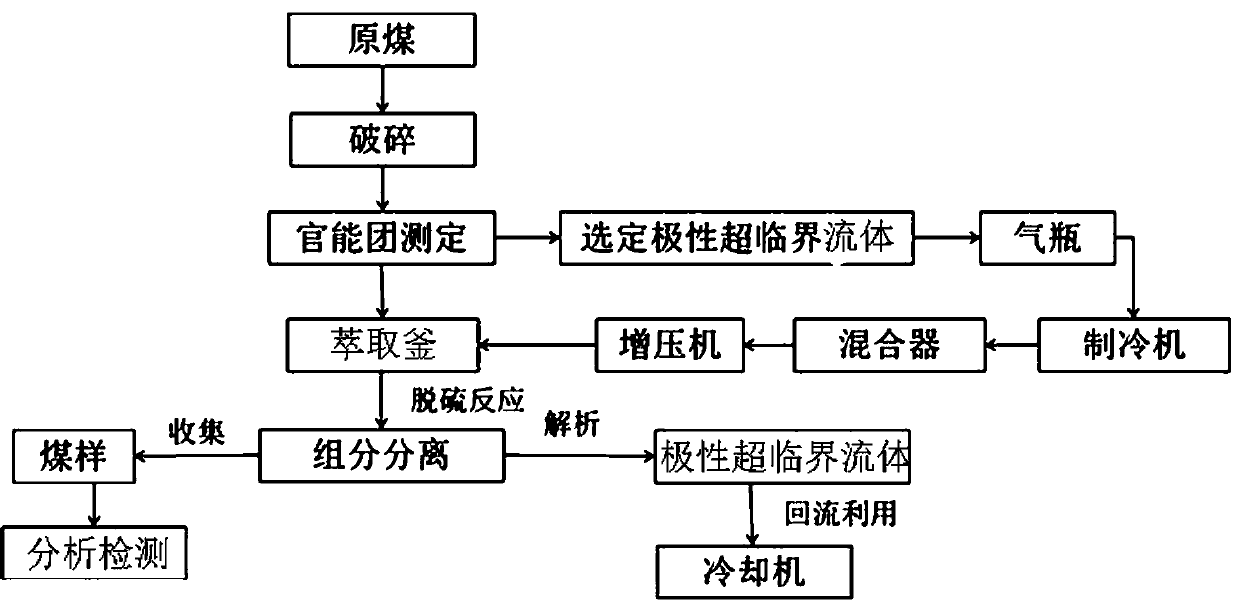

Image

Examples

Embodiment 1

[0016] Example 1: A method for removing organic sulfur in coal by polar supercritical fluid, including the following steps:

[0017] , Coal sample pretreatment: coal sample (the coal sample can be selected as Shanxi Gaoyang raw coal or Tangshan Kailuan raw coal) After selection, the coal sample is crushed to a particle size of 1 mm to obtain a suitable particle size, geometric shape and specific surface area. Enhance desulfurization effect;

[0018] , Coal sample determination: Determine and analyze the total sulfur content and organic sulfur in the coal sample after crushing by titration, determine the chemical bond type and polarity of the -C-S- bond in the organic sulfur, and select CO 2 Mix a small amount of alcohol liquid as a polar supercritical fluid, set the reaction condition as CO 2 Above the critical temperature and critical pressure, that is, above 31.26℃ and above 7.38MPa; the amount of alcohol liquid is small, so only CO is considered 2 The critical temperature and c...

Embodiment 2

[0023] Example 2: A method for removing organic sulfur in coal by polar supercritical fluid, including the following steps:

[0024] , Coal sample pretreatment: coal sample (the coal sample can be selected as Shanxi Gaoyang raw coal or Tangshan Kailuan raw coal) After selection, the coal sample is crushed to a particle size of 3mm to obtain a suitable particle size, geometric shape and specific surface area. Enhance desulfurization effect;

[0025] , Coal sample determination: Determine and analyze the total sulfur content and organic sulfur in the coal sample after crushing by titration, determine the chemical bond type and polarity of the -C-S- bond in the organic sulfur, and select CO 2 Mix a small amount of water or CO 2 Mix a small amount of aromatic liquid as a polar supercritical fluid, set the reaction condition as CO 2 Above the critical temperature and pressure, namely above 31.26℃ and above 7.38MPa; the amount of water or aromatic liquid is small, so only CO is consider...

Embodiment 3

[0030] Example 3: A method for removing organic sulfur in coal by polar supercritical fluid, including the following steps:

[0031] , Coal sample pretreatment: coal sample (coal sample can be selected as Shanxi Gaoyang raw coal or Tangshan Kailuan raw coal) After selection, the coal sample is crushed to a particle size of 2mm to obtain a suitable particle size, geometric shape and specific surface area. Enhance desulfurization effect;

[0032] , Coal sample determination: Determine and analyze the total sulfur content and organic sulfur in the coal sample after crushing by titration, determine the chemical bond type and polarity of the -C-S- bond in the organic sulfur, and select CO 2 A small amount of alkane gas is mixed as a polar supercritical fluid, the alkane gas is ethane or propane, and the reaction conditions are set to CO 2 Above the critical temperature and pressure, that is, above 31.26℃ and above 7.38MPa; the amount of alkane gas is small, so only CO is considered 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com